Heavy metal zero-emission treatment system and working method thereof

A treatment system and zero-discharge technology, applied in the direction of sludge treatment, filtration treatment, sedimentation treatment, etc., can solve the problems of residual discharge and incomplete treatment, and achieve the effect of water saving and recycling, simple structure and water purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

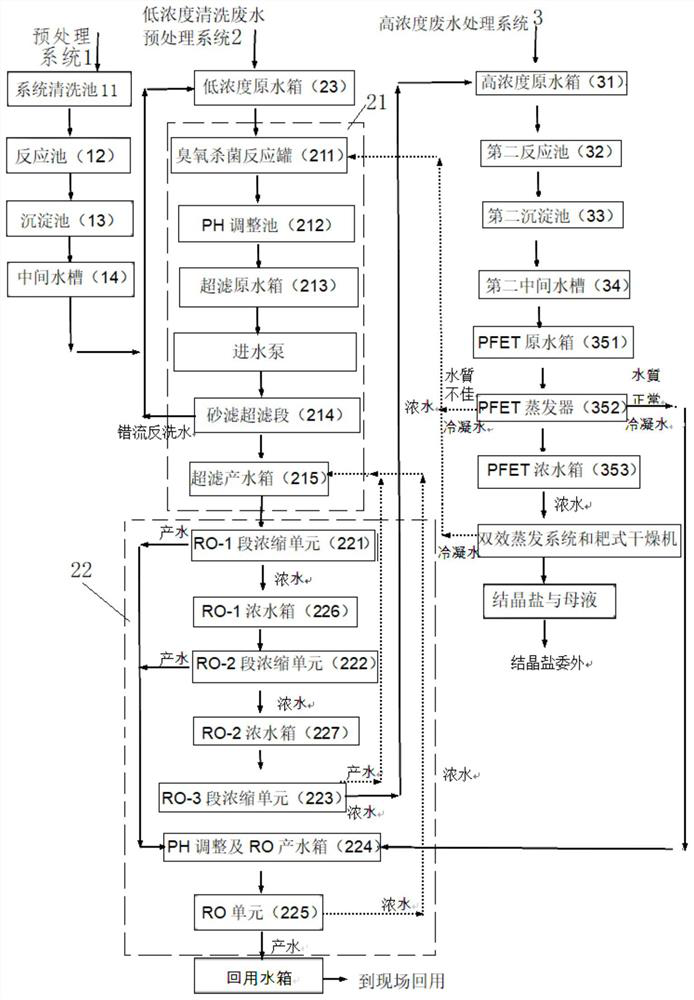

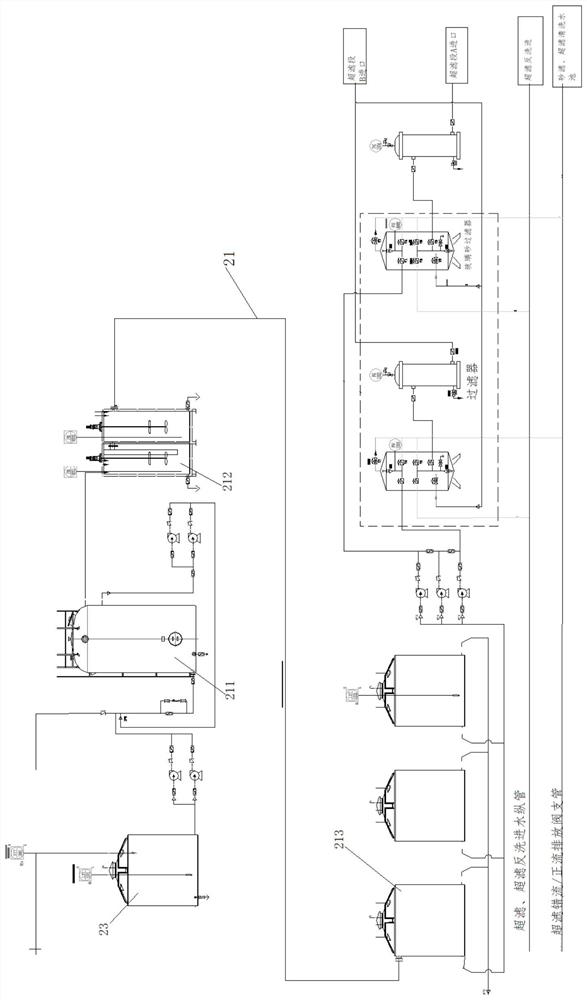

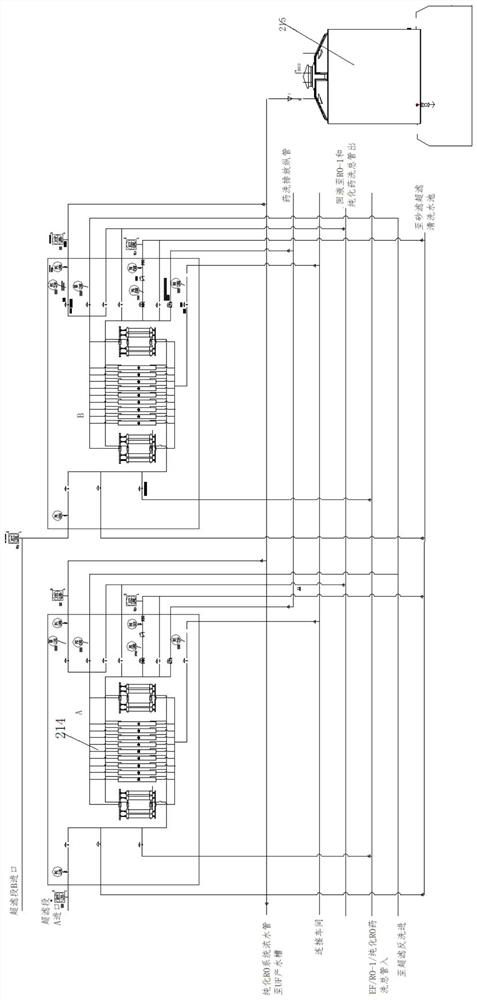

[0057] As shown in the figure, a heavy metal zero-discharge treatment system includes: a pretreatment system 1, a low-concentration cleaning wastewater pretreatment system 2, and a high-concentration wastewater treatment system 3. The low-concentration cleaning wastewater pretreatment system 2 includes sterilization, ultra- Filtration unit 21 and multi-stage RO concentration unit 22, the output end of the pretreatment system 1 is connected to the water inlet of the sterilization and ultrafiltration unit 21, and the output end of the sterilization and ultrafiltration unit 21 is connected to the multi-stage RO concentration unit 22 The output end of the multi-stage RO concentration unit 22 is connected to the input end of the high-concentration wastewater treatment system 3 .

[0058] The pretreatment system 1 described in this embodiment comprises a system cleaning tank 11, a reaction tank 12, a sedimentation tank 13 and an intermediate water tank 14, the output end of the syste...

Embodiment 2

[0065] As shown in the figure, a heavy metal zero-discharge treatment system includes: a pretreatment system 1, a low-concentration cleaning wastewater pretreatment system 2, and a high-concentration wastewater treatment system 3. The low-concentration cleaning wastewater pretreatment system 2 includes sterilization, ultra- Filtration unit 21 and multi-stage RO concentration unit 22, the output end of the pretreatment system 1 is connected to the water inlet of the sterilization and ultrafiltration unit 21, and the output end of the sterilization and ultrafiltration unit 21 is connected to the multi-stage RO concentration unit 22 The output end of the multi-stage RO concentration unit 22 is connected to the input end of the high-concentration wastewater treatment system 3 .

[0066] The pretreatment system 1 described in this embodiment includes a system cleaning tank 11, a reaction tank 12, a sedimentation tank 13 and an intermediate water tank 14, the output end of the system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com