Continuous chemical reaction system and method for arylboronic acid ester synthesis through micro-fluidic chip under flowing

A microfluidic chip, aryl boronate technology, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, organic chemistry, etc. , increase in energy consumption, etc., to achieve the effect of ultra-miniaturization of equipment, ultra-miniaturization of high-strength and high-efficiency equipment, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

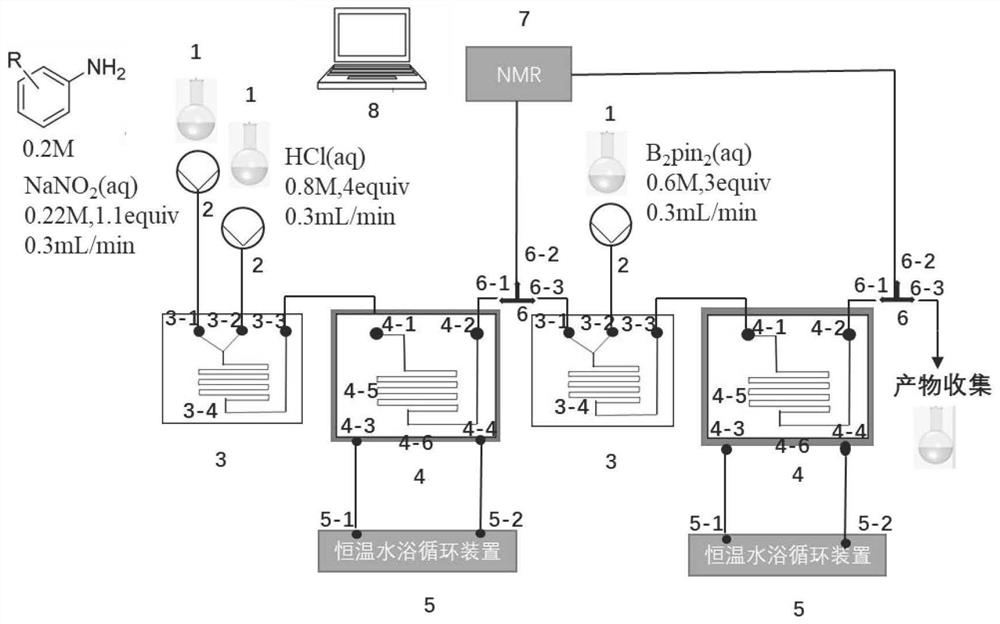

[0058] The invention provides a flow chemical reaction system for preparing diazonium salt on demand at room temperature through a microfluidic chip under flow and on this basis by reacting with biboronic acid pinacol ester to synthesize aryl borate ,Such as figure 1 As shown, it includes: a microfluidic chip preparation diazonium salt reaction module, a microfluidic chip aryl borate synthesis module, and an online monitoring module.

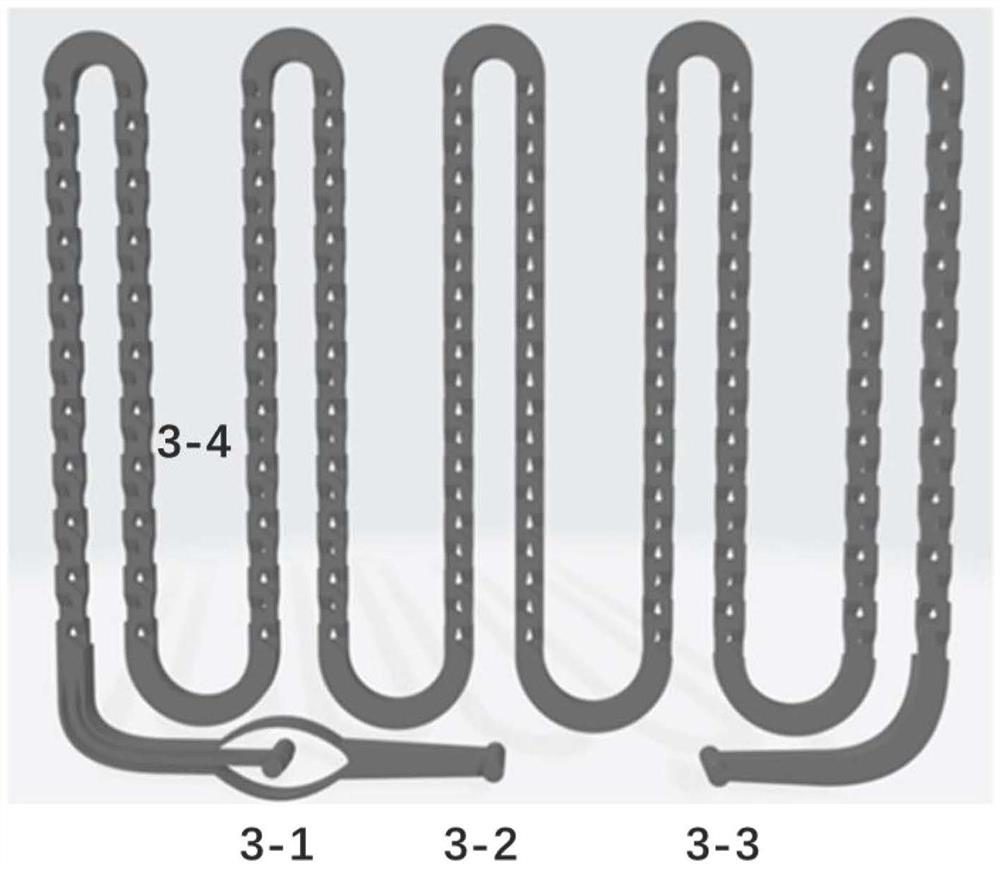

[0059] The microfluidic chip preparation diazonium salt reaction module includes: a sample bottle 1, a high-efficiency liquid phase infusion pump 2, a 3D mixing chip 3, a temperature-controllable reaction chip 4, a constant temperature circulating water bath device 5, and a fluid switching valve 6; Said reaction module is used for rapidly synthesizing diazonium salt at room temperature;

[0060] The microfluidic chip aryl borate synthesis module includes: a sample bottle 1, a high-efficiency liquid phase infusion pump 2, a 3D mixing chip 3, a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com