Radiation curable ink jet composition and ink jet method

A curing type, radiation technology, applied in the direction of copying/marking method, ink, printing, etc., can solve the problems of high viscosity, low viscosity of destructive acrylate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

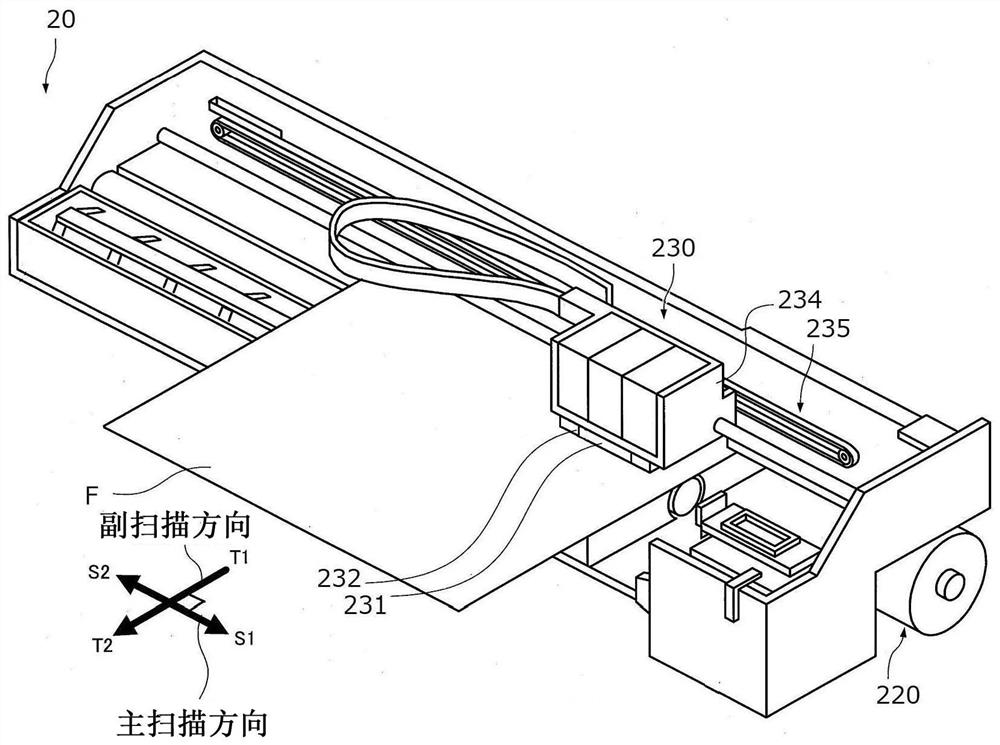

Image

Examples

Embodiment

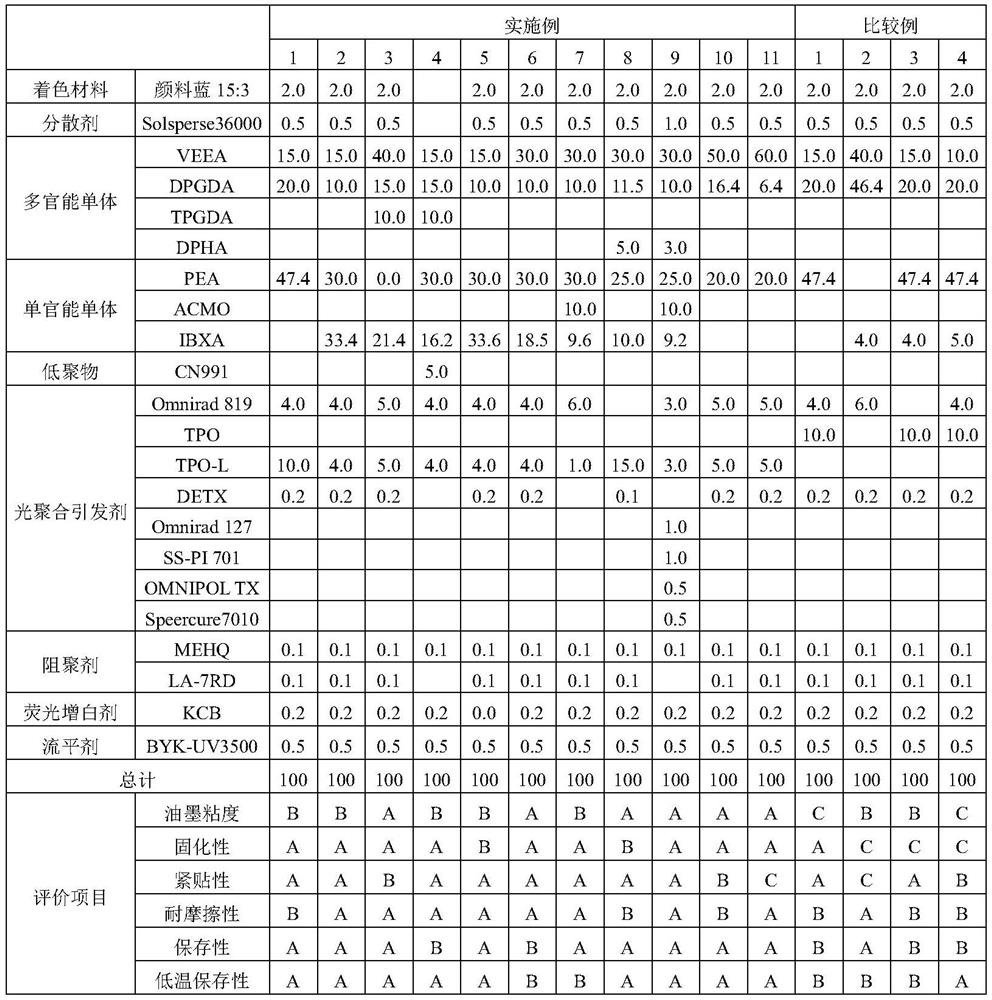

[0119] Hereinafter, the present invention will be described more concretely using examples and comparative examples. The present invention is not limited by the following examples.

[0120] 1. Preparation of Inkjet Composition

[0121] First, weigh a color material, a dispersant, and a part of each monomer, and put it into a tank for pigment dispersion. Ceramic grinding beads with a diameter of 1 mm are placed in the tank and stirred, thereby obtaining the monomer in the monomer. Pigment dispersion for dispersing colored materials in medium. Next, put the remaining monomer, photopolymerization initiator and polymerization inhibitor into a tank for a mixture as a stainless steel container according to the components listed in Table 1, and mix and stir to dissolve it completely, and then , the above-obtained pigment dispersion liquid was added, further mixed and stirred at room temperature for 1 hour, and further filtered using a 5 μm membrane filter, thereby obtaining the rad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com