Colored household paper and preparation method thereof

A household paper and color technology, applied in the field of papermaking, can solve the problems of large amount of dye, weak dyeing, uneven dyeing, etc., and achieve the effects of uniform dyeing, firm bleeding, and firm light fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

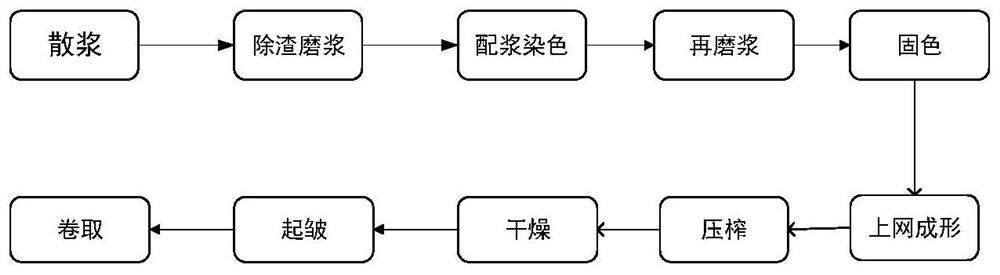

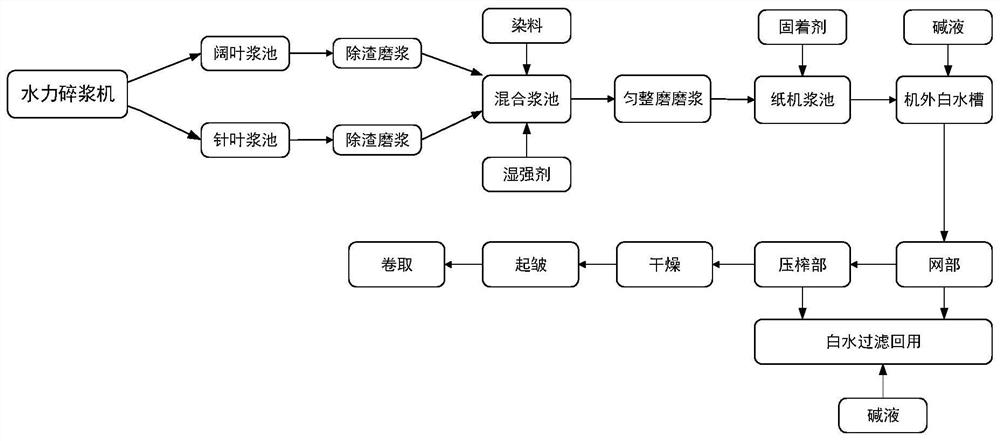

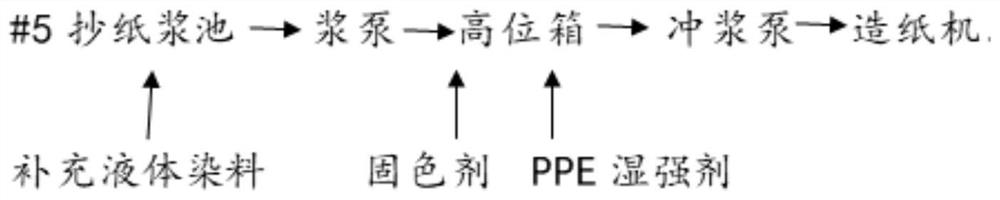

Method used

Image

Examples

Embodiment 1

[0062] Prepare 13 g / ㎡ tissue paper, Garnet Red as described above.

[0063] The bleached kraft hardwood pulp is eucalyptus eucalyptus pulp with an aspect ratio of 48.

[0064] The bleached kraft softwood pulp is Korean pine: spruce wood pulp (7:3), aspect ratio 80.

[0065] The mass ratio of bleached kraft softwood pulp: bleached kraft hardwood pulp is 35:65.

[0066] The degree of beating of the bleached kraft hardwood pulp is 22°SR, and the concentration: 4.2% by mass.

[0067] Freeness of bleached kraft softwood pulp: 27°SR, concentration: 4.5% by mass.

[0068] Even beating degree: 32°SR, concentration: 3.5% by mass.

[0069] Paper machine speed: 1500m / min, crepe rate 11%.

[0070] The used direct dye model: Scarlet R, directly diluted with condensed water to a 6.5% by mass solution after filtration and added for use. The flow rate of the liquid supply pump is 13200ml / min.

[0071] The fixing agent uses aluminum sulfate: the incoming material concentration is 8% by m...

Embodiment 2

[0078] A 15 g / ㎡ tissue paper, purple, was prepared as described above.

[0079] The bleached kraft hardwood pulp is eucalyptus pulp, mainly (blue eucalyptus, bright fruit eucalyptus) = 8:2, aspect ratio 52.

[0080] Bleached kraft softwood pulp is radiata loose pulp with an aspect ratio of 83.

[0081] The mass ratio of bleached kraft softwood pulp: bleached kraft hardwood pulp is 30:70.

[0082] The degree of beating of the bleached kraft hardwood pulp is 22°SR, and the concentration: 4.2% by mass.

[0083] The bleached kraft softwood pulp has a beating degree of 30°SR and a concentration of 4.5% by mass.

[0084] Even beating degree: 35°SR, concentration: 3.5% by mass.

[0085] Paper machine speed: 1400m / min, crepe rate 12%.

[0086] The model of the direct dye used: Violet B, directly diluted with condensed water to be 6.5% by mass solution after filtration and added for use. The flow rate of the liquid supply pump is 11500ml / min.

[0087] The fixing agent uses alumin...

Embodiment 3

[0094] 18 g / ㎡ tissue paper, light green, was prepared as described above.

[0095] The bleached kraft hardwood pulp is eucalyptus pulp, mainly (blue eucalyptus, bright fruit eucalyptus) = 8:2, aspect ratio 52.

[0096] Bleached kraft softwood pulp is radiata loose pulp with an aspect ratio of 83.

[0097] The mass ratio of bleached kraft softwood pulp: bleached kraft hardwood pulp is 26:74.

[0098] The degree of beating of the bleached kraft hardwood pulp is 20°SR, and the concentration is 4.2% by mass.

[0099] Freeness of bleached kraft softwood pulp: 30°SR, concentration: 4.5% by mass.

[0100] Even beating degree: 30°SR, concentration: 3.4% by mass.

[0101] Paper machine speed: 1100m / min, crepe rate 13%.

[0102] The type of direct dye used: light green N, directly diluted with condensed water to a 6.5% by mass solution and added after filtration. The flow rate of the liquid supply pump is 8500ml / min.

[0103] The fixing agent uses aluminum sulfate: the incoming ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com