Method of grouting waterproof curtain in leakage treatment of rail transit underground platform

A technology for rail transit and waterproof curtains, applied in construction, infrastructure engineering, etc., can solve problems such as poor plugging effect, failure to meet safe use requirements, and difficulty in achieving it, so as to improve bearing capacity, control structural water leakage, Controlling the effect of settling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

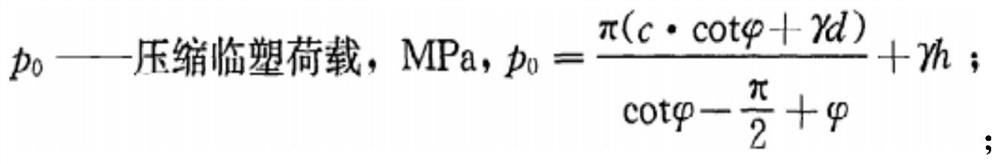

[0115] Example 1 Determination of hole spacing and row spacing for silt grouting reinforcement, on-site drilling sampling confirmation analysis, permeability coefficient k is 4×10 -3 cm / sec, the porosity is 30-50% and n is 40%, the slurry viscosity α is 1.2 centipoise, the grouting hole Φ3.2-4.0cm is taken as r radius 2.0cm, the grouting pressure is 0.4-0.8MPa and h is 0.5MPa, That is, the water head is 5000cm, the time is 5-15 minutes, and t is 15 minutes, that is, 900 seconds. Calculate the slurry diffusion radius according to the Mag formula as follows:

[0116] R=((3krht / nα)+r 3 ) 1 / 3 =((3×4×10 -3 ×2×5000×900) / (0.4×1.2)+2 3 ) 1 / 3 = 60.82 cm.

[0117] (2) Layout of grouting holes

[0118] Grouting hole spacing and row spacing The grouting holes are distributed in a quincunx shape, and the tentative grouting hole spacing is 2.5m, which will be adjusted after trial grouting.

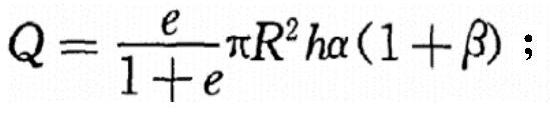

[0119] (3) The amount of grouting for grouting reinforcement in soft ground should be determ...

example 2

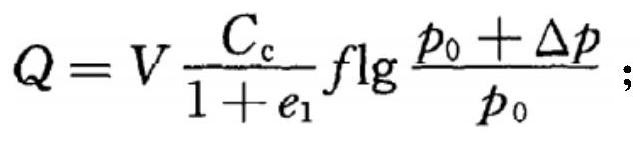

[0160] Example 2. Using the empirical method, the grouting penetration radius R = 1.500mm, the length of the grouting section h = 3.000mm, and the empirical coefficient 0.3;

[0161] Q=C 1 V

[0162] =1.5 2 ×3.14×3×0.3

[0163] 6.35m 3 .

[0164] The position, hole spacing, row spacing and depth of grouting holes for foundation reinforcement of existing buildings shall be determined according to on-site grouting tests, and dynamic construction shall be carried out during the grouting process, and monitoring shall be done during the construction process.

[0165] pulp preparation

[0166] The mixing position of ultra-fine cement slurry-modified water glass should be determined according to the initial setting time of the slurry. When the initial setting time is greater than 2 minutes, it should be mixed at the orifice; when the initial setting time is less than 2 minutes, it should be mixed in the hole or at the bottom of the hole.

[0167] (1) Dilution of modified water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com