Manufacturing method of high-light-concentration high-resolution variable-conical-surface bent crystal

A manufacturing method and high-resolution technology, applied in the analysis of materials, material analysis using wave/particle radiation, measuring devices, etc., can solve the problems of limited detection, small conical curvature radius, and long position, and improve the surface shape Precision, high light collection efficiency, and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

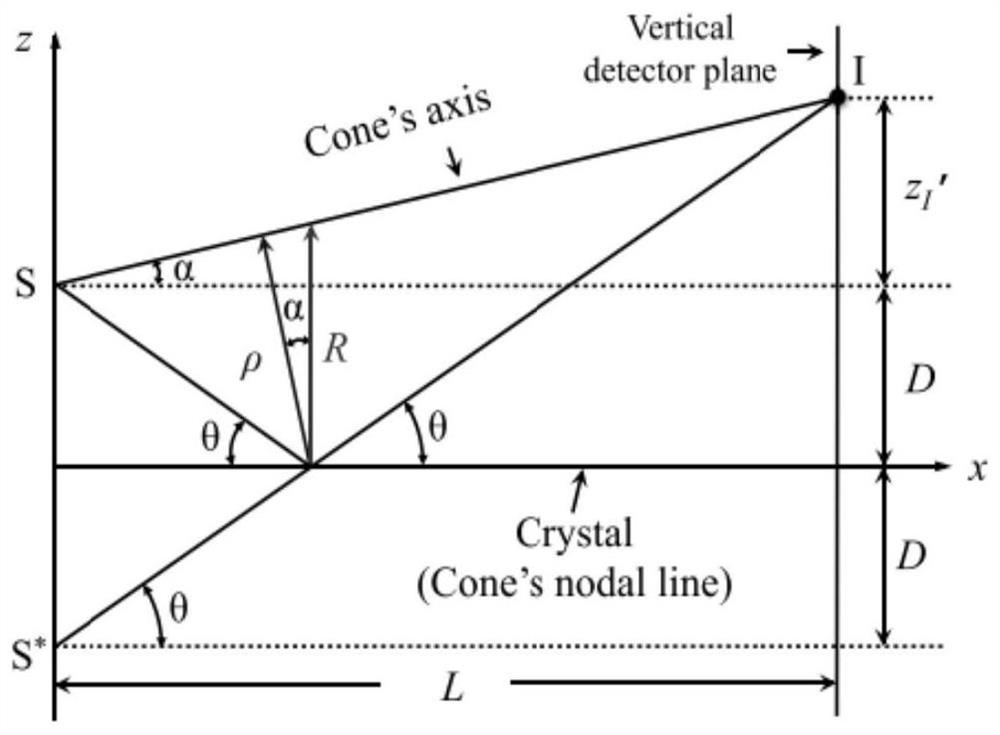

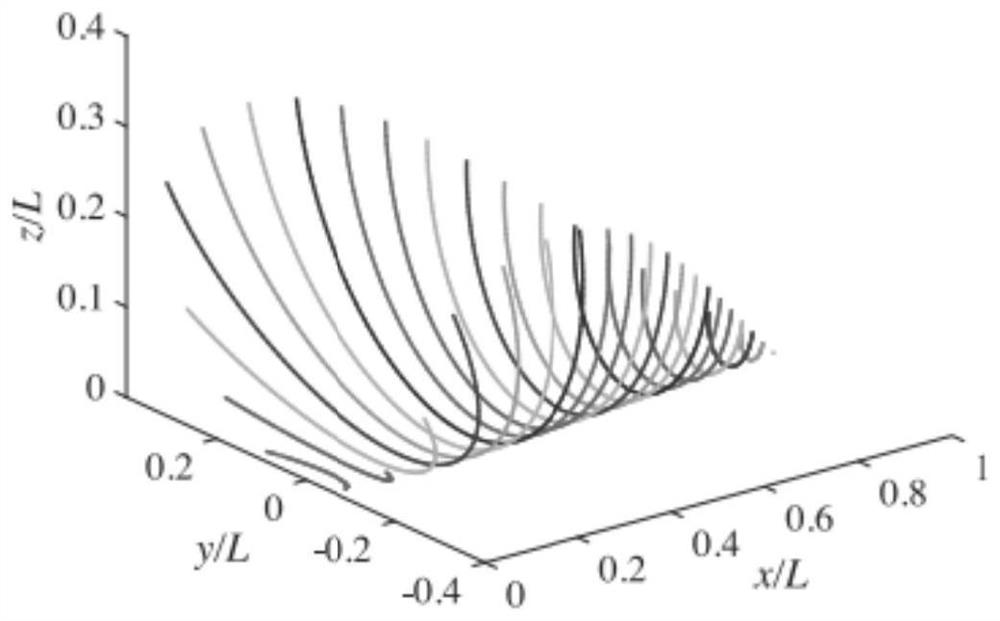

[0041] The method of modeling in step S1 is: use each theoretical circular arc as the contour line, X-axis and three guiding lines on both sides of the X-axis to form a surface, and draw the corresponding circular arc at each coordinate point of the X-axis, Make two endpoints of each arc at the Z coordinate, respectively connect each endpoint of the arc at the two endpoints on the Z coordinate, and make two splines to complete the modeling.

[0042] For example:

[0043] Take X coordinates: 253.00, 253.01, 253.02, 253.03...313.00;

[0044] Take the Z coordinates: -30, +30;

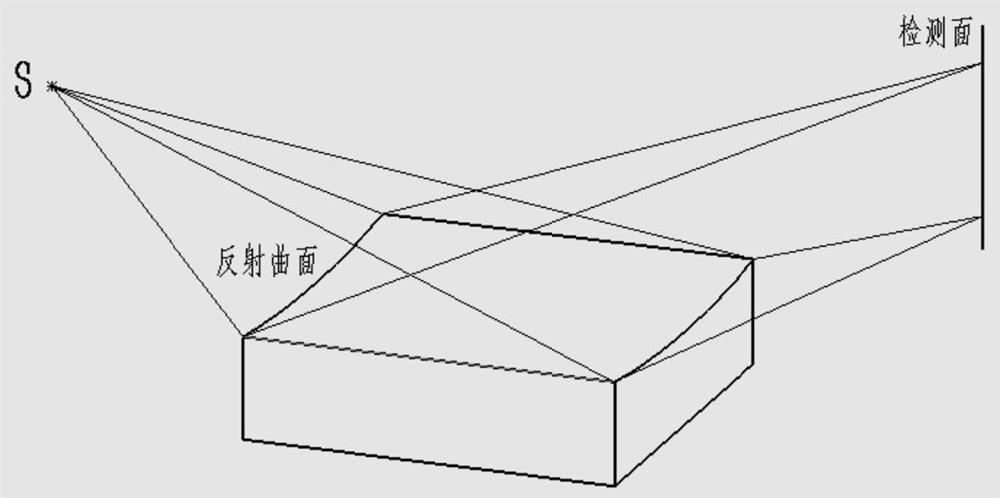

[0045] At each coordinate point of the X axis, draw the corresponding arc lines, draw the two end points of each arc when the Z coordinates are -30 and 30, and connect the arcs at Z=-30 and Z=30 respectively At the end point, make two splines, the two splines and the X-axis are used as the guide line when forming a surface, and the reflection surface is composed of the guide line and the contour lines of...

Embodiment 2

[0047] The method for three-coordinate machine measurement in step S4 is: the XYZ coordinates of the measurement points are generated earlier before the three-coordinate measurement, the numerical control processing module of the three-dimensional software is used to generate the NC program, and the established three-dimensional model is used to set the distance of the measurement point, the spherical measurement point First, use the processing module to generate the NC processing program. After running the program, the coordinates of the starting point of tool processing on the program are the XYZ theoretical coordinates of the point required by the measurement surface shape. Use these coordinate values as the three coordinates to set the position of the measuring point, and get the theoretical The surface shape difference between the Z coordinate and the measured Z coordinate;

[0048]For example, when using UG software, the method is as follows: use the established 3D mode...

Embodiment 3

[0050] In step S6, the method of adopting high-precision surface shape to keep the positioning pressing block molding and shaping includes: after the substrate and the wafer are cleaned, the substrate is fixed on the workbench, and ultraviolet glue is coated on it. Gently place the wafer on the glue, and align the positioning block and lightly compact it to remove air bubbles. Press a weight of appropriate weight on it, keep it fixed, and bake it with a UV lamp for more than 24 hours. Take it out and clean it and leave it for later. test.

[0051] When gluing the wafer with the base, in order to ensure the surface shape accuracy of the curved crystal, under the condition that the base surface shape accuracy is appropriate, this embodiment adopts the method of high-precision surface shape holding and positioning pressing block molding and shaping, and uses the high-precision surface shape to keep the positioning. The surface shape of the briquetting block is used to ensure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com