Method for processing semiconductor wafer, semiconductor wafer, clip and semiconductor device

A technology for semiconductors and wafers, applied in the field of semiconductor devices, processing semiconductor wafers, and clamping pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

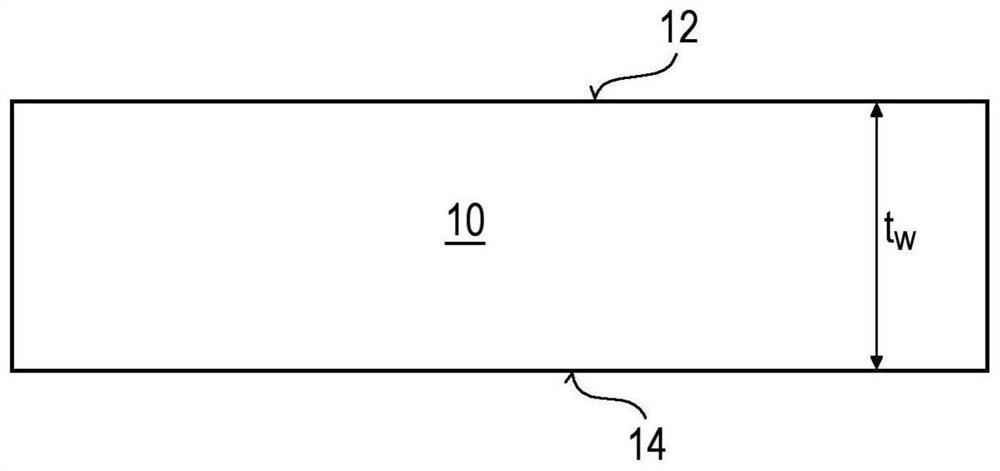

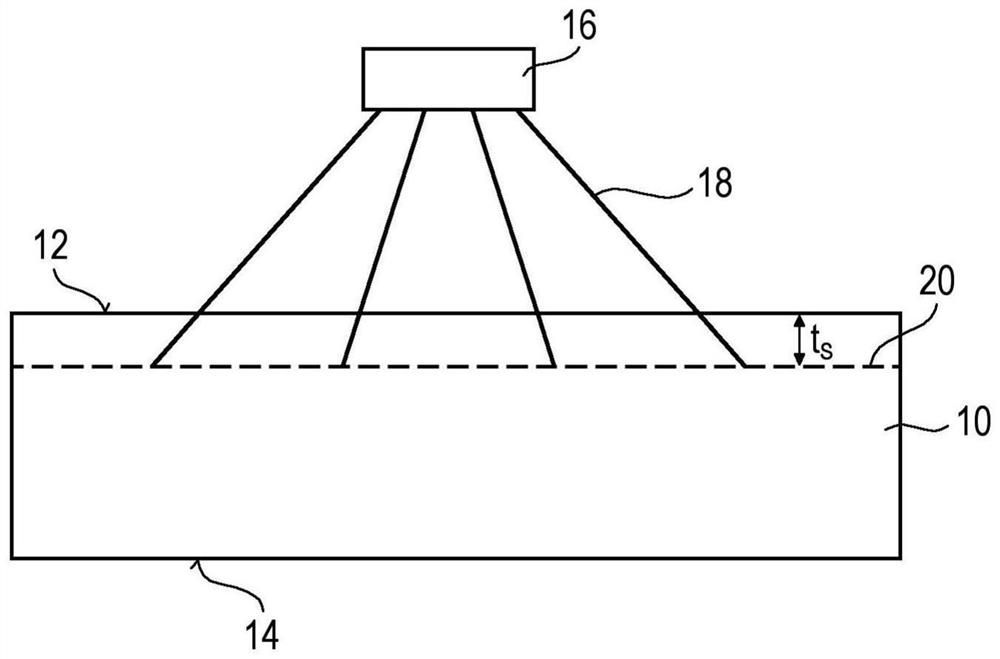

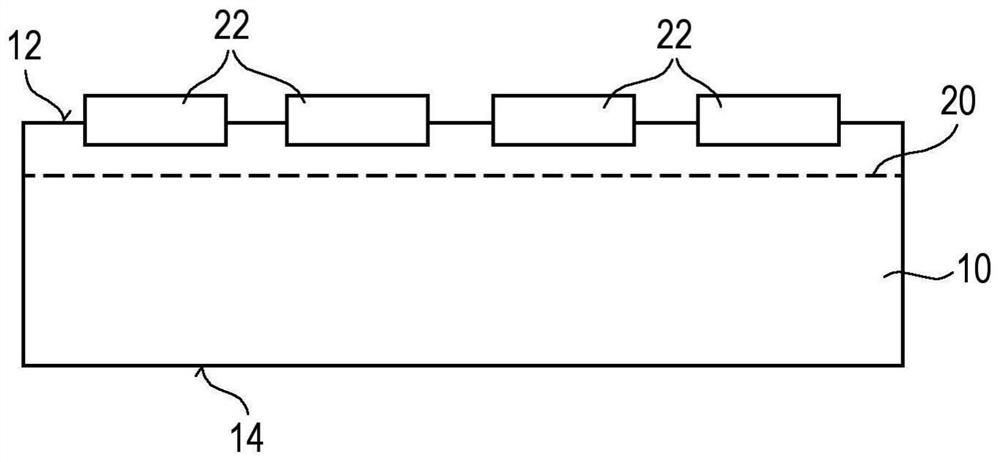

[0060] Example 1 is a method for processing a semiconductor wafer, the method comprising: providing a semiconductor wafer comprising a first main surface and a second main surface opposite to the first main surface; generating a defect inside the semiconductor wafer, the defect defining a breakaway plane parallel to the first major surface; processing the first major surface to define a plurality of electronic semiconductor components; providing a glass structure comprising a plurality of openings; attaching the glass structure to the processed The first major surface, each of the plurality of openings leaving a respective region of the plurality of electronic semiconductor components uncovered; applying a polymer layer to the second major surface; by cooling the polymer layer to its glass transition Below the temperature, the semiconductor wafer is split into semiconductor slices extending between the first main surface and the release surface and comprising a plurality of ele...

example 2

[0061] Example 2 is the method of example 1, wherein the method further comprises applying an additional polymer layer to the first major surface prior to cleaving the semiconductor slices from the semiconductor wafer.

example 3

[0062] Example 3 is the method of Example 1, wherein the thickness of the semiconductor slice is about 100 μm or less, preferably about 50 μm or less.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap