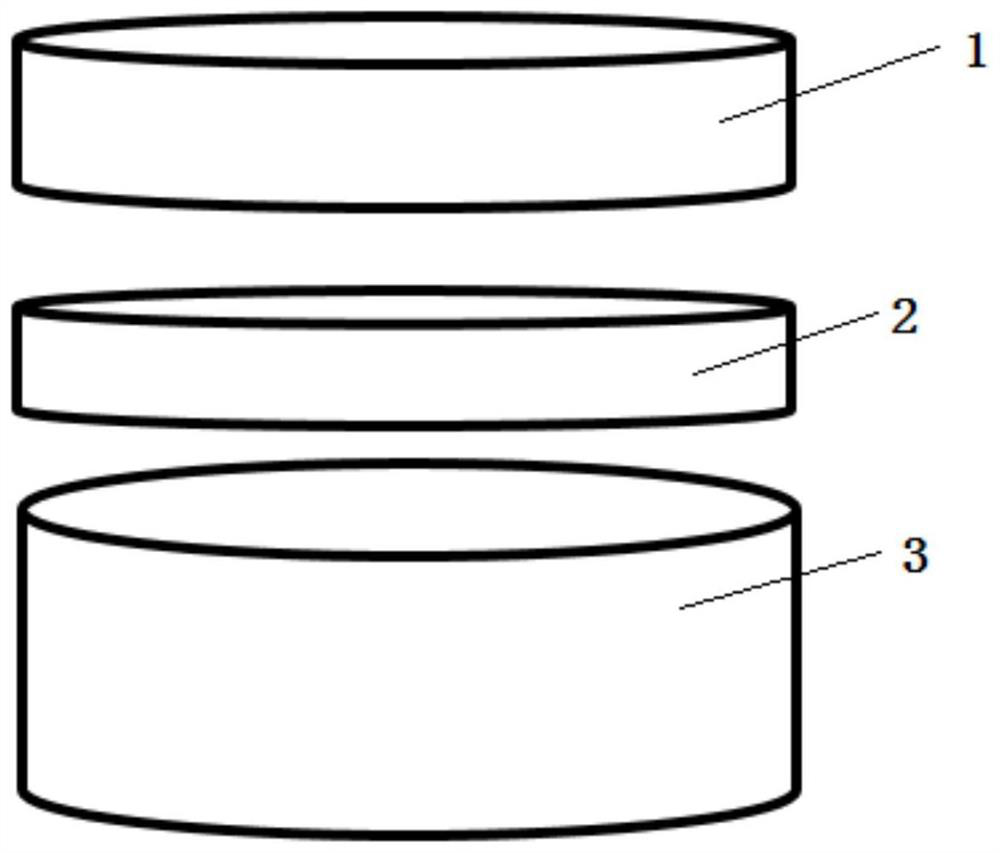

Osteochondral stent as well as preparation method and application thereof

A technology for osteochondral and cartilage layers, applied in the manufacture of tools, additive manufacturing, bone implants, etc., can solve the problems of insufficient capture cells, poor repair function of damage, etc., achieve simple clinical operation, prevent ossification, simple and practical sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0172] 1. Preparation of cartilage layer

[0173] (1) Synthesis of methacrylated gelatin (GelMA): Dissolve gelatin (1g) in 10mL PBS (pH=7.4), heat to 50°C and stir until completely dissolved, add 0.5mL methacrylic anhydride, reaction 2 ~3h, after the reaction, dilute the reaction solution with 40mL PBS, then pour it into a dialysis bag (MWCO7000), dialyze with deionized water for 2~3d, and freeze-dry to obtain methacryloyl esterified gelatin (0.9g). According to the H NMR spectrum ( 1 H NMR), select the integral area of phenylalanine standard peak (7.1~7.4ppm) as 1, calculate the percentage of peak area decline of lysine signal at 2.8~2.95ppm before and after gelatin modification, obtain methacrylic acid The degree of methacrylation of the acylated gelatin was 65%.

[0174] (2) Synthesis of methacrylylated hyaluronic acid (HAMA): dissolve hyaluronic acid (1g, 900kDa) in 100mL deionized water, cool to 0-4°C, add 5mL methacrylic anhydride, and slowly drop Add 5mL of 5M NaOH...

Embodiment 2

[0188] 1. Preparation of cartilage layer

[0189] (1) Synthesis of methacryloyl gelatin (GelMA): same as Example 1.

[0190] (2) Synthesis of methacrylylated hyaluronic acid (HAMA): same as Example 1.

[0191] (3) Preparation of 5% GelMA / 2% HAMA / 0.5% LAP hydrogel composition: same as Example 1.

[0192] (4) Preparation of cartilage layer by direct 3D printing method:

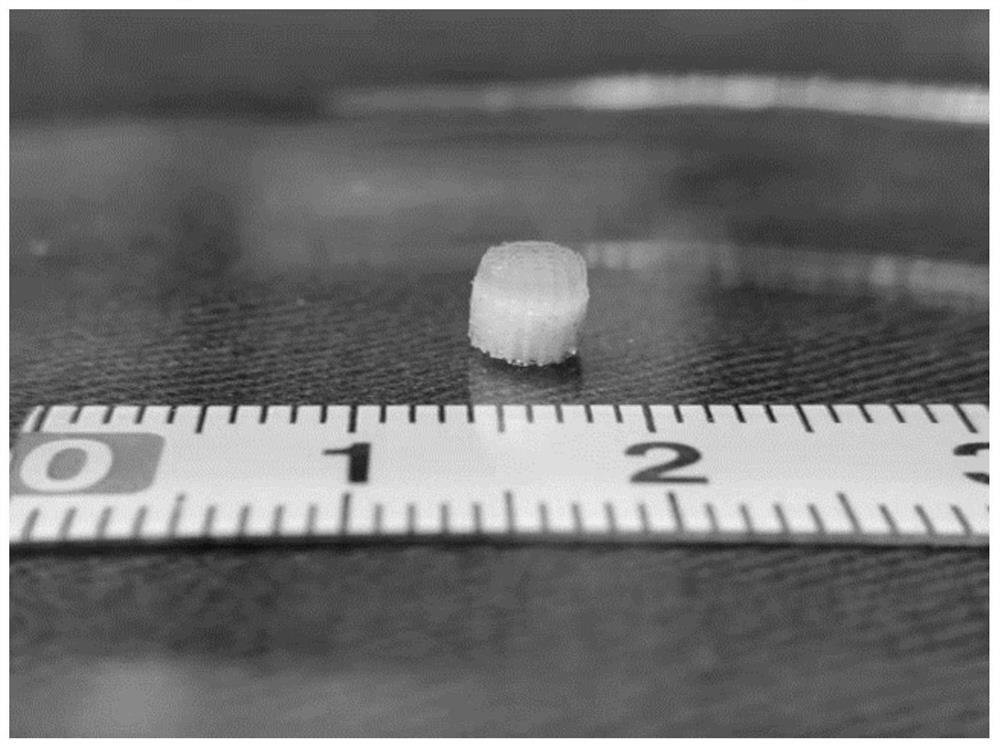

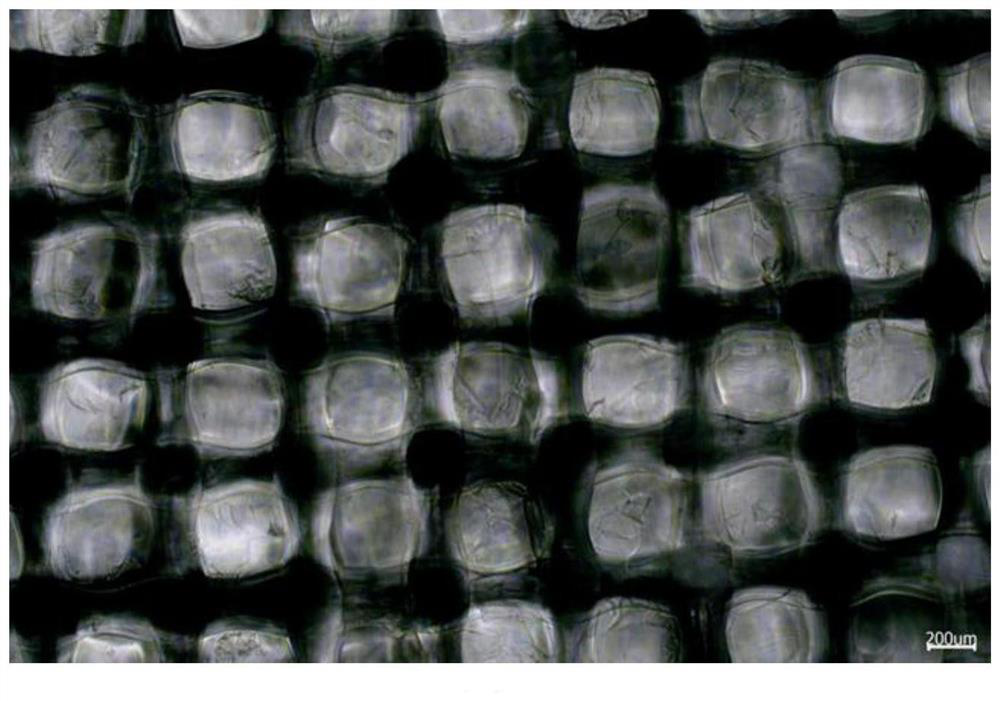

[0193] The above hydrogel composition was printed with an extrusion 3D printer, and was cured by blue light (insulation temperature: 37°C; platform temperature: 22°C; printing pressure: 20PSI; printing speed: 5mm / s; filling rate: 50%); The prepared GelMA / HAMA photo-crosslinked cured hydrogel was placed in a refrigerator at -20°C for 2 hours, and then lyophilized with a lyophilizer to obtain the GelMA / HAMA cartilage layer. The obtained GelMA / HAMA cartilage layer is a cylinder (5 mm in diameter and 1 mm in height), with a porosity of 50% and a pore diameter of 300 μm.

[0194] (5) Loading of TGFβ: Same as Exam...

Embodiment 3

[0200] 1. Preparation of cartilage layer

[0201] (1) Synthesis of methacryloyl gelatin (GelMA): same as Example 1.

[0202] (2) Preparation of sodium alginate / gelatin composite cross-linked hydrogel composition: Weigh 0.02g of sodium alginate (Alg), 0.05g of GelMA and 5mg of LAP and dissolve them in 1mL of PBS solution (pH=7.4). A hydrogel composition of 2% Alg / 5% GelMA / 0.5% LAP was prepared at ℃.

[0203] (3) The hydrogel composition is poured in the prefabricated mold, at 405nm wavelength, intensity 10mW / cm 2 Photocrosslinking is achieved under the irradiation of a light source; the formed hydrogel is taken out of the mold and placed in 0.1MCaCl 2 Soak in cold water for 2 hours to achieve chemical crosslinking, and the composite photocrosslinked cured hydrogel can be obtained; then, the prepared composite photocrosslinked cured hydrogel is placed in a -20°C refrigerator for 2 hours, and then frozen in a lyophilizer Dry to obtain the Alg / GelMA cartilage layer.

[0204] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com