Machine-made sandstone production workshop coarse aggregate flushing and pitch diameter online monitoring method

A production workshop and coarse aggregate technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve quality problems, affect crushing efficiency, lack of quality control methods, etc., to improve production efficiency and quality, The effect of protecting the ecological environment and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

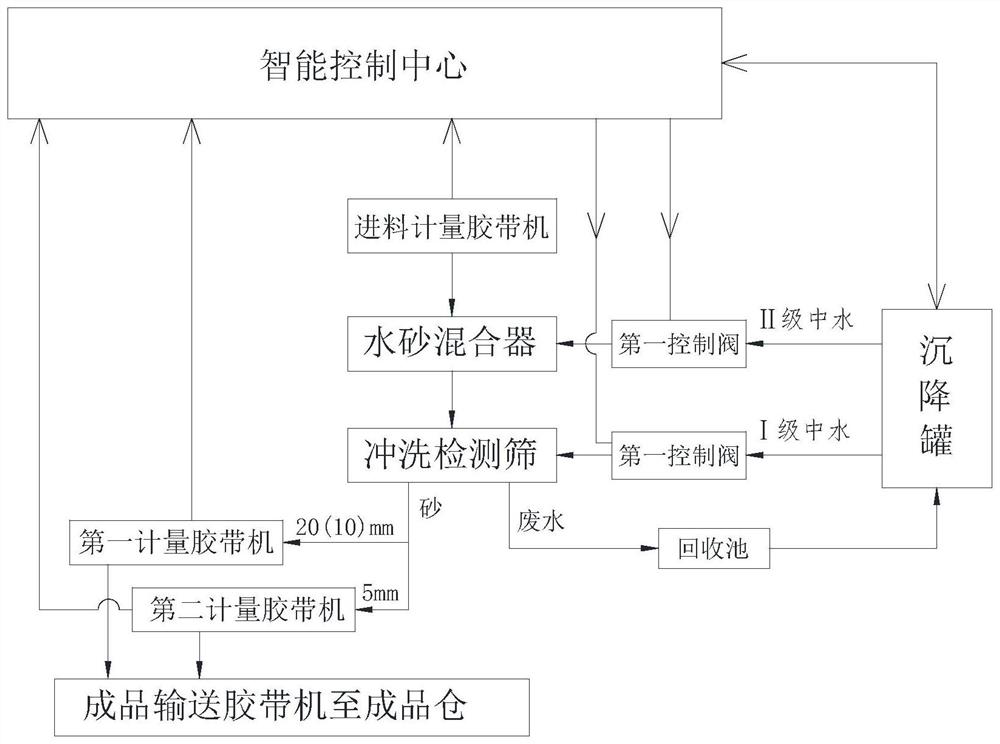

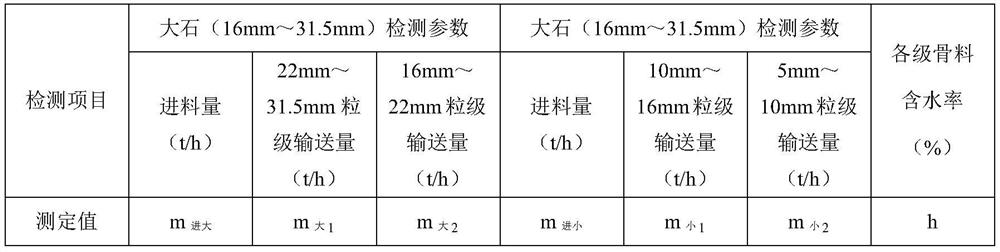

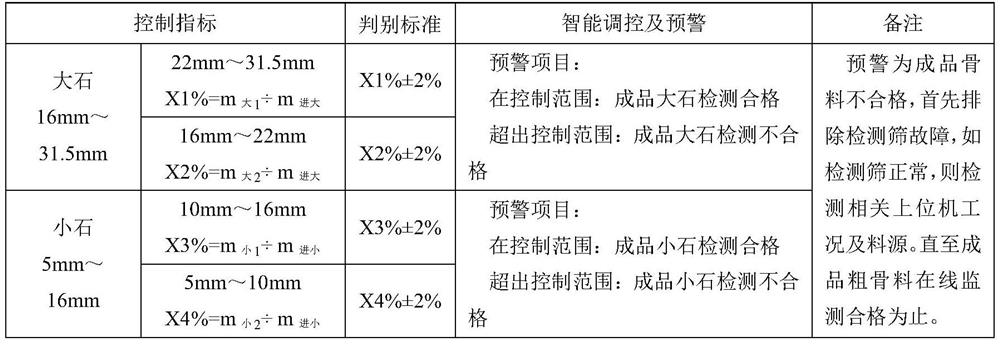

[0019] In order to ensure that the particle size of the subsequent crushing process is controllable, according to the calculation of the crushing gradation balance, it is necessary to ensure that the mass weight of the median diameter of the coarse aggregate is within the control range, and the median diameter of a single particle size is the upper limit and lower limit of the particle size The average value of , so it is necessary to control the proportion of single-grain weight, such as figure 1 As shown, a coarse aggregate flushing and medium-diameter online monitoring method in a machine-made sandstone production workshop. The coarse aggregate feed is divided into large stones and small stones according to particle size. The control system of the center presets the proportion of the weight of each particle size of the coarse ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com