Preparation method of multicolor fluorescent transparent wood based on carbon quantum dots and transparent wood

A technology of carbon quantum dots and fluorescence, which is applied in the field of transparent wood, can solve the problems of limited use, single fluorescence, and inability to change color, and achieve the effect of shortening the curing time and simplifying the curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

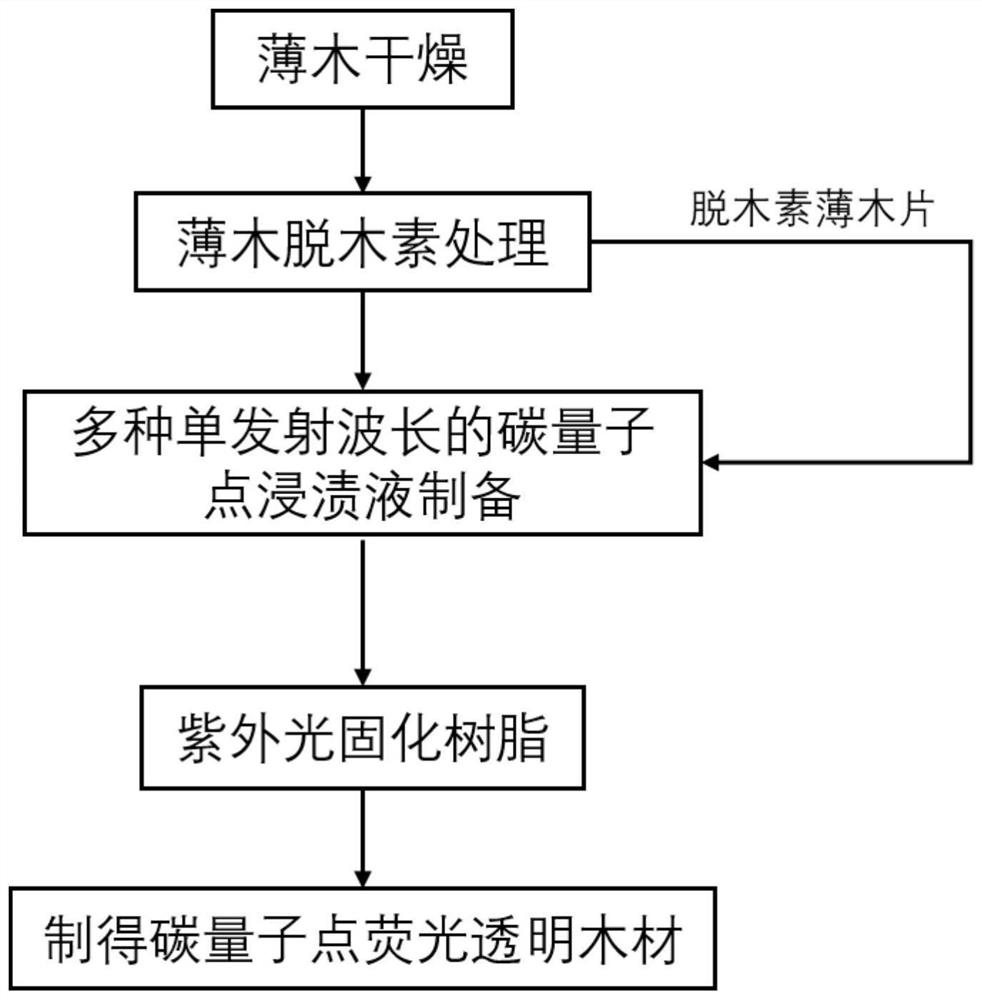

[0032] The preparation method of multi-color fluorescent transparent wood based on carbon quantum dots comprises the following steps:

[0033] (1): Select a poplar veneer sample with a size of 20mm*20mm*1.5mm, and dry it at 80°C for 12 hours to a dry state. The density of the veneer sample after drying is 0.087g / cm 3 spare;

[0034] (2): Mix 20g of sodium hypochlorite and 500ml of distilled water and stir evenly. Use glacial acetic acid to adjust the pH of the mixed solution to 4.6 to obtain a delignification aqueous solution. Soak 1.044g of veneer samples dried in step (1) in the delignification In the plain aqueous solution, heat in a water bath at 85°C for 8 hours for delignification treatment, until the veneer sample is white;

[0035] (3): The veneer sample that has been delignified in step (2) is taken out, rinsed with deionized water and stored in absolute ethanol for dehydration treatment to obtain a delignified veneer template;

[0036] (4): Weigh 0.1g of alkali lig...

Embodiment 2

[0041] (1): Select a poplar veneer sample with a size of 20mm*20mm*1.5mm, and dry it at 85°C for 12 hours to a dry state. The density of the veneer sample after drying is 0.087g / cm 3 spare;

[0042] (2): Mix 20g of sodium hypochlorite and 500ml of distilled water and stir evenly. Use glacial acetic acid to adjust the pH of the mixed solution to 4.6 to obtain a delignification aqueous solution. Soak 1.044g of veneer samples dried in step (1) in the delignification In the plain aqueous solution, heat in a water bath at 85°C for 8 hours for delignification treatment, until the veneer sample is white;

[0043] (3): The veneer sample that has been delignified in step (2) is taken out, rinsed with deionized water and stored in absolute ethanol for dehydration treatment to obtain a delignified veneer template;

[0044](4): Weigh 0.1g of alkali lignin, 0.3g of o-phenylenediamine and 0.3g of terephthalic acid, add them to 10ml of absolute ethanol, mix them evenly, and place them in a ...

Embodiment 3

[0049] (1): Select a poplar veneer sample with a size of 20mm*20mm*1.5mm, and dry it at 90°C for 12 hours to a dry state. The density of the veneer sample after drying is 0.087g / cm 3 spare;

[0050] (2): Mix 20g of sodium hypochlorite and 500ml of distilled water and stir evenly. Use glacial acetic acid to adjust the pH of the mixed solution to 4.6 to obtain a delignification aqueous solution. Soak 1.044g of veneer samples dried in step (1) in the delignification In the plain aqueous solution, heat in a water bath at 85°C for 8 hours for delignification treatment, until the veneer sample is white;

[0051] (3): The veneer sample that has been delignified in step (2) is taken out, rinsed with deionized water and stored in absolute ethanol for dehydration treatment to obtain a delignified veneer template;

[0052] (4): Weigh 0.1g of alkali lignin and 0.3g of p-phenylenediamine into 10ml of sulfuric acid solution with a concentration of 40wt% and mix evenly, and place them in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air dry density | aaaaa | aaaaa |

| Absolute dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com