Method for improving strength of activated alumina balls

A technology of activated alumina and aluminum hydroxide, applied in the field of activated alumina balls, can solve the problems of easily broken and pulverized activated alumina balls, insufficient strength of activated alumina balls, insufficient strength of activated alumina balls, etc. Insufficient strength, improved shedding, and effect of reducing wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

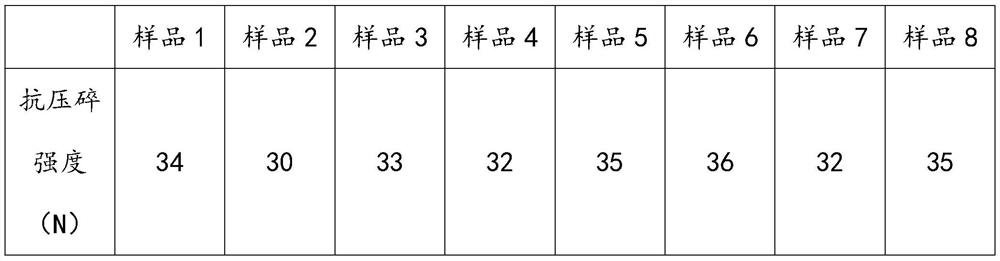

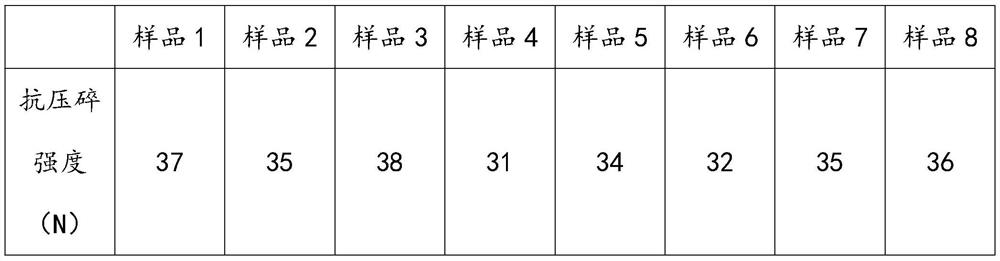

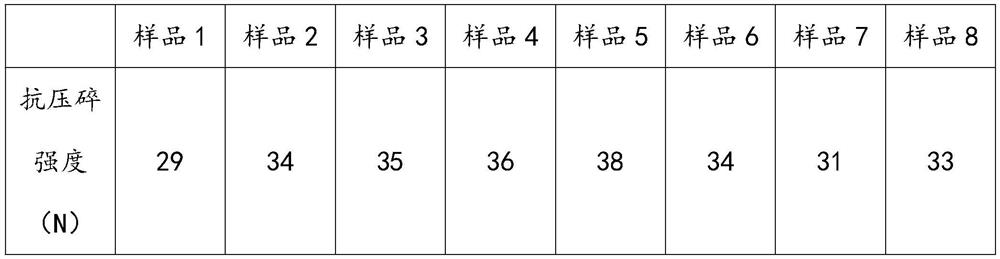

Examples

Embodiment 1

[0045] The invention provides a technical solution: a method for improving the strength of activated alumina balls, comprising the following steps:

[0046] S1. Use a high-speed ball forming device to mix aluminum hydroxide powder, binder, bicarbonate, pseudoboehmite, cellulose forming agent and water to make activated alumina balls with a diameter of 1-3mm;

[0047] The obtaining method of aluminum hydroxide powder comprises the following steps:

[0048] S11, reacting sodium metaaluminate solution and 38% nitric acid solution to obtain aluminum hydroxide precipitate, the pH of which is 4-7 during precipitation, and the temperature is 0-10°C;

[0049] S12. Heating the aluminum hydroxide precipitate at 40-60°C for 3 hours, then keeping at 65-85°C for 3 hours, and finally drying at 90-110°C;

[0050] S13. Take out the dried aluminum hydroxide and pulverize it, and sieve the powder smaller than 200 meshes as the aluminum hydroxide powder for preparing activated alumina balls;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com