Al-Al2O3 sliding plate brick added with titanium nitride coated mullite and production method of Al-Al2O3 sliding plate brick

A sliding brick and titanium nitride technology, which is applied in the field of functional refractory materials, can solve problems such as not meeting clean steel smelting requirements, destroying product structure, and affecting product life, achieving good thermal conductivity, chemical stability, and good corrosion resistance , Improve the effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

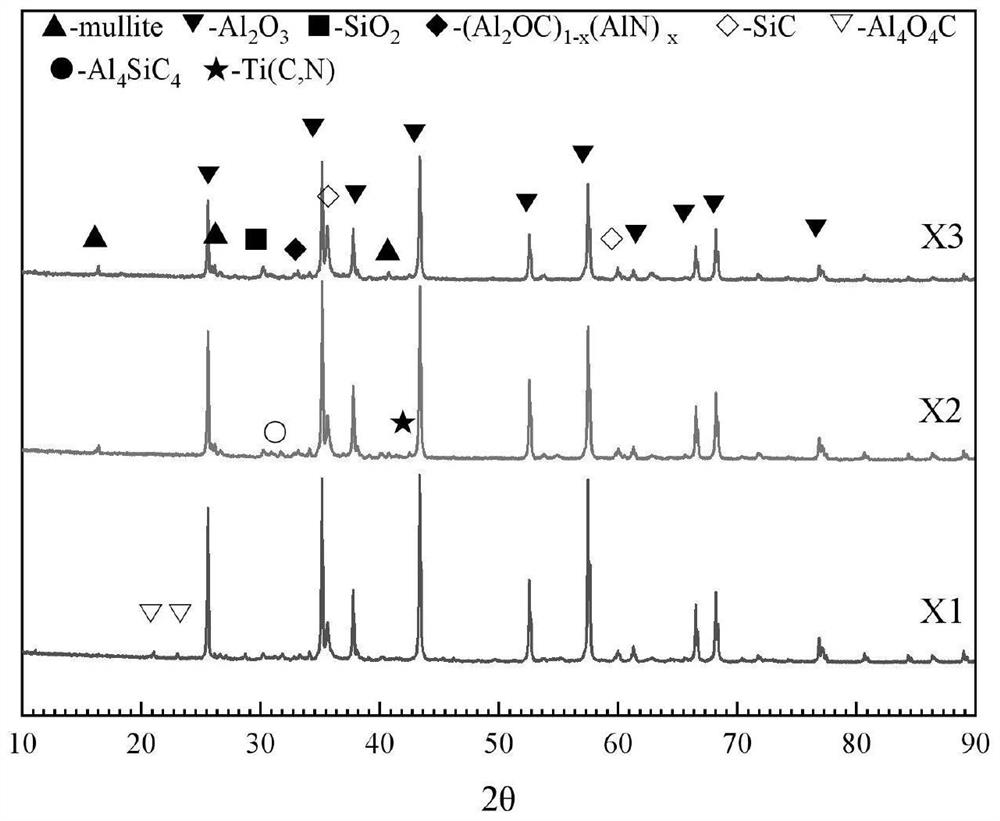

Embodiment 1

[0033] A kind of Al-Al with adding titanium nitride to wrap mullite 2 o 3 Skateboard bricks, by weight percentage, the raw materials are: 74% tabular alumina, 3% CL370, 3% RG4000, 10% fused mullite, 10% metal aluminum powder, plus the total amount of the above raw materials 3% thermosetting phenolic resin.

[0034]The particle size range of tabular corundum is: 1mm<particle size 1≤2mm, 0.5mm<particle size 2≤1mm, 0.044mm<particle size 3≤0.5mm, 0<particle size 4≤0.044mm, and the weight ratio of different particle sizes is: particle size 1: Granularity 2: Granularity 3: Granularity 4 = 20:22:20:12.

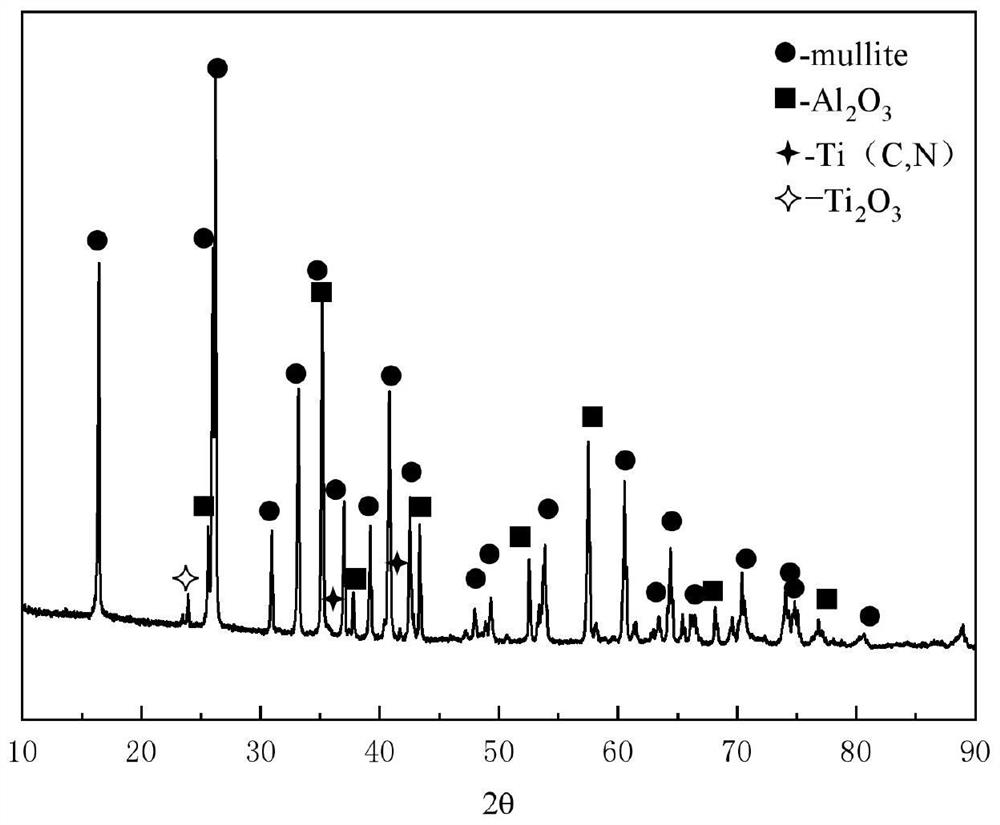

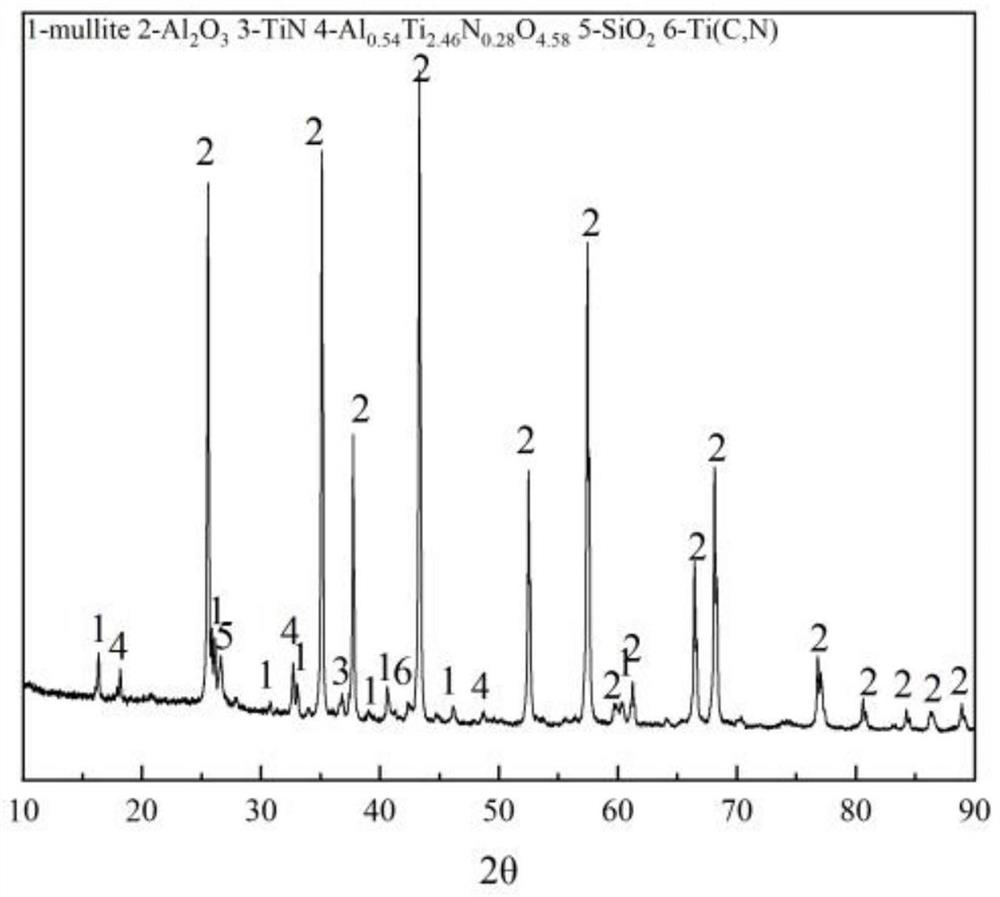

[0035] The particle size range of fused mullite is: 1 ≤ particle size ≤ 2mm; fused mullite is a Ti-containing material prepared by using low-grade or waste bauxite through high-temperature electric melting at 2000°C. 2 o 3 Fused mullite, by weight percentage, the main component weight content of fused mullite is Al 2 o 3 : 70-75%, SiO 2 : 10-15%, TiO 2 : 5-8%.

[0036] The p...

Embodiment 2

[0048] A kind of Al-Al with adding titanium nitride to wrap mullite 2 o 3 Skateboard tiles, by weight percentage, the raw materials are: 64% tabular alumina, 3% CL370, 3% RG4000, 20% fused mullite, 10% metal aluminum powder, plus the total amount of the above raw materials 3.5% thermosetting phenolic resin.

[0049] The particle size range of tabular corundum is: 1mm<particle size 1≤2mm, 0.5mm<particle size 2≤1mm, 0.044mm<particle size 3≤0.5mm, 0<particle size 4≤0.044mm, and the weight ratio of different particle sizes is: particle size 1: Granularity 2: Granularity 3: Granularity 4 = 10:22:20:12.

[0050] The particle size range of fused mullite is: 1 ≤ particle size ≤ 2mm; fused mullite is a Ti-containing material prepared by using low-grade or waste bauxite through high-temperature electric melting at 2000°C. 2 o 3 Fused mullite, by weight percentage, the main component weight content of fused mullite is Al 2 o 3 : 70-75%, SiO 2 : 10-15%, TiO 2 : 5-8%.

[0051] The...

Embodiment 3

[0053] A kind of Al-Al with adding titanium nitride to wrap mullite 2 o 3 Skateboard tiles, by weight percentage, the raw materials are: 54% tabular alumina, 3% CL370, 3% RG4000, 30% fused mullite, 10% metal aluminum powder, plus the total amount of the above raw materials 4% thermosetting phenolic resin.

[0054] The particle size range of tabular corundum is: 1mm

[0055] The particle size range of fused mullite is: 1 ≤ particle size ≤ 2mm; fused mullite is a Ti-containing material prepared by using low-grade or waste bauxite through high-temperature electric melting at 2000°C. 2 o 3 Fused mullite, by weight percentage, the main component weight content of fused mullite is Al 2 o 3 : 70-75%, SiO 2 : 10-15%, TiO 2 : 5-8%.

[0056] The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com