Purification method for improving hydrolysis resistance of phosphate fire-resistant oil

A technology of hydrolysis resistance and phosphate ester, which is applied in the field of fuel oil resistance, can solve the problems of complex process, high cost, and poor effect, and achieve the effect of simple and convenient operation and improved hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

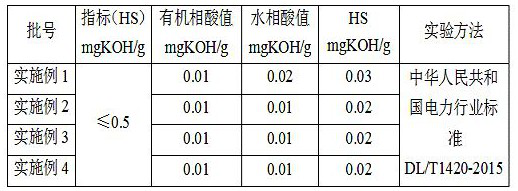

Examples

Embodiment 1

[0023] A purification method for improving the hydrolysis resistance of phosphate-resistant fuel oil, comprising the following steps:

[0024] Step 1, add phosphoric acid ester crude product 3kg in washing kettle;

[0025] Step 2. Add 2kg of solvent to the washing kettle, the solvent is toluene and cyclohexane, toluene:cyclohexane=1:1;

[0026] Step 3, after stirring and dissolving the crude phosphate ester and solvent, add 2 kg of 3% alkaline water for alkaline washing;

[0027] Step 4: Warm up to 50-55°C, after fully stirring, drive the material into the layered tank through a centrifugal pump to stand still, separate by gravity sedimentation, drain the water layer, and put the precipitated material into the washing tank;

[0028] Step 5, repeat step 3 and step 4 to carry out the second alkali washing;

[0029] Step 6. Add 2kg of deionized water to the material in the washing tank after the precipitation in step 5 for the third washing, and then repeat step 4 for layered p...

Embodiment 2

[0033] A purification method for improving the hydrolysis resistance of phosphate-resistant fuel oil, comprising the following steps:

[0034] Step 1, add phosphoric acid ester crude product 3kg in washing kettle;

[0035] Step 2: Add 1.6kg of solvent into the washing kettle, the solvent is petroleum ether at 60-90°C;

[0036] Step 3, after stirring and dissolving the crude phosphate ester and solvent, add 2 kg of 2% alkaline water for alkaline washing;

[0037] Step 4: Heat up to 40-45°C, and after fully stirring, put the material into the layered tank through a centrifugal pump to stand still, separate by gravity sedimentation, drain the water layer, and put the precipitated material into the washing tank;

[0038] Step 5, repeat step 3 and step 4 to carry out the second alkali washing;

[0039] Step 6. Add 2kg of deionized water to the material in the washing tank after the precipitation in step 5 for the third washing, and then repeat step 4 for layered precipitation;

...

Embodiment 3

[0043] A purification method for improving the hydrolysis resistance of phosphate-resistant fuel oil, comprising the following steps:

[0044] Step 1, add phosphoric acid ester crude product 3kg in washing kettle;

[0045] Step 2, add 2.1kg solvent in the washing tank, the solvent is xylene;

[0046] Step 3, adding 1.8kg of 4% alkaline water after stirring and dissolving the crude phosphate ester and solvent for alkaline washing;

[0047] Step 4: Heat up to 60-65°C, after fully stirring, put the material into the layered tank through the centrifugal pump to rest, separate by gravity sedimentation, drain the water layer, and put the precipitated material into the washing tank;

[0048] Step 5, repeat step 3 and step 4 to carry out the second alkali washing;

[0049] Step 6. Add 1.8 kg of deionized water to the material in the washing tank after the precipitation in step 5 for the third washing, and then repeat step 4 for layered precipitation;

[0050] Step 7, sending the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| autoignition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com