Water-based metal cutting fluid and preparation method thereof

A metal-based and cutting fluid technology, which is applied in the field of water-based metal cutting fluid and its preparation, can solve the problems of poor stability and short service life, and achieve the effects of good resistance to hard water, difficult saponification, improved performance and use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Another embodiment of the present invention discloses a method for preparing a water-based metal cutting fluid, comprising the following steps:

[0040] A) Mix isovaleric acid and drying oil, add catalyst X, stir, and heat reaction at 150-250°C to obtain light yellow mixed liquid;

[0041] B) Mix the light yellow mixed solution with polyethylene glycol 400, add catalyst Y, stir, and heat at 150-250°C for reaction to obtain partially acidolyzed dry oil polyethylene glycol ester;

[0042] C) Mix and disperse partially acid-hydrolyzed drying oil polyethylene glycol ester, mineral oil, phosphate ester rust inhibitor, polyether, nonionic surfactant and water to obtain a water-based metal cutting fluid.

Embodiment 1

[0045] This example discloses a method for preparing partially acidolyzed drying oil polyethylene glycol ester, which is prepared from isovaleric acid, linseed oil and polyethylene glycol 400. The preparation method includes the following steps:

[0046] A) Mix isovaleric acid and dry oil (linseed oil is used in the present invention) in a mass ratio of 1:4, add catalyst X, and catalyst X is selected from isopropyl titanate with a mass ratio of 2:1 and ultrafine The processed yellow dandelion was stirred and heated to 180°C for reaction (protected by nitrogen gas) for 180 minutes to obtain a light yellow mixed solution;

[0047] B) Mix a light yellow mixed solution and polyethylene glycol 400 at a mass ratio of 1:3, add catalyst Y, the catalyst Y is selected from benzenesulfonic acid, stir and heat to 250°C for reaction (protected by nitrogen) for 360 minutes , At the same time remove a small amount of water generated, to obtain partially acid-hydrolyzed dry oil polyethylene g...

Embodiment 2

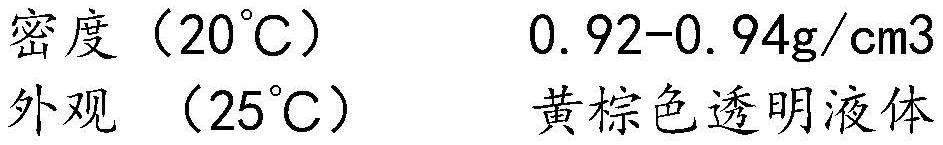

[0049] This example provides an application example in which the partially acidified dry oil polyethylene glycol ester prepared in Example 1 is applied to the preparation of metalworking cutting fluid. The experimental formula is as follows:

[0050]

[0051] Process: Add 1 / 3 water into the beaker, slowly add partially acid-decomposed dry oil polyethylene glycol ester, polyether, 6501 and phosphate ester rust inhibitor in turn, stir evenly, then increase the stirring speed and slowly Add mineral oil for emulsification, and finally add the remaining 2 / 3 water to dilute, and obtain metal processing cutting fluid S1 after standing still.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com