Ferrite particles, electrophotographic developer carrier core material, electrophotographic developer carrier, and electrophotographic developer

An electrophotography and ferrite technology, applied in the direction of developer, iron oxide/hydroxide, circuit, etc., can solve the problems of easy white spots, carrier scattering, etc., and achieve the effect of inhibiting carrier scattering and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0168] (1) Ferrite particles

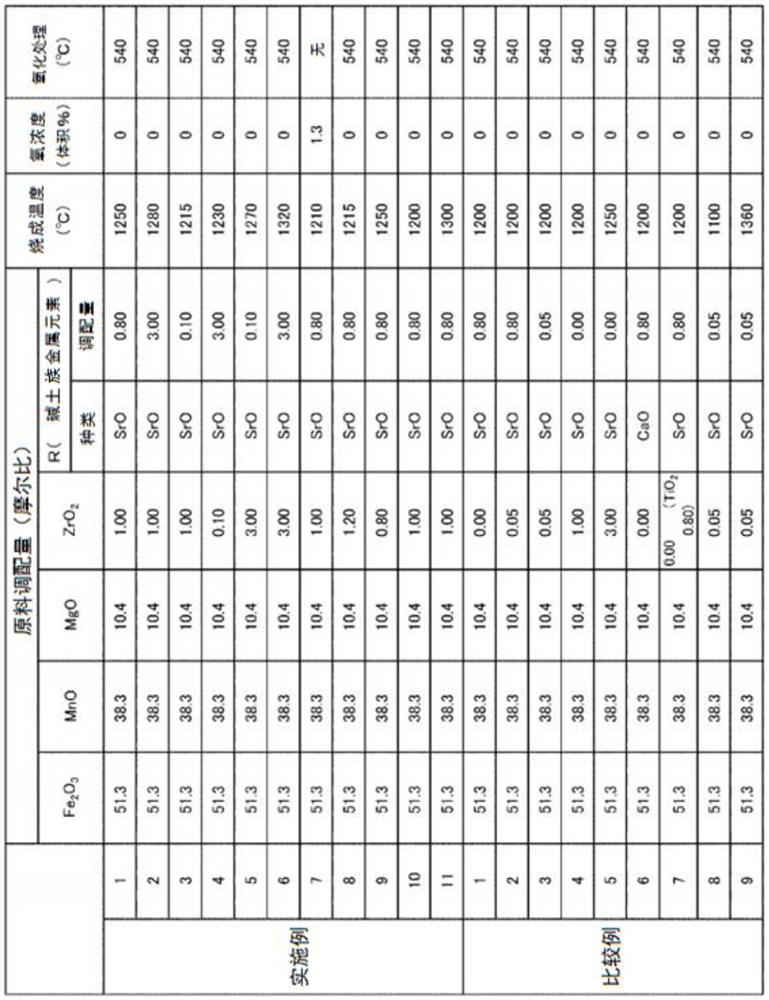

[0169] In Example 1, it was produced as follows so that from (MnO)x(MgO)y(Fe 2 o 3 ) The crystal phase composition composed of spinel crystals represented by the chemical formula of z as the main component contains SrZrO 3 The chemical formula (R = Sr) represented by the perovskite crystal phase composition of ferrite particles composed of crystal phase. First, the MnO raw material, the MgO raw material, and the Fe 2 o 3 Raw materials, in terms of molar ratio, MnO conversion: 38.3, MgO conversion: 10.4, Fe 2 o 3 : 51.3. In addition, the SrO raw material was weighed so that it would be SrO: 0.8 with respect to the main component raw material: 100 in molar ratio. Here, trimanganese tetraoxide was used as the MnO raw material, magnesium oxide was used as the MgO raw material, and Fe 2 o 3 Iron oxide was used as the raw material, and strontium carbonate was used as the SrO raw material.

[0170] Then, the weighed raw material was pulverized...

Embodiment 2

[0181] In this example, except for the point where the SrO raw material is weighed so that the molar ratio is SrO: 3.00 relative to the above-mentioned main component raw material: 100, and the firing temperature (holding temperature) at the time of main firing is set to 1280°C Ferrite particles of Example 2 were produced in the same manner as in Example 1 except for the points above. Table 1 shows the main production conditions of Example 2. Moreover, except having used this ferrite particle as a core material, it carried out similarly to Example 1, and produced the carrier for electrophotographic developers, and produced the electrophotographic developer using this carrier for electrophotographic developers.

Embodiment 3

[0183] In this example, except for the point where the SrO raw material is weighed so that the molar ratio is SrO: 0.10 with respect to the above-mentioned main component raw material: 100, and the firing temperature (holding temperature) at the time of main firing is set to 1215°C Ferrite particles of Example 3 were produced in the same manner as in Example 1 except for the above points. Table 1 shows the main production conditions of Example 3. Moreover, except having used this ferrite particle as a core material, it carried out similarly to Example 1, and produced the carrier for electrophotographic developers, and produced the electrophotographic developer using this carrier for electrophotographic developers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com