N-vinyl pyrrolidone purification system and method

A vinylpyrrolidone and purification method technology, applied in the field of N-vinylpyrrolidone preparation, can solve the problems of many reaction steps, environmental pollution, low production efficiency, etc., reduce the chance of self-polymerization of materials, reduce production costs, The effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

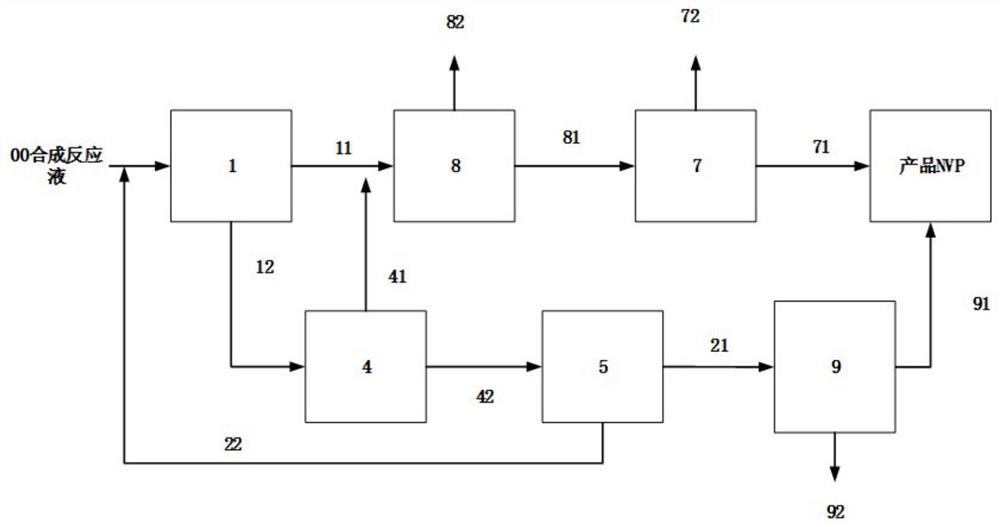

[0107] figure 1 It is a schematic diagram of the NVP refining system and process flow according to Embodiment 1 of the present invention.

[0108] Such as figure 1 As shown, a kind of N-vinylpyrrolidone refining system comprises: the first rectifying unit 1, the first crystallization system 8 and the third rectifying unit 7 connected in series through the pipeline, the second rectifying unit 2 and the second rectifying unit connected in series The second crystallization system 9, and the NVP storage tank. Wherein, the first rectification unit 1 receives the synthetic reaction solution 00 containing NVP, carries out rectification treatment and outputs the first distillate 11 and the first still out 12, and the first crystallization system 8 receives the first distillate 11, carries out crystallization purification and outputs The first crystallization solution 81 and the first mother liquor 82, the third rectification unit 7 receives the first crystallization solution 81 and ...

Embodiment approach 2

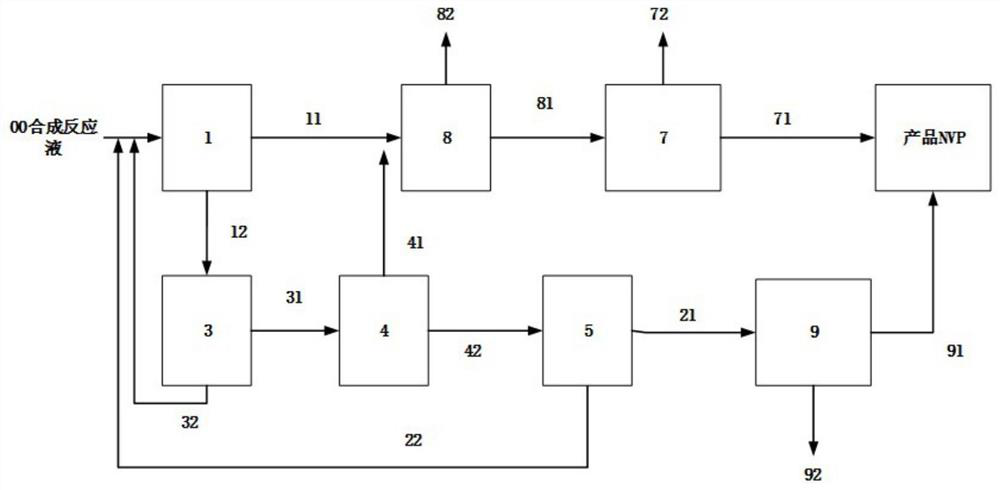

[0117] figure 2 Schematic diagram of the NVP purification system and process flow according to Embodiment 2. The synthetic reaction solution 00 of NVP is prepared by the acetylene synthesis method. After gas-liquid separation, the synthetic reaction solution 00 comprises 30-55% (wt%) of NVP, 45-70% (wt%) of a-p, and 00 of the synthetic reaction solution. 960 liters / hour enters the first rectification unit 1 to carry out primary NVP purification (ie primary rectification purification). It is different from Embodiment 1 mainly in the following aspects:

[0118] Such as figure 2 As shown, the second rectification unit 2 of the NVP refining system includes two packed columns connected in sequence, that is, the fourth rectification tower 4 and the fifth rectification tower 5, and the fourth rectification tower 4 receives the first rectification unit 1 The first still goes out 12, carries out distillation purification, and outputs the 4th still and goes out 41 and the 4th still g...

Embodiment approach 3

[0122] image 3 Schematic diagram of the NVP purification system and process flow according to Embodiment 3. The synthetic reaction solution 00 of NVP is prepared by the acetylene synthesis method. After gas-liquid separation, the synthetic reaction solution 00 comprises 30-55% (wt%) of NVP, 45-70% (wt%) of a-p, and 00 of the synthetic reaction solution. 960 liters / hour enters the first rectification unit 1 to carry out primary NVP purification (ie primary rectification purification). It is different from Embodiment 2 mainly in the following aspects:

[0123] Such as image 3 As shown, the second rectification unit 2 of the NVP refining system also includes a third rectification tower 3, the third rectification tower 3 is arranged on the front end of the fourth rectification tower 4 and connected in series with it, and the third rectification tower 3 receives from The first still of the first rectification unit 1 goes out 12 and outputs the third still and goes out 31 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com