An ultra-low oxygen water content atmosphere control device for metal additive manufacturing

A metal additive and control device technology, applied in the field of 3D printing, can solve the problems of low air purification efficiency, increase manufacturing cost, increase powder oxygen and hydrogen content, etc., to achieve the effect of improving purification efficiency, prolonging validity period and reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

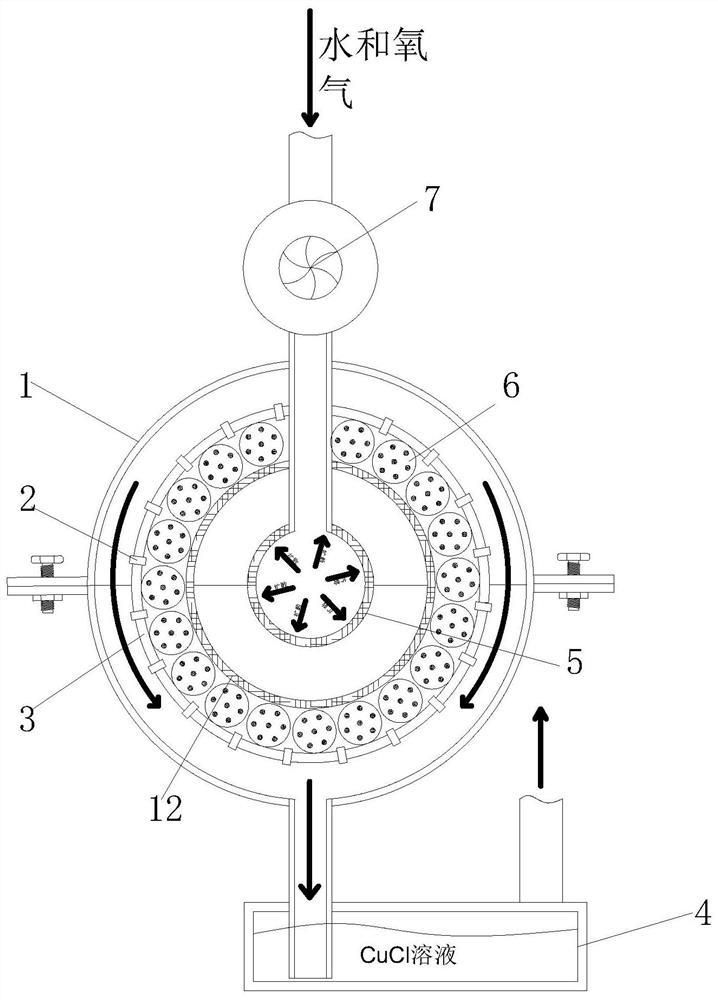

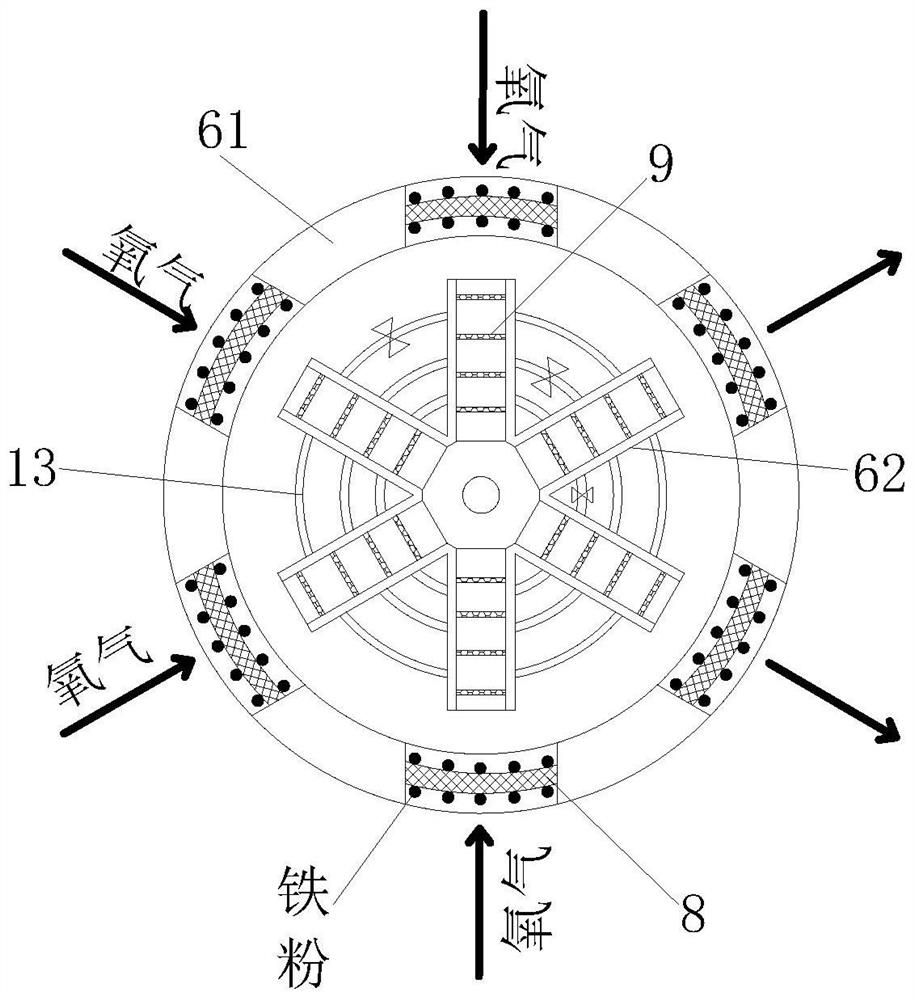

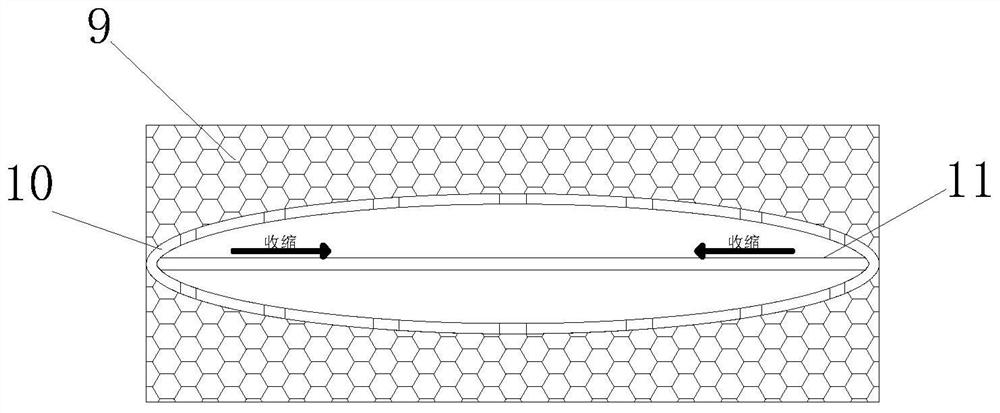

[0042] see figure 1, an ultra-low oxygen water content atmosphere control device for metal additive manufacturing, including a control box 1, the inside of the control box 1 is provided with a sealed shell 3, the inside of the sealed shell 3 is provided with an isolation cover 12, and the isolation cover 12 An inner tank 5 is arranged inside, and one end of the control box 1 is connected with an air intake pipe, and one end of the air intake pipe passes through the control box 1, the sealing shell 3 and the isolation cover 12 and is connected to the side wall of the control box 1, the sealing shell 3 and the isolation cover 12 It is fixedly connected, and at the same time, this end is fixedly connected with the liner 5, the other end of the air intake pipe is connected with a circulation fan 7, the other end of the control box 1 is connected with an air outlet pipe, one end of the air outlet pipe is fixedly connected with the purification box 4, and the air outlet pipe of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com