Catalyst and method for preparing biodiesel by using catalyst

A biodiesel and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult catalyst recovery, high esterification reaction temperature, increased economic cost, etc., to achieve good catalytic performance Activity and application value, excellent recycling ability, and the effect of reducing resource recovery and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

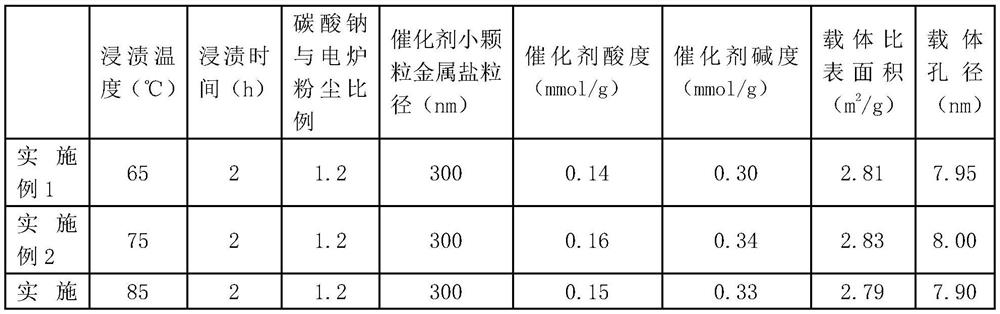

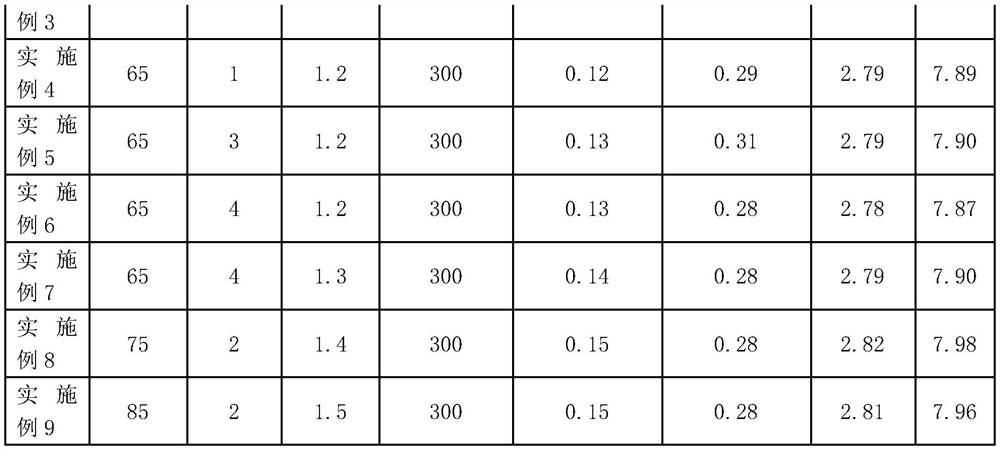

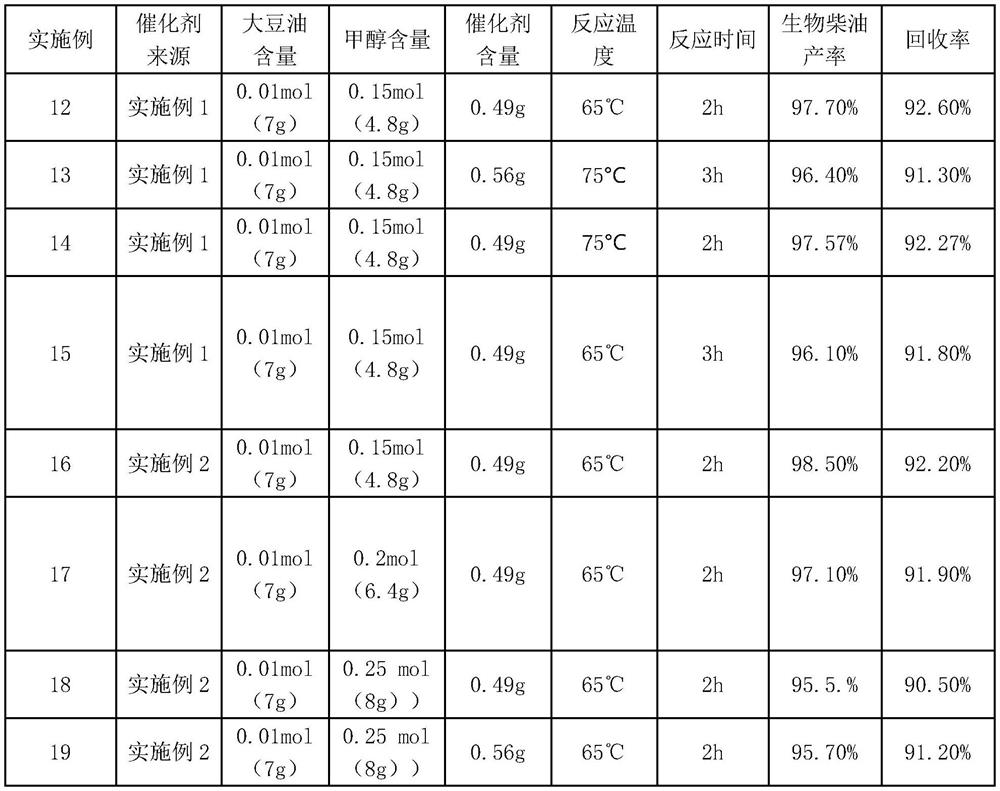

[0034] Take Fe: 54.84%, Mg: 0.55%, Zn: 1.42%, Ca: 1.65%, Mn: 1.08%, Al: 0.25%, Na: 0.25% of the electric furnace dust and use a ball mill to grind the dust through a 200-mesh sieve After sieving, the dust was dried in an oven at 105°C for 5 hours to obtain electric furnace dust raw materials with uniform particles after drying. After drying, the raw material of electric furnace dust with uniform particles was impregnated with sodium carbonate and placed in an oil bath for magnetic stirring, setting the appropriate temperature and time for impregnation, and the obtained sample was dried and passed through a 200-mesh sieve to obtain a sodium-electric furnace dust catalyst. Wherein the parameter and effect of embodiment 1-9 are as shown in table 1.

[0035] Parameters and effects of table 1 embodiment 1-9

[0036]

[0037]

[0038] After measurement, the particle diameter of the small-particle metal salt of the electric furnace dust raw material is about 200nm; the particl...

Embodiment 10

[0040] Repeat Example 2 with the following differences: the composition of the electric furnace dust is Fe: 54.54%, Mg: 0.50%, Zn: 1.38%, Ca: 1.60%, Mn: 1.00%, Al: 0.23%, Na: 0.24%. The particle size of the obtained catalyst small-particle metal salt is about 300nm, the acidity of the catalyst is determined to be 0.15mmol / g, the basicity is 0.33mmol / g, and the specific surface area of the carrier is 2.80m 2 / g, the pore size of the carrier is 7.92nm.

Embodiment 11

[0042]Repeat Example 2 with the following differences: the composition of the electric furnace dust is Fe: 54.50%, Mg: 0.48%, Zn: 1.34%, Ca: 1.57%, Mn: 0.98%, Al: 0.21%, Na: 0.23%. The particle size of the obtained catalyst small-particle metal salt is about 300nm, the acidity of the catalyst is determined to be 0.13mmol / g, the basicity is 0.31mmol / g, and the specific surface area of the carrier is 2.78m 2 / g, the carrier pore size is 7.86nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com