Corn product processing device and method

A processing device and technology for corn, applied in chemical instruments and methods, cleaning methods using tools, combined devices, etc., can solve the problems of unclean de-baking, easy cleaning and uncleanness, increase production costs, etc., and achieve improved efficiency and cleanliness. speed, fast and efficient cleaning, and increase the effect of axial friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

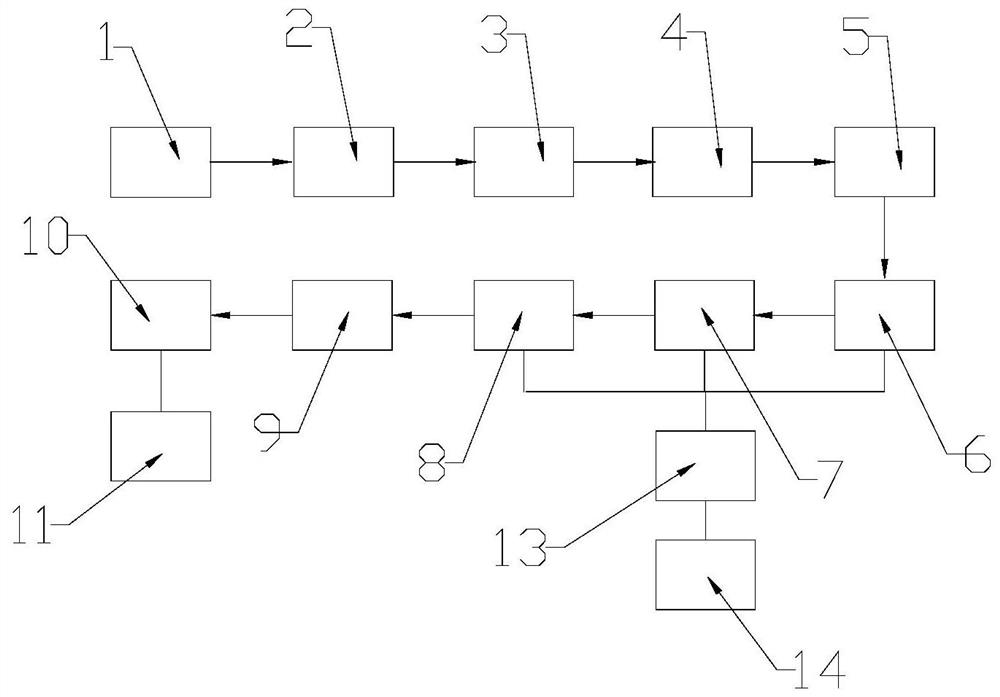

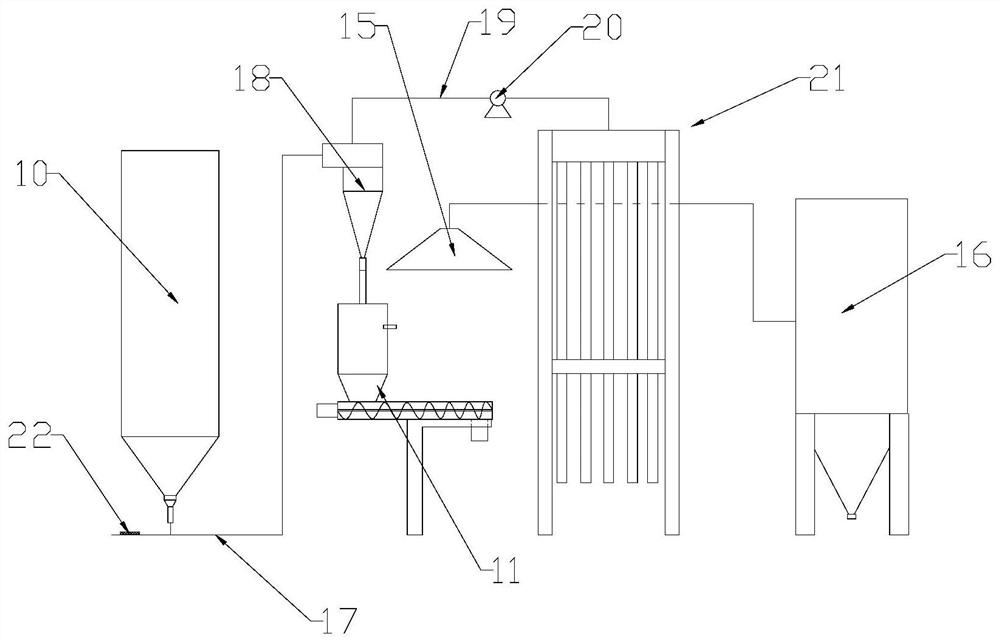

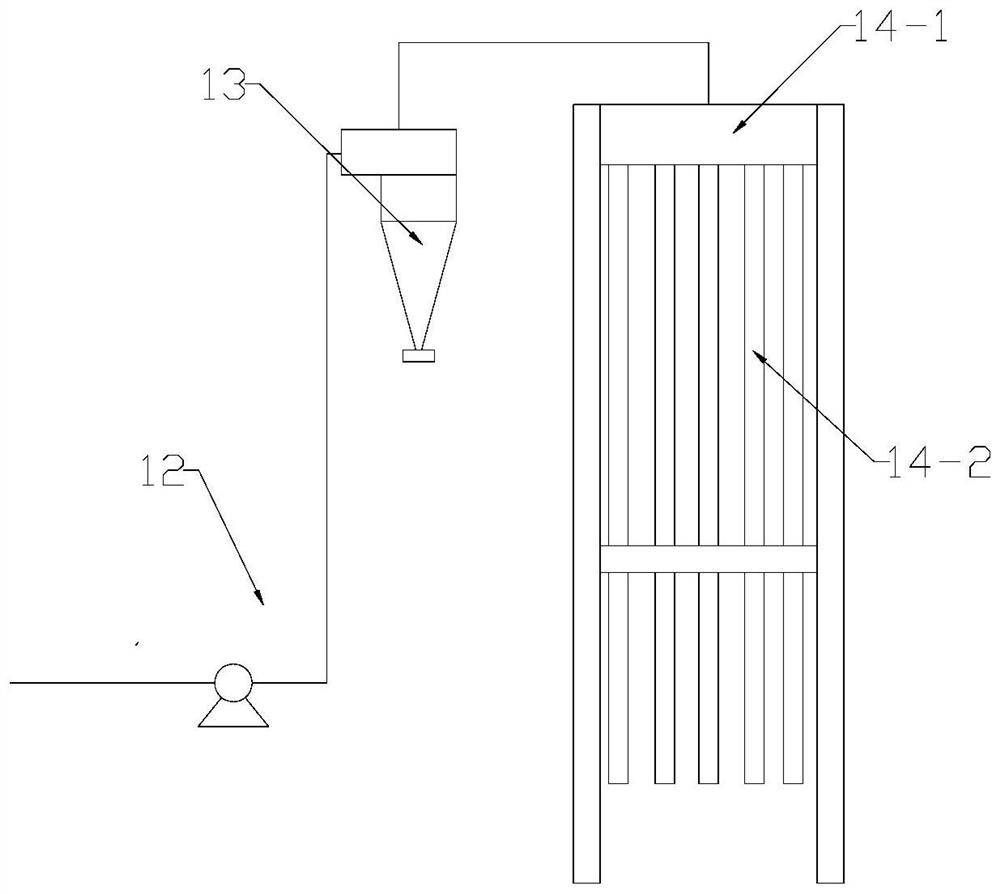

[0044] A corn processing device, comprising a first magnetic separator 1, a vibrating screen 2, a stone remover 3, a cleaning machine 4, a grain moistening machine 5, a peeling crusher 6, a milling machine 7, and a double-chamber flat screen connected in sequence 8. The second magnetic separator 9, the temporary storage tank 10 and the packaging machine 11, the peeling crusher 6, the mill 7 and the double-compartment flat screen 8 are all connected to the first cyclone collector 13 through the first pneumatic conveying mechanism 12 , the air outlet of the first cyclone collector 13 is connected to the first bag filter 14, the first bag filter 14 includes a gas collecting box 14-1, and the lower end of the gas collecting box 14-1 is provided with a plurality of gas collecting ports, collecting A filter bag 14-2 is provided at the air port, and an openable powder recovery port is provided at the lower end of the filter bag 14-2, and the air inlet of the gas collecting box 14-1 is...

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, the difference is that the cleaning machine 4 includes a casing 4-1, and the casing 4-1 is sequentially provided with a first conveying cleaning mechanism, a friction cleaning mechanism and a second cleaning mechanism along the conveying direction of the corn. The second conveying and cleaning mechanism, a material guide assembly is arranged between the discharge end of the first cleaning mechanism and the feed end of the friction cleaning mechanism, and the discharge end of the friction cleaning mechanism is located above the feed end of the second conveying and cleaning mechanism.

[0048] Both the first cleaning mechanism and the second cleaning mechanism include a transmission conveying net 4-2, and a driving roller and a driven roller are connected through bearings in the casing 4-1, and the conveying net 4-2 is set on the driving roller and the driven roller. Outside, driving roller is driven by reduction motor...

Embodiment 3

[0054] This embodiment is basically the same as Embodiment 1 or 2, except that the peeling crusher 6 includes an outer cylinder, and the outer cylinder is provided with a rotating shaft 6-1, and the end of the rotating shaft 6-1 and the outer cylinder rotates through a bearing Connected, the rotating shaft 6-1 and the drive motor are driven by a gear belt. Outer cylinder comprises intermediate cylinder 6-2, and the feed end of intermediate cylinder 6-2 is fixed with feed cylinder 6-3, and discharge end is fixed with discharge cylinder 6-4, and the rotating shaft 6 in feed cylinder 6-3 -1 is fixed with feeding screw blade 6-5, on the rotating shaft 6-1 in the middle cylinder 6-2, is fixed with peeling sand roller 6-6, on the rotating shaft 6-1 of discharging cylinder 6-4, is fixed with The discharge spiral blade 6-7, the outer side of the peeling sand roller 6-6 is equipped with a reciprocating screen cylinder 6-8, by setting the reciprocating screen cylinder 6-8, on the one ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com