Wear-resistant, flame-retardant and moisture-absorption-resistant acrylic plate

An acrylic board and moisture-absorption-resistant technology, which is applied in the field of acrylic board processing, can solve the problems of general surface wear resistance, lack of attention to one thing and loss of another, and the need to improve moisture absorption performance, so as to reduce water absorption rate, prolong service life, and improve fire-proof and flame-retardant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

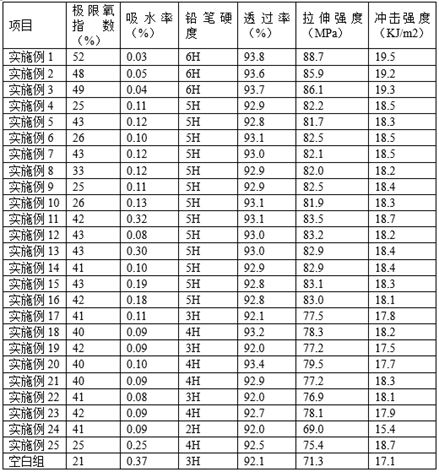

Examples

Embodiment 1

[0029] A wear-resistant, flame-retardant, and moisture-resistant acrylic sheet, the raw materials, calculated in parts by weight, include 140 parts of new PMMA acrylic materials, 2 parts of auxiliary agents, 2 parts of flame retardant components, 1.5 parts of moisture-resistant components, and 2 parts of wear-resistant and anti-reflection components. share;

[0030] The specific preparation method is (1), high temperature melting: put the new PMMA acrylic material in a high temperature kneader in proportion, heat it to 185 °C at 12 °C / min, keep the constant temperature for 40 minutes, naturally drop to 100 °C, keep the temperature for 25 minutes, and then restart Heating to 185°C at a heating rate of 5°C / min, and stirring at a constant temperature of 1500r / min for 50min; (2) Preparation of the mixture: adding additives, flame-retardant components, moisture-resistant components, wear-resistant and anti-reflection components respectively (3), pouring and molding: transfer the mi...

Embodiment 2

[0046] A wear-resistant, flame-retardant and moisture-resistant acrylic sheet, the raw materials, calculated in parts by weight, include 120 parts of new PMMA acrylic materials, 1 part of auxiliary agents, 3 parts of flame retardant components, 2 parts of moisture-absorbing components, and 3 parts of wear-resistant and anti-reflective components. share;

[0047] The specific preparation method is (1), high temperature melting: the new PMMA acrylic material is placed in a high temperature kneader in proportion, heated to 170°C at 9°C / min, maintained at a constant temperature for 30min, naturally lowered to 90°C, maintained for 20min, and then re-heated. Heating to 170°C at a heating rate of 4°C / min, stirring at a constant temperature of 10000r / min for 40min; (2) Preparation of the mixture: adding additives, flame retardant components, moisture-resistant components, wear-resistant and anti-reflection components respectively (3), pouring and molding: transfer the mixture to the p...

Embodiment 3

[0058] A wear-resistant, flame-retardant, and moisture-resistant acrylic sheet, the raw materials, calculated in parts by weight, include 160 parts of PMMA acrylic new materials, 3 parts of auxiliary agents, 1 part of flame retardant components, 1 part of moisture-resistant components, and 1 part of wear-resistant and anti-reflective components. share;

[0059] The specific preparation method is (1), high temperature melting: the new PMMA acrylic material is placed in a high temperature kneader in proportion, heated to 200°C at 16°C / min, maintained at a constant temperature for 50min, naturally reduced to 110°C, kept at a temperature for 30min, and then restarted. Heating to 200°C at a heating rate of 6°C / min, stirring at a constant temperature of 2000r / min for 60min; (2) Mixing preparation: adding additives, flame-retardant components, moisture-resistant components, wear-resistant and anti-reflection components respectively (3), pouring and molding: transfer the mixture to po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com