Thermal insulation structural adhesive for new energy power battery and manufacturing method of thermal insulation structural adhesive

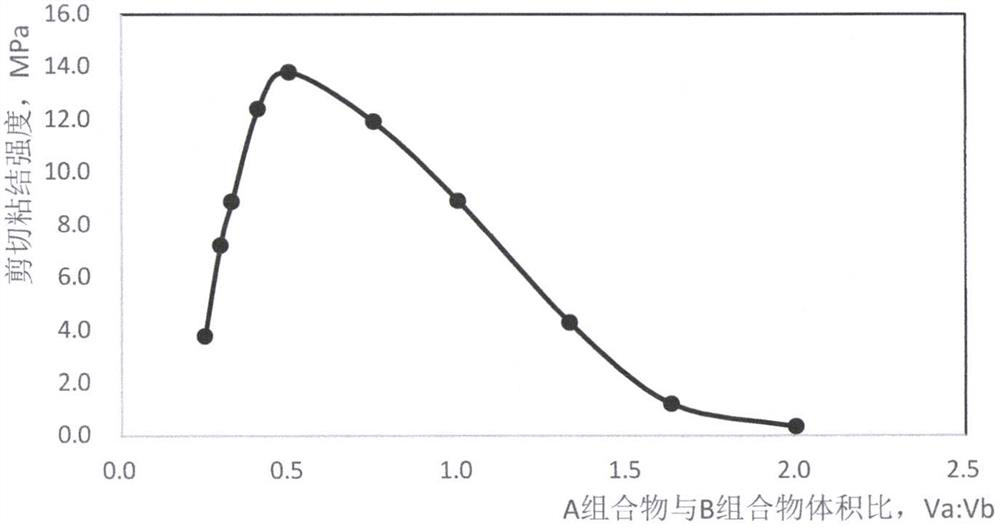

A technology for power batteries and structural adhesives, applied in secondary batteries, circuits, adhesives, etc., can solve the problems of low shear bond strength, reduced safety, and insufficient structural strength of CTP battery packs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 47

[0122] A composition, block polymerization process of telechelic carboxyl compound base material——

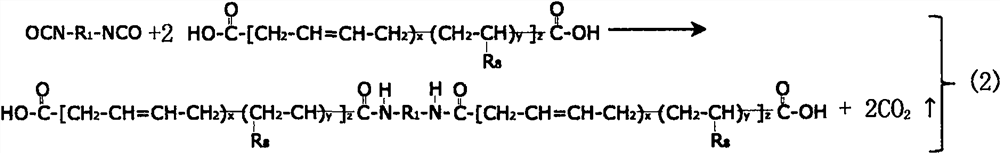

[0123] In reactor A, add any one of isocyanate or epoxy resin or epoxy polyalkylsiloxane, telechelic carboxypolybutadiene according to the mass ratio in Table 1, start the stirring device to make isocyanate or epoxy Base resin or epoxy-based polyalkylsiloxane and telechelic carboxypolybutadiene are mixed uniformly; when the added material is isocyanate and telechelic carboxypolybutadiene, the temperature of the material is controlled at (25-45 )°C, and the holding time is 6h, the reaction product is obtained according to the chemical structural formula (2); when the added material is epoxy resin and telechelic carboxy polybutadiene, the temperature of the material is controlled between (75~135)°C Between, and holding time 4.0h, reaction product is gained according to chemical structural formula (3); When adding material is epoxy polyalkyl siloxane and telechelic carboxyl polybu...

Embodiment 48

[0131] In a reactor A with high-speed stirring and high-shear dispersing device, according to Table 1, first add at least one of the telechelic carboxyl compound and / or telechelic amino compound base material, coupling agent and / or Or modifiers, curing accelerators, heat insulating powders, flame retardant ingredients;

[0132] In a B reactor with a high-speed stirring and high-shear dispersing device, according to Table 2, first add at least one of the telechelic isocyanate-based compound and / or the telechelic epoxy-based compound according to step (1), Coupling agent and / or modifier, curing accelerator, heat insulating powder, flame retardant components;

[0133] In reactor A and reactor B respectively, according to the average particle size of the powder D 50 The specifications are divided into three batches of "fine→medium→coarse", and the thinnest D is added first 50 Specification of powder → sub-fine D 50 Specification powder→coarse D 50 Specifications of powder; eve...

Embodiment 49

[0135] Start the vacuum pump at the same time or at the later stage of step (2), slowly reduce the pressure in the reactor to -0.1MPa, and maintain the pressure at -0.1MPa for (0.25-1.5) hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com