Continuous chlorine-alkali industry electrolytic alkali production device and method

A technology of chlor-alkali industry and electrolytic cell, applied in the direction of electrolysis process, electrolysis components, electrode coating, etc., can solve the problems of sodium ion inverse concentration difference, dry burning electrodes, low electrolysis efficiency, etc., achieve low energy consumption, reduce power loss and electrode The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

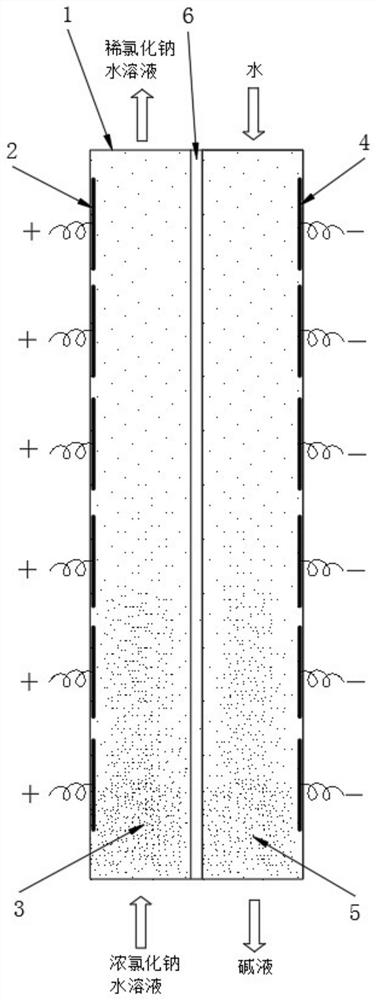

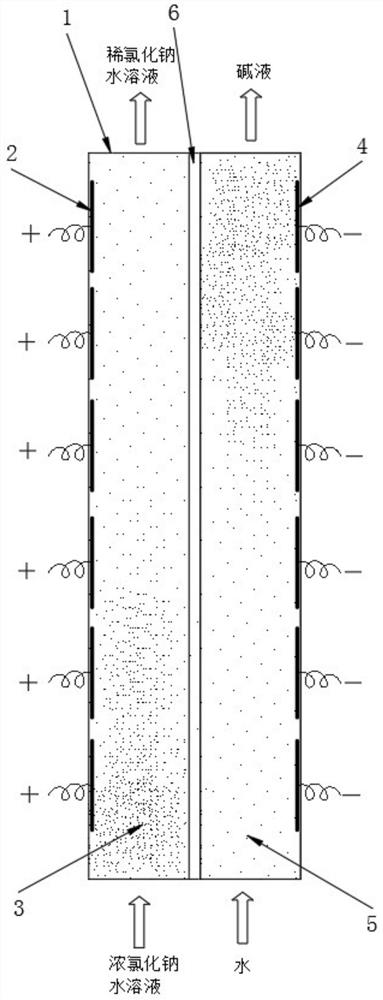

[0027] Such as figure 1 Shown is a continuous chlor-alkali industrial electrolytic alkali production device, the device includes an electrolytic cell 1, and the electrolytic cell 1 includes an anode chamber 3 provided with an anode 2 and a cathode chamber 5 provided with a cathode 4, the anode chamber 3 and cathode chamber 5 are separated by cation exchange membrane 6, and one end of the electrolytic cell 1 is provided with a concentrated sodium chloride aqueous solution inlet and an alkali liquor outlet, and the concentrated sodium chloride aqueous solution inlet is communicated with the anode chamber 3, so that The lye outflow port is communicated with the cathode chamber 5, and the other end of the electrolytic cell 1 is provided with a dilute sodium chloride aqueous solution outflow port and a water inflow inlet, and the dilute sodium chloride aqueous solution outflow port is communicated with the anode chamber 3, and the water inflow inlet It communicates with the cathode...

Embodiment 2

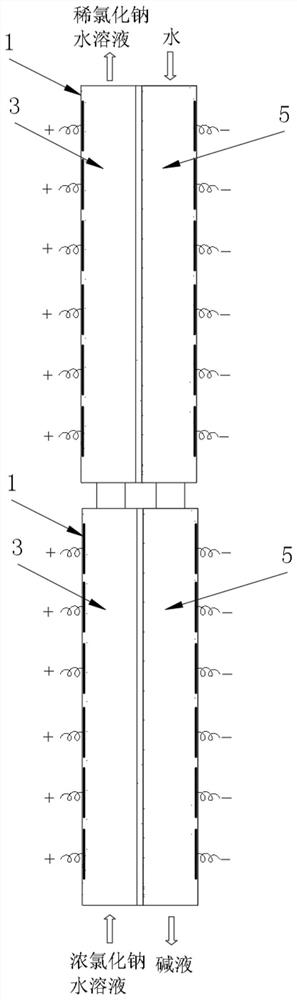

[0041] Such as image 3 Shown is a continuous chlor-alkali industrial electrolytic soda production device, its processing flow and processing system are the same as in Example 1, in order to improve the throughput, it is characterized in that more than two electrolytic cells 1 are connected in series, and the dilute concentration of the previous electrolytic cell 1 The sodium chloride aqueous solution outlet is communicated with the concentrated sodium chloride aqueous solution inlet of the latter electrolytic cell 1, and the lye outlet of the latter electrolytic cell 1 is communicated with the water inlet of the previous electrolytic cell 1. During electrolysis, the effluent from the anode chamber 3 of the previous electrolytic cell 1 flows into the anode chamber 3 of the subsequent electrolytic cell 1, and the effluent from the cathode chamber 5 of the latter electrolytic cell 1 flows into the cathode chamber 5 of the previous electrolytic cell 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com