Sample for measuring doping elements in semiconductor device and preparation method of sample

A technology of doping elements and semiconductors, which is applied in the field of doping element samples and its preparation, can solve the problems of inaccurate measurement and affecting three-dimensional imaging, and achieve the effect of improving accuracy and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

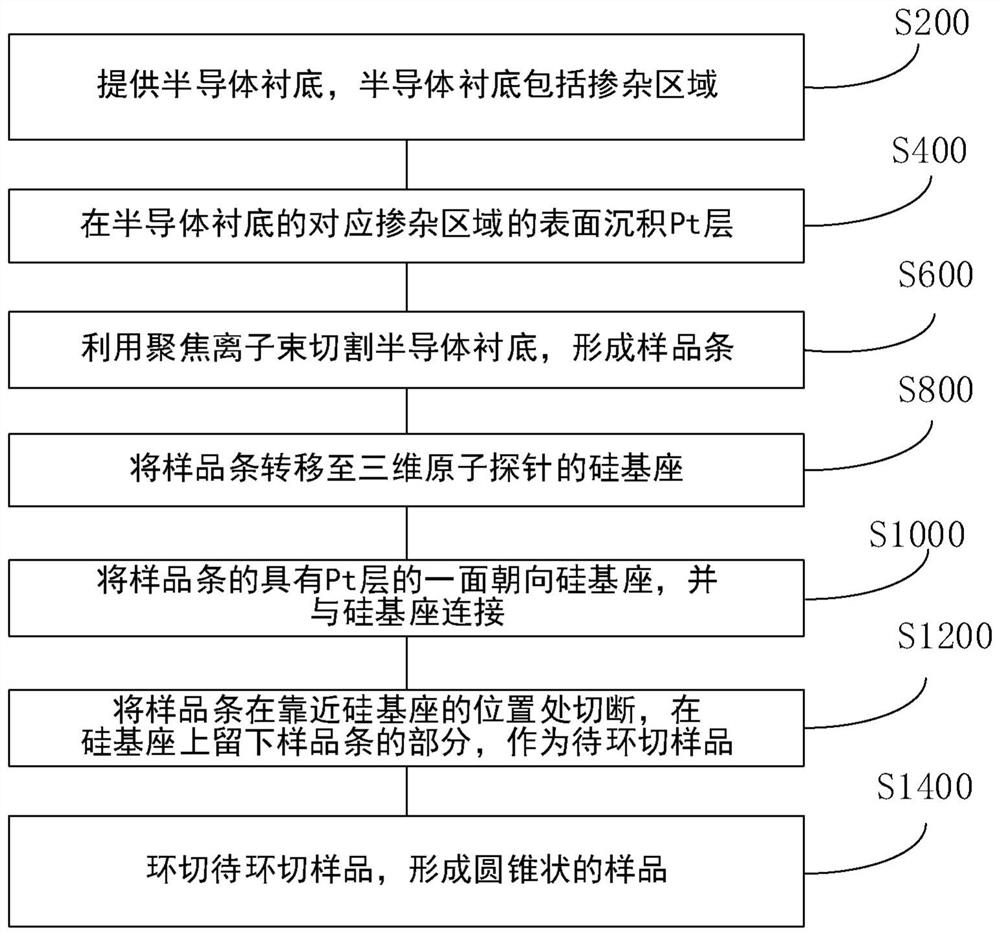

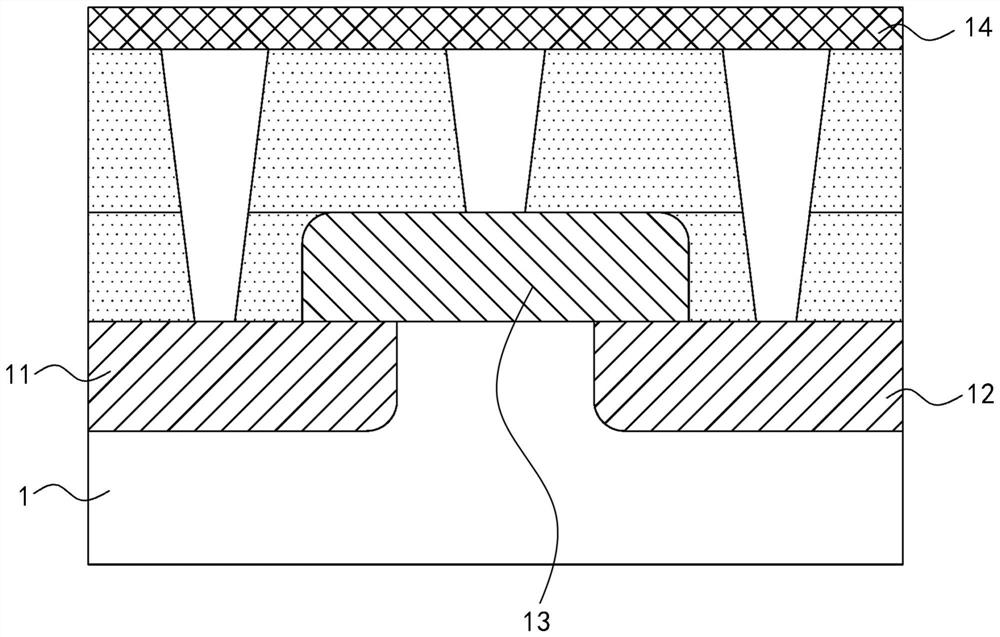

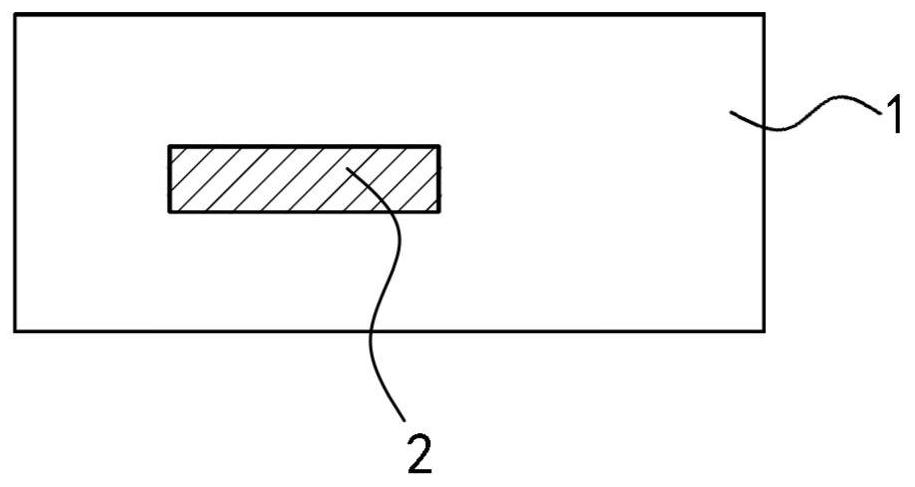

[0042] According to an aspect of the present invention, an embodiment of the present invention provides a method for preparing a sample for measuring dopant elements in a semiconductor device. Such as Figures 1 to 11 As shown, among them, figure 1 shows a flow chart of the preparation method of the present invention, figure 2 A schematic structural view of a semiconductor substrate 1 is shown. Figure 3 to Figure 11 A schematic diagram showing the state of the sample in different steps. Such as figure 1 As shown, the method for preparing a sample for measuring doping elements in a semiconductor device according to an embodiment of the present invention includes:

[0043] Step S200: providing a semiconductor substrate 1 including a doped region.

[0044] Step S400 : depositing a Pt layer 2 on the surface of the corresponding doped region of the semiconductor substrate 1 .

[0045] Step S600 : Cutting the semiconductor substrate 1 with a focused ion beam to form a sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com