Semi-coke quality control method based on resistivity detection and application of method

A quality control method and resistivity technology, applied in the direction of material resistance, can solve problems such as difficult to distinguish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A method for quality control of blue carbon based on electrical resistivity detection, said method comprising the following steps:

[0078] (1) Carry out multi-point sampling from different positions of the blue carbon stockpile to be tested by manual or mechanical sampling method, the number of samples is 30, and each sub-sample is 15 ± 0.5g.

[0079] (2) The selected 15 samples were pulverized with a sample making machine and could all pass through a 200-mesh sieve to make a powder sample to be tested, and then dried in an oven at 105°C for 2 hours;

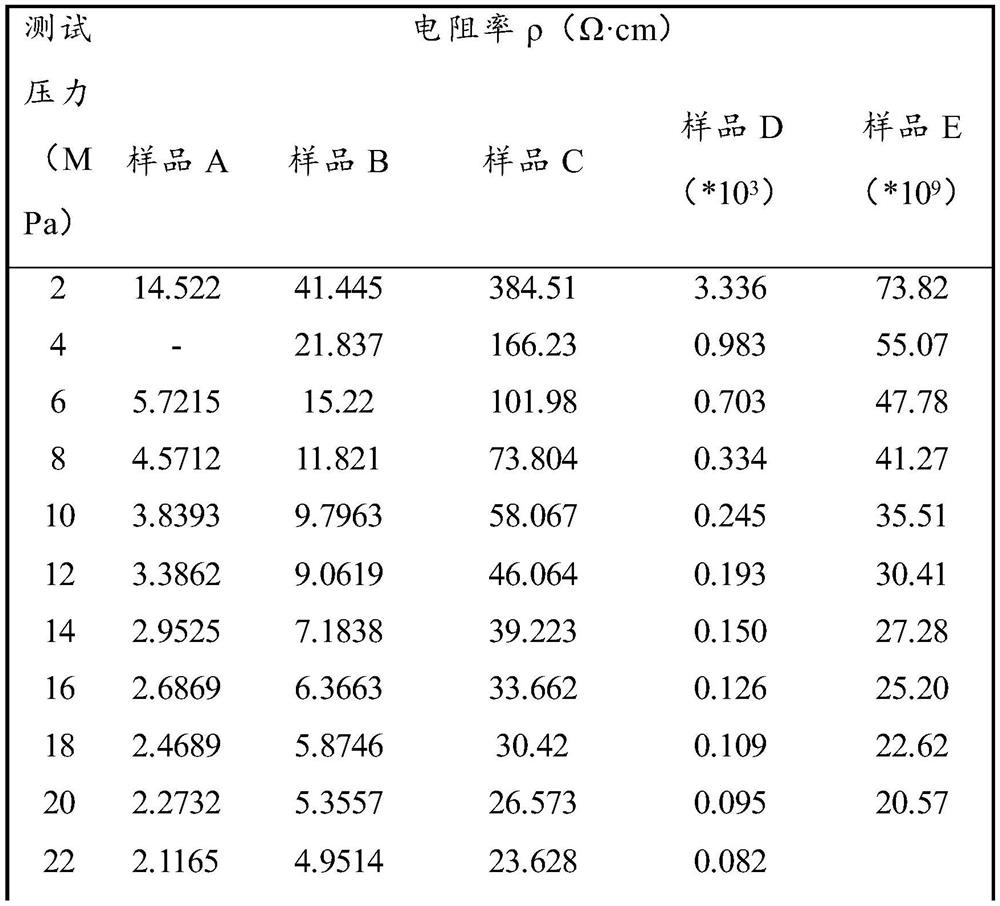

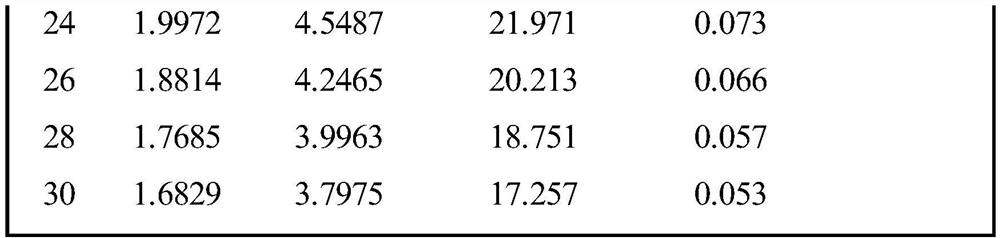

[0080] (3) Use a semiconductor powder resistivity test bench and a four-probe tester to detect the normal temperature conductivity of the powder sample. The test pressure range is 2MPa, and the resistivity change is recorded;

[0081] Find by the record of resistivity, the resistivity order of magnitude of 14 sub-samples in the 15 sub-samples of present embodiment step (2) is 10 4 Ω cm (2Mpa condition), the resistivity ...

Embodiment 2

[0083] A method for quality control of blue carbon based on electrical resistivity detection, said method comprising the following steps:

[0084] (1) Carry out multi-point sampling from different positions of the blue carbon stockpile to be tested by manual or mechanical sampling method, the number of samples is 30, and each sub-sample is 15 ± 0.5g.

[0085] (2) The selected 15 samples were pulverized with a sample making machine and could all pass through a 200-mesh sieve to make a powder sample to be tested, and then dried in an oven at 105°C for 2 hours;

[0086] (3) Use a semiconductor powder resistivity test bench and a four-probe tester to detect the normal temperature conductivity of the powder sample. The test pressure range is 2MPa, and the resistivity change is recorded;

[0087] Find by the record of resistivity, the resistivity order of magnitude of 12 sub-samples among the 15 sub-samples of present embodiment step (2) is identical (being 10 2 Ω·cm, 2Mpa conditio...

Embodiment 3

[0090] A method for quality control of blue carbon based on electrical resistivity detection, said method comprising the following steps:

[0091] (1) Carry out multi-point sampling from different positions of the blue carbon stockpile to be tested by manual or mechanical sampling method, the number of samples is 30, and each sub-sample is 15 ± 0.5g.

[0092] (2) The selected 15 samples were pulverized with a sample making machine and could all pass through a 200-mesh sieve to make a powder sample to be tested, and then dried in an oven at 105°C for 2 hours;

[0093] (3) Use a semiconductor powder resistivity test bench and a four-probe tester to detect the normal temperature conductivity of the powder sample. The test pressure range is 2MPa, and the resistivity change is recorded;

[0094] Find by the record of resistivity, the resistivity order of magnitude of all 15 parts of sample of present embodiment step (2) is all identical (being 10 2 Ω·cm, 2Mpa conditions), it is ju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com