Ultrasonic measurement system for wind speed in front of wind turbine rotor

An ultrasonic measurement, wind turbine technology, applied in the direction of fluid velocity measurement, velocity/acceleration/shock measurement, measuring devices, etc., can solve the lack of equipment fault tolerance and self-calibration function, removal and reinstallation damage the rigidity of the hubcap, high installation accuracy requirements, etc. problems, to achieve the effects of strengthening the scope of application, improving power generation efficiency, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

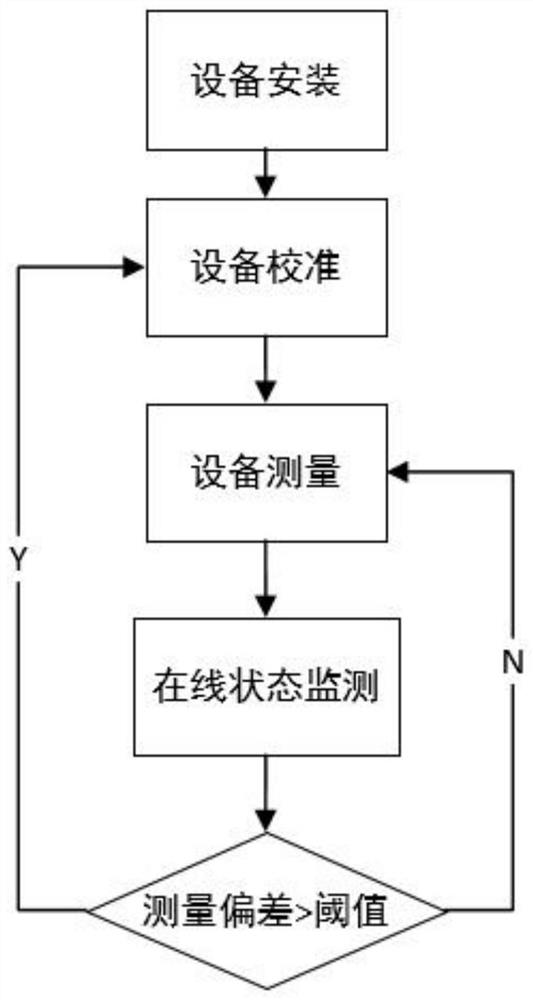

[0046] This embodiment provides an ultrasonic wind speed measurement system in front of a wind turbine rotor. The system has the functions of sound speed calibration under operating conditions, parameter correction (installation correction, operation state correction), on-line measurement of hub center wind speed, and state monitoring.

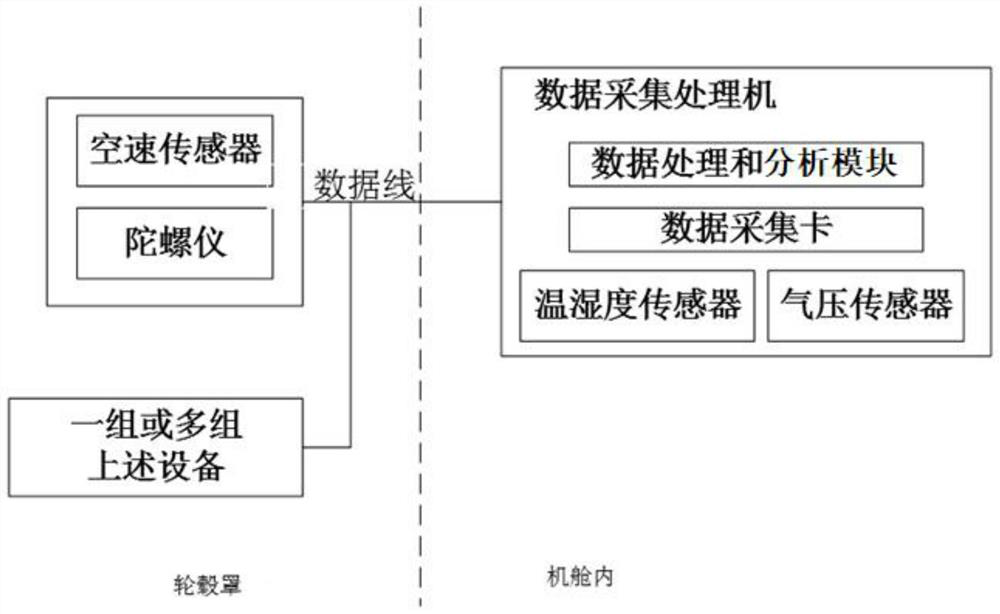

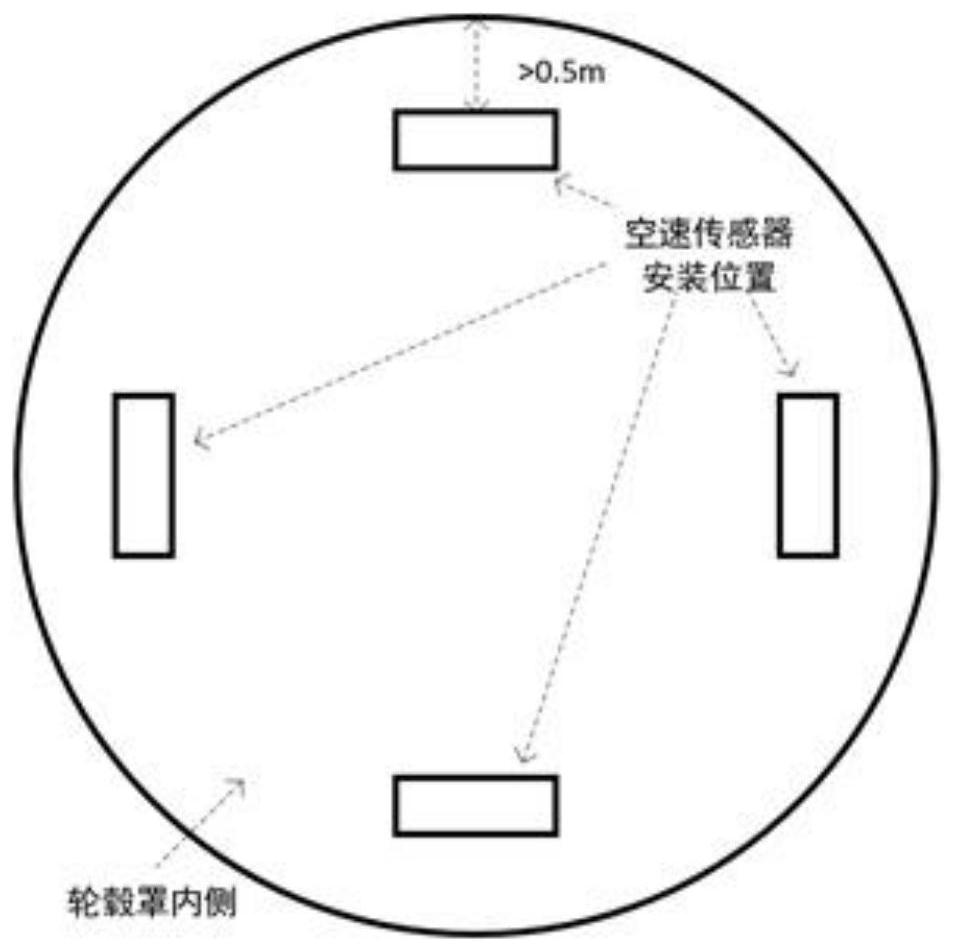

[0047] ginseng figure 1 As shown, the wind speed ultrasonic measurement system in front of the wind turbine rotor includes an airspeed sensor and a gyroscope installed in the hubcap, and a data acquisition processor installed in the nacelle. The data acquisition processor integrates a temperature and humidity sensor, an air pressure senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com