Flexible pressure sensor based on multilayer composite film and preparation method thereof

A pressure sensor, multi-layer composite technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further explained below in conjunction with the accompanying drawings.

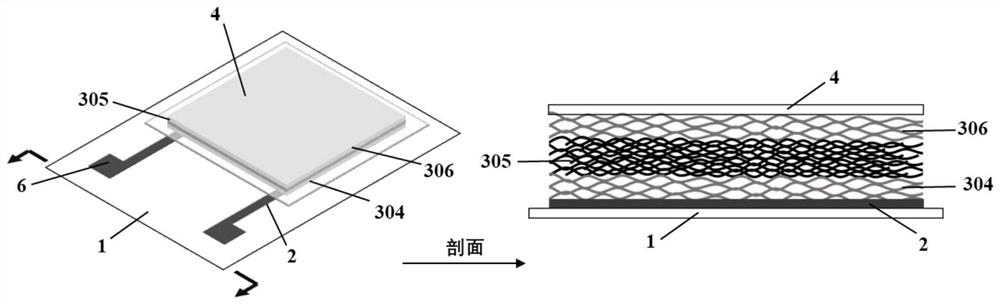

[0034] like figure 1 As shown, a flexible pressure sensor based on a multilayer composite film includes a substrate layer 1 , an electrode layer 2 , a pressure sensitive layer 3 and a top protective layer 4 sequentially arranged from bottom to top.

[0035] The electrode layer 2 adopts an interdigitated electrode structure 5 and a bonding pad 6 for electrical extraction. The electrode material of the electrode layer 2 is a metal double-sided conductive tape, and the two sides are adhered to the substrate layer 1 and the pressure sensitive layer 3 respectively. The substrate layer 1 and the top protection layer 4 are flexible organic material films.

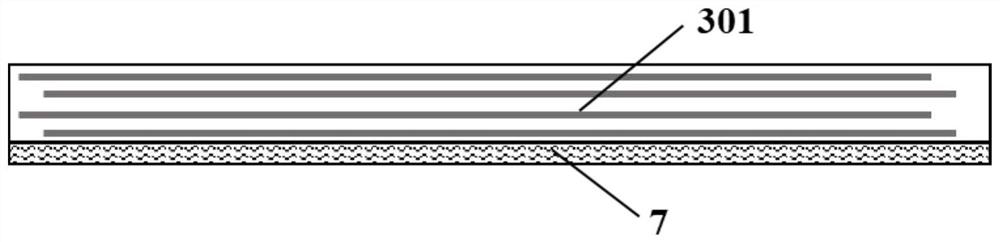

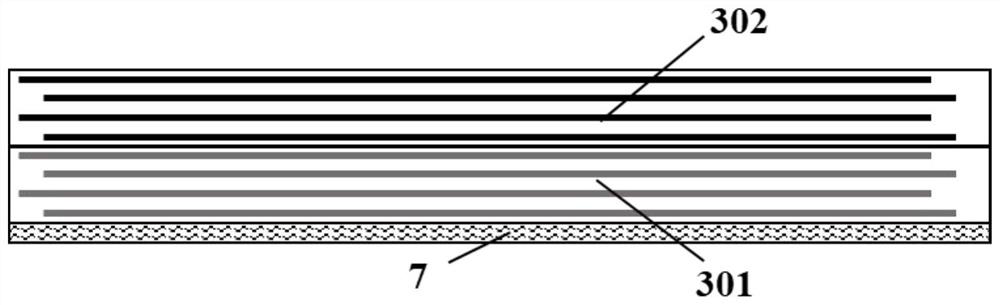

[0036] The pressure-sensitive layer 3 is composed of a first layer of reduced graphene oxide film 304, a porous two-dimensional transition metal carbide film layer 305, a second layer of reduced graphene oxide film 306, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com