A method for temperature control in a sintering flue gas multi-pollutant treatment process

A sintering flue gas and temperature control technology, which is applied in the temperature control of sintering flue gas multi-pollutant treatment process, and in the field of temperature control in flue gas treatment, can solve the problems of large fluctuations in sintering flue gas pollutant components, and achieve outstanding results , reduce consumption and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

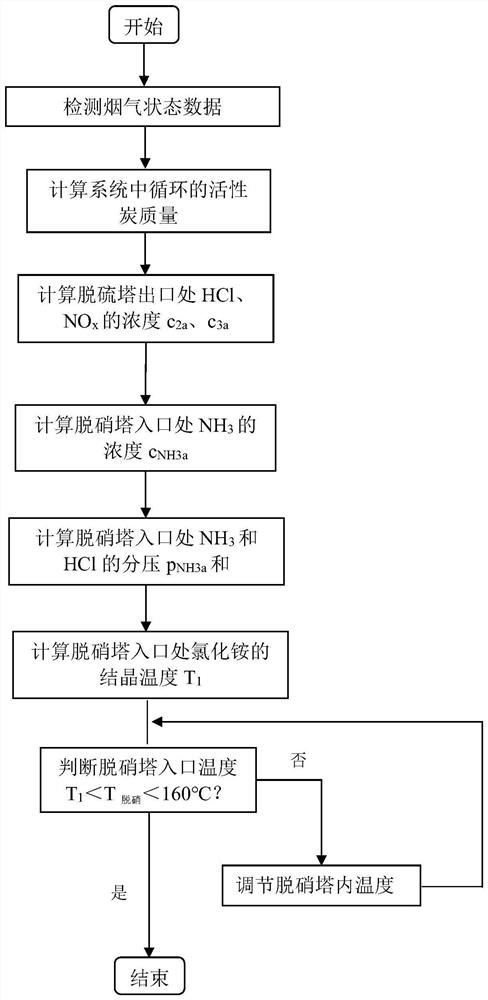

[0160] A method for temperature control in a sintering flue gas multi-pollutant treatment process, the method comprising the following steps:

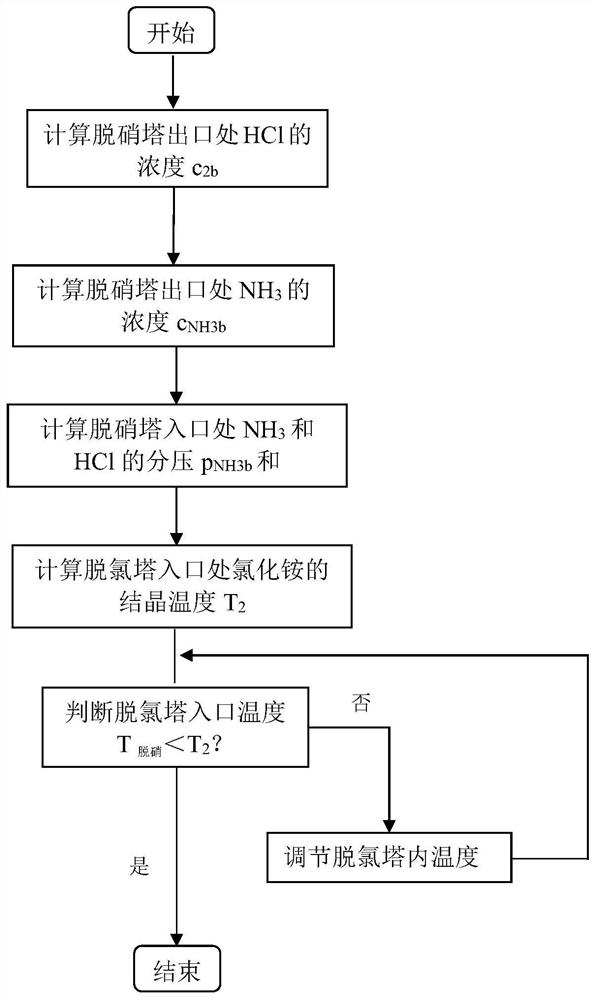

[0161] 1) The sintering flue gas enters the denitration tower after being adsorbed and desulfurized by activated carbon in the desulfurization tower, and enters the dechlorination tower after being adsorbed and denitrated by activated carbon in the denitrification tower, and finally discharged from the dechlorination tower;

[0162] 2) Activated carbon circulates among the desorption tower, denitrification tower and desulfurization tower;

[0163] It is characterized in that: a detection device is installed at the entrance of the desulfurization tower to obtain the state data of the sintering flue gas at the entrance of the desulfurization tower; the state data of the sintering flue gas includes the total flow rate of the sintering flue gas and the initial concentration of each gas component in the sintering flue gas, In order to deter...

Embodiment 2

[0165] Repeat Example 1, only to determine the flow rate of the activated carbon to be circulated. Specifically: according to the total flow rate of the sintering flue gas and the content of sulfur dioxide in the sintering flue gas, determine the circulation amount of the activated carbon. According to the adsorption capacity of activated carbon for each gas and the initial concentration of each gas component in the sintering flue gas, the safe temperature range when the sintering flue gas enters the denitrification tower and the dechlorination tower is calculated as follows: detecting the total flow rate of the sintering flue gas, The initial concentration of nitrogen oxides and hydrogen chloride in the sintering flue gas, and calculate the partial pressure of nitrogen oxides and hydrogen chloride at the inlet of the denitrification tower and dechlorination tower according to the adsorption capacity of activated carbon for different gas components; The partial pressure at the ...

Embodiment 3

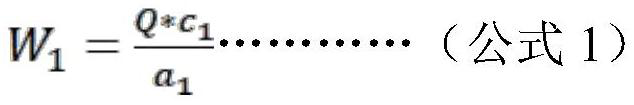

[0167] Repeat Example 2, only measure the total flow Q of the sintering flue gas at the inlet of the desulfurization tower, the amount of SO in the flue gas 2 Concentration c 1 ,Available:

[0168]

[0169] In the formula, Q is the sintering flue gas flow rate at the inlet of the desulfurization tower, Nm 3 / h. c 1 is the SO in the sintering flue gas at the inlet of the desulfurization tower 2 Concentration, mg / Nm 3 . a 1 Activated carbon for SO 2 Adsorption capacity, mg / kg-AC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com