Production method of 1500MPa-grade ultrahigh-strength Zn-Cr composite coating hot-formed steel

A technology of ultra-high strength and production method, which is applied in the field of rolling to achieve the effect of preventing surface oxidation and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

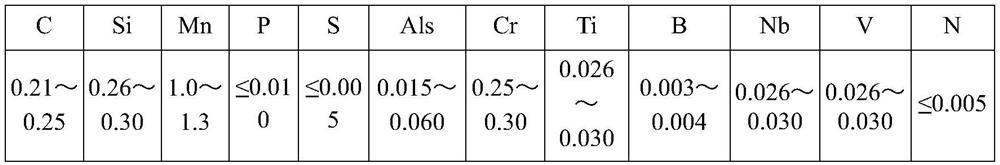

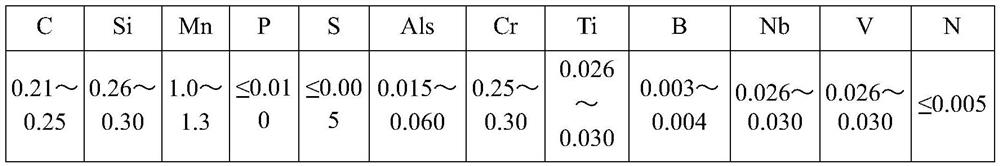

[0023] Substrate

[0024] The steel plate is designed with MnB composition: C: 0.21~0.25, Si: 0.26~0.30, Mn: 1.0~1.3, P: ≤0.010, S: ≤0.005, Als: 0.015~0.060, Cr: 0.25~0.30, Ti: 0.026~ 0.030, B: 0.003~0.004, Nb: 0.026~0.030, V: 0.026~0.030, N: ≤0.005

[0025] A method for manufacturing ultra-high-strength hot-formed steel with a Zn-Cr composite coating of 0.8 to 2.0 mm in thickness by direct rolling of medium and thin slabs, mainly including electric furnace or converter smelting, refining, continuous casting of medium and thin slabs, and soaking of slabs , rolling, laminar cooling, coiling, electrochrome plating and electrogalvanizing, heating austenitization, die stamping forming quenching.

[0026] The superheat of molten steel in tundish is 15~30℃;

[0027] The slab thickness of the medium-thin slab continuous casting is 52-55mm, and the casting speed is 3.7-7.0m / s;

[0028] Descaling treatment is carried out before the slab of the medium-thin slab continuous casting is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com