Device and method for evaluating seepage performance of oil-displacing agent

An evaluation device and oil displacement agent technology, which is applied in the field of oil displacement agent seepage performance evaluation device, can solve the problems of accurately measuring the oil displacement agent seepage performance, and achieve the effect of high accuracy, high precision and stable injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

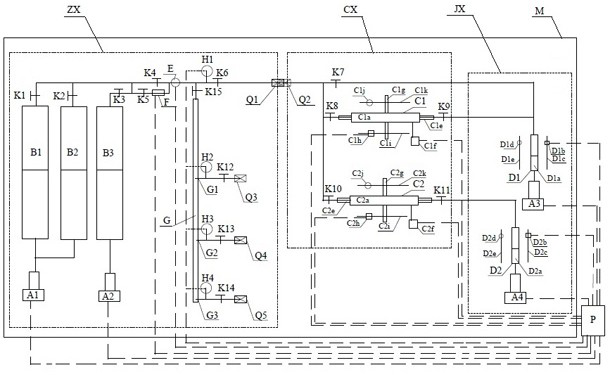

[0053] Such as figure 1 As shown, this oil displacement agent seepage performance evaluation device includes an injection system ZX, a measurement system CX, a metering system JX, an incubator M, and a computer P. The solid line in the figure indicates the physical pipeline connection, and the dotted line indicates the electrical connection.

[0054] (1) Injection system ZX

[0055] Injection system ZX includes constant speed and constant pressure pump A1, constant speed and constant pressure pump two A2, piston container one B1, piston container two B2, piston container three B3 and shearing device E; the top of piston container one B1 passes through the pipeline, valve one K1 and valve four K4 are connected with the shearing device E, and the bottom end of the piston container-B1 is connected with the constant-speed constant-pressure pump-A1 through a pipeline. The top of the piston container two B2 is connected with the shearing device E through the pipeline, the valve two...

Embodiment 2

[0085] A method for evaluating the seepage performance of an oil-displacing agent, using the above-mentioned device to evaluate the seepage performance of the oil-displacing agent, comprising the following steps:

[0086] Step 1: Fill the upper part of piston container 1 B1 with oil displacing agent, the piston in metering piston container 1 D1 is located at the top, connect quick connector 1 Q1 and quick connector 2 Q2, close all valves, open insulation box M and heat to the test temperature.

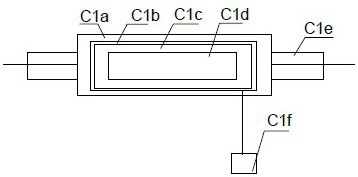

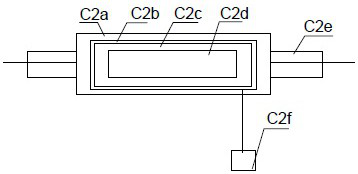

[0087] Step 2. According to the experimental requirements, set the rotation angle of the core holder-C1 around the longitudinal axis-C1g and the transverse axis-C1e, put the core-C1c in the transparent rubber sleeve-C1b, and pass through the ring pressure tracker-C1f Inject water between the shell of the core holder C1a and the transparent rubber sleeve C1b, and the pressure of the injected water is the pressure required by the experiment. During the experiment, the ring pressure track...

Embodiment 3

[0091] A method for evaluating the seepage performance of an oil-displacing agent, using the above-mentioned device to evaluate the seepage performance of the oil-displacing agent, comprising the following steps:

[0092] Step 1: Fill the upper part of piston container 1 B1 with oil displacing agent, the upper part of piston container 2 B2 with oil, and the upper part of piston container 3 B3 with gas, the pistons in metering piston container 1 D1 and metering piston container 2 D2 are located at the top, close All valves are opened and the incubator M is heated to the experimental temperature.

[0093] Step 2. According to the experimental requirements, set the rotation angle of the core holder-C1 around the longitudinal axis-C1g and the transverse axis-C1e, put the water-saturated core-C1c in the transparent rubber sleeve-C1b, and track through the ring pressure Device one C1f injects water between the core holder shell one C1a and the transparent rubber sleeve one C1b, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com