Mesoporous ZSM-5 molecular sieve with short pore depth and application thereof in preparation of pyridine base

A ZSM-5, molecular sieve technology, applied in molecular sieve catalyst, organic chemistry, crystalline aluminosilicate zeolite, etc., can solve the problems of deep mesoporous pores, low yield and short life of the catalyst, and achieve rich oxidation centers, Extend catalyst life and reduce carbon deposition

Inactive Publication Date: 2021-10-22

鄂尔多斯应用技术学院

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

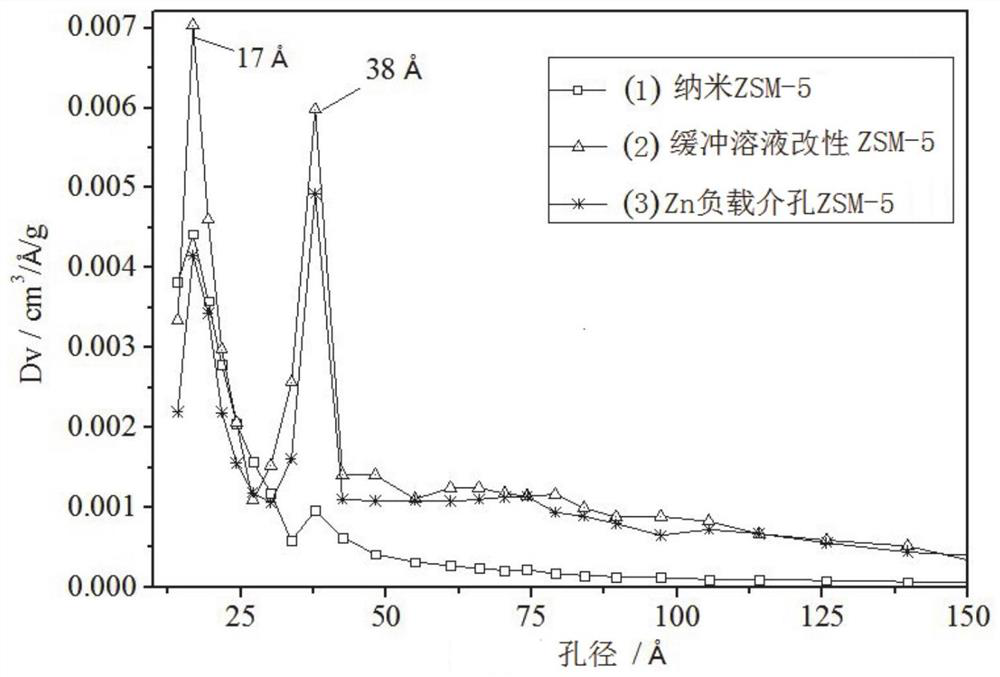

However, in the research of Qin Hongwen and Liu Juanjuan, due to the deep mesopores of the catalyst, it is easy to deposit carbon and lead to short life, so the yield is not high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0030] The following clearly and completely describes the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a mesoporous ZSM-5 molecular sieve with short pore depth. The molecular sieve is prepared by the following steps: S1, preparing a buffer solution; S2, preparing a NaZSM-5 molecular sieve; S3, preparing a mesoporous HZSM-5 molecular sieve with a short pore depth; and S4, preparing the mesoporous ZSM-5 molecular sieve with a short pore depth. The invention also discloses an application of the mesoporous ZSM-5 molecular sieve with a short pore depth. The application comprises the following steps: S1, activating a catalyst; and S2, preparing pyridine base. According to the method for preparing the pyridine base by catalyzing the alcohol-ammonia reaction through the mesoporous ZSM-5 molecular sieve with a short hole depth prepared by treating the nano ZSM-5 molecular sieve with the buffer solution, the metal-supported mesoporous ZSM-5 molecular sieve catalyst with a short hole depth can be obtained, and the conversion rate of the alcohol-ammonia reaction and the yield of the pyridine base product are improved.

Description

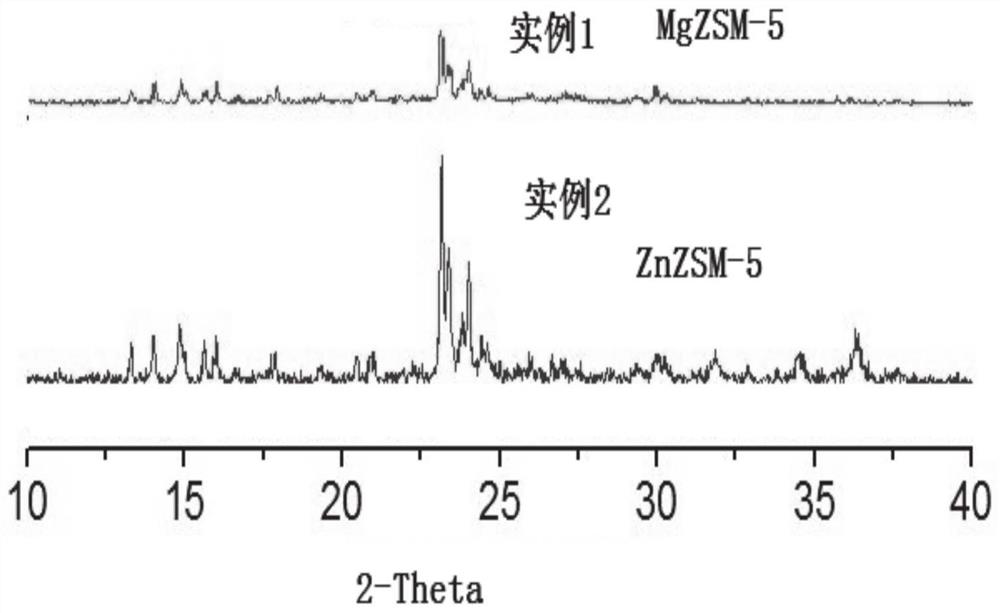

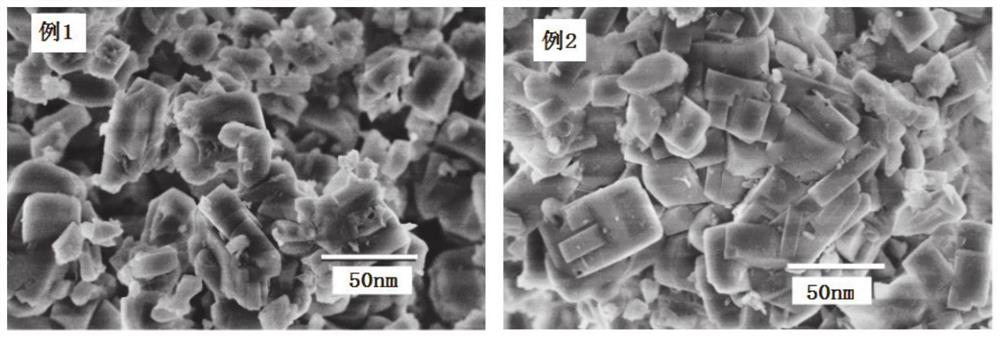

Technical field: [0001] The invention relates to a molecular sieve and its application, in particular to a short-pore-deep mesoporous ZSM-5 molecular sieve and its application in catalyzing the reaction of alcohol and ammonia to prepare pyridine base. Background technique: [0002] Pyridine base mainly includes pyridine and picoline. It is the main raw material for the preparation of pharmaceutical intermediates, pesticide intermediates and fine chemicals, and is also an important intermediate for the synthesis of pyridine-like spices and new pesticides. The supply is in short supply. [0003] At present, pyridine base is mainly produced by aldehyde-ammonia synthesis method, but there are disadvantages such as acetaldehyde is not easy to transport, dependence on petroleum raw materials, etc. In particular, there are problems such as short reaction catalyst life, serious product polymerization and high equipment investment. The preparation of pyridine base by the alcohol ammo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B39/38B01J29/40C07D213/09

CPCC01B39/38B01J29/40C07D213/09C01P2002/72C01P2004/03C01P2006/17

Inventor 张弦

Owner 鄂尔多斯应用技术学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com