Coffee residue biochar and method for removing urea in water

A coffee grounds, biochar technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as weak urea absorption capacity, inability to destroy urea N bonds, and inability to be removed by charge repulsion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a preparation method of modified coffee grounds biochar, comprising: calcining coffee grounds at a high temperature for the first time under oxygen-limited conditions, and after grinding, obtaining coffee grounds biochar; The second high-temperature calcination obtains the modified coffee grounds biochar.

[0028] Among them, the present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0029] The coffee grounds are the remaining residues of coffee drinks prepared from coffee beans, and the raw materials of the present invention can be obtained after drying; in the present invention, the coffee grounds are preferably vacuum-dried first; the vacuum drying temperature is preferably 100°C~ 110°C, more preferably 105°C; the vacuum drying time is preferably 20-30 h, more preferably 22-26 h, and more preferably 24 h.

[0030] After vacuum drying, the first high-temperature calcination is car...

Embodiment 1

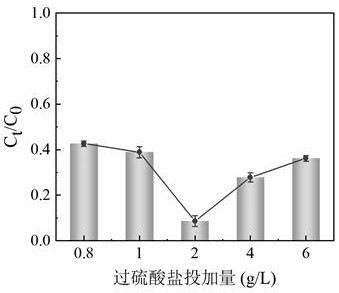

[0043] A preparation of modified coffee grounds biochar and its removal effect on low-concentration urea under different dosages of sodium persulfate, comprising the following steps:

[0044] 1.1 Put the dried coffee grounds in a vacuum oven at 105°C for 24 hours;

[0045] 1.2 Put the coffee grounds in a ceramic crucible, wrap it with aluminum foil, put the lid on and put it in a muffle furnace, heat it up to 900°C at a heating rate of 5°C / min, and keep it for 2 hours. After natural cooling, turn on the furnace and take it out ;

[0046] 1.3 Grind the cooled biochar through an 80-mesh sieve to obtain the coffee grounds biochar product;

[0047] 1.4 Put the coffee grounds biochar in a ceramic crucible, put it in a muffle furnace, heat it up to 550°C at a heating rate of 2°C / min, and keep it for 4 hours. After natural cooling, turn on the furnace and take it out to get the final modified charcoal. Sexual coffee grounds biochar products;

[0048] 1.5 Add 400 mL of 1 mg / L urea ...

Embodiment 2

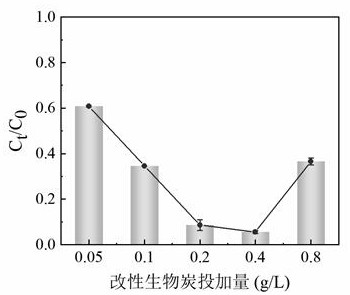

[0051] The modified biochar prepared in Example 1 of the present invention was placed in urea solution with different dosages for catalysis.

[0052] Add 400 mL of 1 mg / L urea solution to a 500 mL Erlenmeyer flask without adjusting the initial pH of the solution. Afterwards, the biochar samples (0.05, 0.1, 0.2, 0.4, 0.8 g / L) prepared in Experimental Case 1 were accurately weighed into 500 mL Erlenmeyer flasks, and 2 g / L persulfate was added to induce the reaction. Place the Erlenmeyer flask in a constant temperature shaker (180 r / min, 25°C), and stop the reaction after 5 hours. After passing the obtained sample through a filter membrane of 45 μm, the absorbance of the filtrate was measured by UV, and the concentration was converted and recorded according to the standard curve of urea, and the results were obtained as follows: figure 2 shown. All experiments were performed in triplicate and the results were averaged.

[0053] Depend on figure 2 It can be seen that the use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com