System and method for preparing propylene from isopropanol

A technology for dehydration of isopropanol and isopropanol, which is applied in the field of propylene, can solve problems such as unusable, and achieve the effects of high recovery rate, high purity of propylene, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

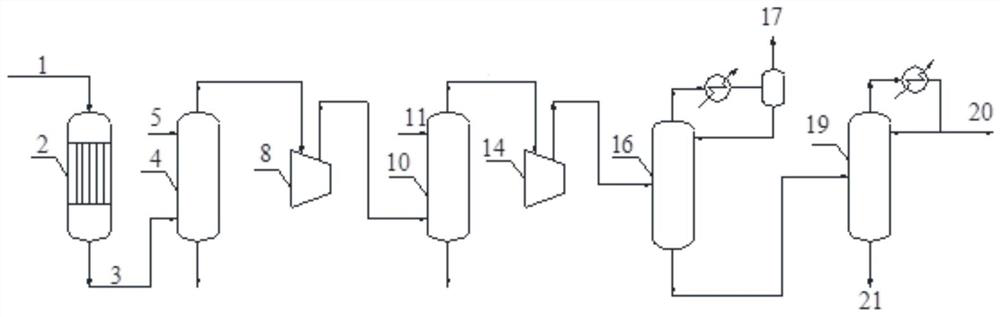

[0108] like figure 1 As shown, a system of propylene propylene is propylene. Including: isopropanol dewatering reactor 2, water washing tower 4, base wash tower 10, degaussing tower 16, propylene column 19; isopropanol dewatering reactor 2 is connected to the water washing tower 4, the top of the water washing tower 4 is connected to the compressor 8 Connect the base washing tower 10, the base of the base wash tower 10 is connected to the compressor B14, and the deprinted column 16 is connected, the propylene column 19 is attached to the bottom of the tower 16.

[0109] Methods include:

[0110] Isopropyl alcohol 1 enters isopropanol dehydration reactor 2, the reaction operating temperature is 220 ° C, and the pressure is 0.03 MpAg. Isopropanol dehydration to form propylene and other small by-products;

[0111] The reaction product 3 enters the bottom of the water washing tower 4, and the water 5 is inserted from the top of the tower, and the water, aldehyde, etc. are removed from...

Embodiment 2

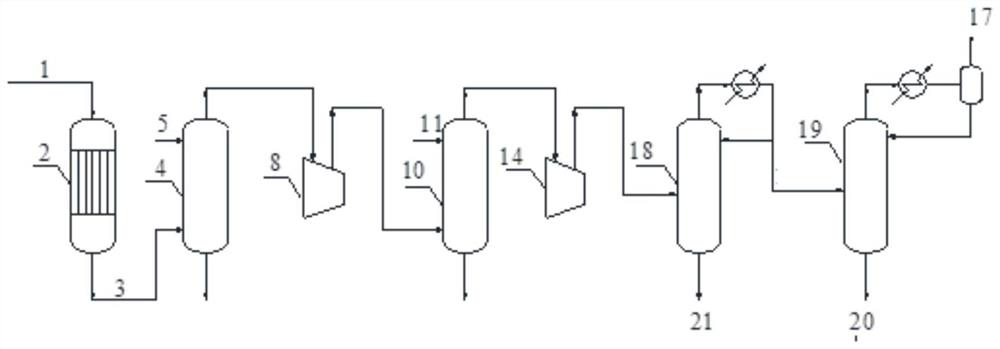

[0124] like figure 2 As shown, a system of propylene propylene is propylene. Including: isopropanol dewatering reactor 2, water washing tower 4, base wash tower 10, rehabilitating tower 18, propylene column 19; isopropanol dewatering reactor 2 bottom connection water washing tower 4, water washing tower 4 connected to compressor 8 The base wash tower 10 is connected, the base wash tower 10 is connected to the compressor B14 after connecting the reinforced tower 18, and the top of the reward tower 18 is attached to the propylene column 19.

[0125] Methods include:

[0126] Isopropyl alcohol 1 into the isopropyl alcohol dehydration reactor 2, the reaction operating temperature is 330 ° C, and the operating pressure is 0.08 MpAg. Isopropanol dehydration to form propylene and other small by-products;

[0127] The reaction product 3 enters the bottom of the water washing tower 4, and the water 5 is inserted from the top of the column, and the water, aldehyde, etc. are removed from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com