Synthesis method of vinylene carbonate for electrolyte

A technology of vinylene carbonate and ethylene carbonate, which is applied in the field of synthesis of vinylene carbonate for electrolyte, can solve the problems of unrealized continuous production of chloroethylene carbonate, shorten the synthesis time, reduce side reactions, reduce The effect of process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

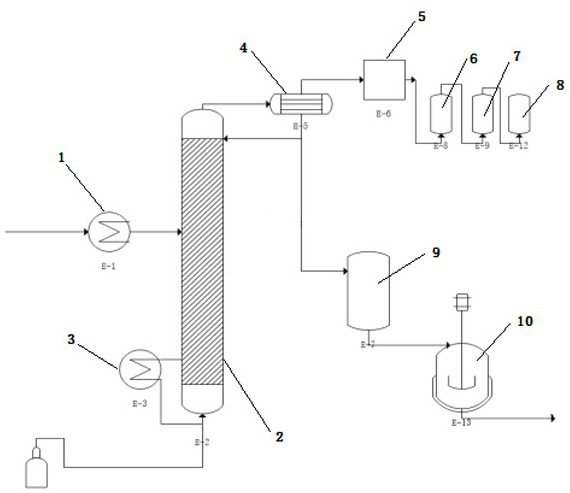

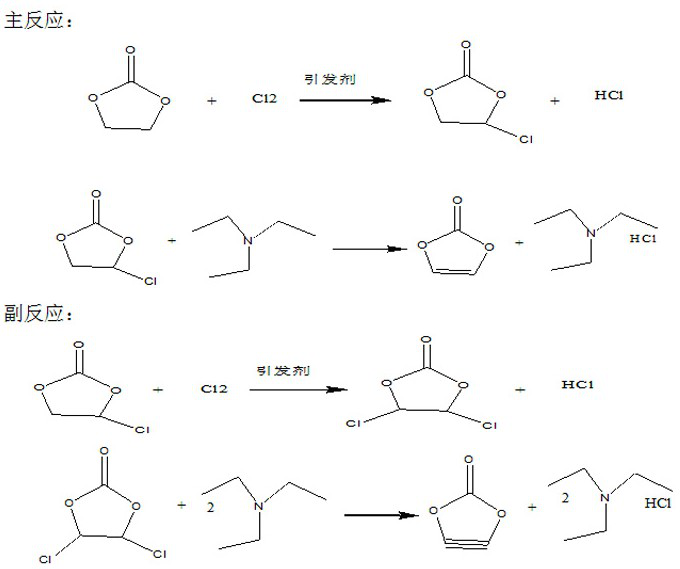

[0030] see figure 1 , the present invention provides a technical solution for the synthesis of vinylene carbonate for electrolyte solution, and realizes the synthesis and purification of vinylene carbonate through a synthesis and purification device, specifically comprising the following steps:

[0031] S1, feed the raw material ethylene carbonate and initiator into the raw material preheater 1 through a metering pump, control the outlet temperature of the raw material preheater at 40-70°C, enter from the middle and upper part of the reactive distillation tower 2, and the mass of the initiator added is 0.1%~1% of the mass of ethylene carbonate;

[0032] S2, chlorine gas enters in the reactive distillation tower 2 from the bottom of the tower, and the molar weight of the chlorine gas that is introduced is 1 to 1.1 times of the molar weight of ethylene carbonate, and the flow rate of the reactive distillation tower 2 is controlled by adjusting the heat transfer oil flow rate of...

Embodiment 1

[0037] A technical scheme of a vinylene carbonate synthesis method for an electrolyte, which realizes the synthesis and purification of vinylene carbonate through a synthesis and purification device, specifically comprising the following steps:

[0038] S1, feed the raw material ethylene carbonate and initiator into the raw material preheater 1 through a metering pump, control the outlet temperature of the raw material preheater to 40°C, and enter from the upper middle part of the reactive distillation tower 2, and the mass of the initiator added is ethylene carbonate 0.1% of ester mass;

[0039] S2, chlorine gas enters the reactive distillation tower 2 from the bottom of the tower, and the molar weight of the chlorine gas introduced is 1 time of the molar weight of ethylene carbonate, and the tower still of the reactive distillation tower 2 is controlled by adjusting the heat conduction oil flow rate of the reboiler 3 The temperature is at 50°C, and the vacuum degree of the r...

Embodiment 2

[0044] A technical scheme of a vinylene carbonate synthesis method for an electrolyte, which realizes the synthesis and purification of vinylene carbonate through a synthesis and purification device, specifically comprising the following steps:

[0045] S1, feed the raw material ethylene carbonate and initiator into the raw material preheater 1 through a metering pump, control the outlet temperature of the raw material preheater to 70°C, and enter from the middle and upper part of the reactive distillation tower 2, and the mass of the initiator added is ethylene carbonate 1% of ester mass;

[0046] S2, chlorine gas enters the reactive distillation tower 2 from the bottom of the tower, and the molar weight of the chlorine gas introduced is 1.1 times that of ethylene carbonate molar weight, and the tower still of the reactive distillation tower 2 is controlled by adjusting the heat conduction oil flow rate of the reboiler 3 The temperature is at 80°C, and the vacuum degree of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com