Semiconductor hydrocarbon cleaning agent and preparation method thereof

A hydrocarbon cleaning agent and semiconductor technology, applied in the preparation of detergent mixture composition, detergent composition, detergent compounding agent, etc., can solve the problems of low VOCs content, achieve good material compatibility, and enhance cleaning performance, superior synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

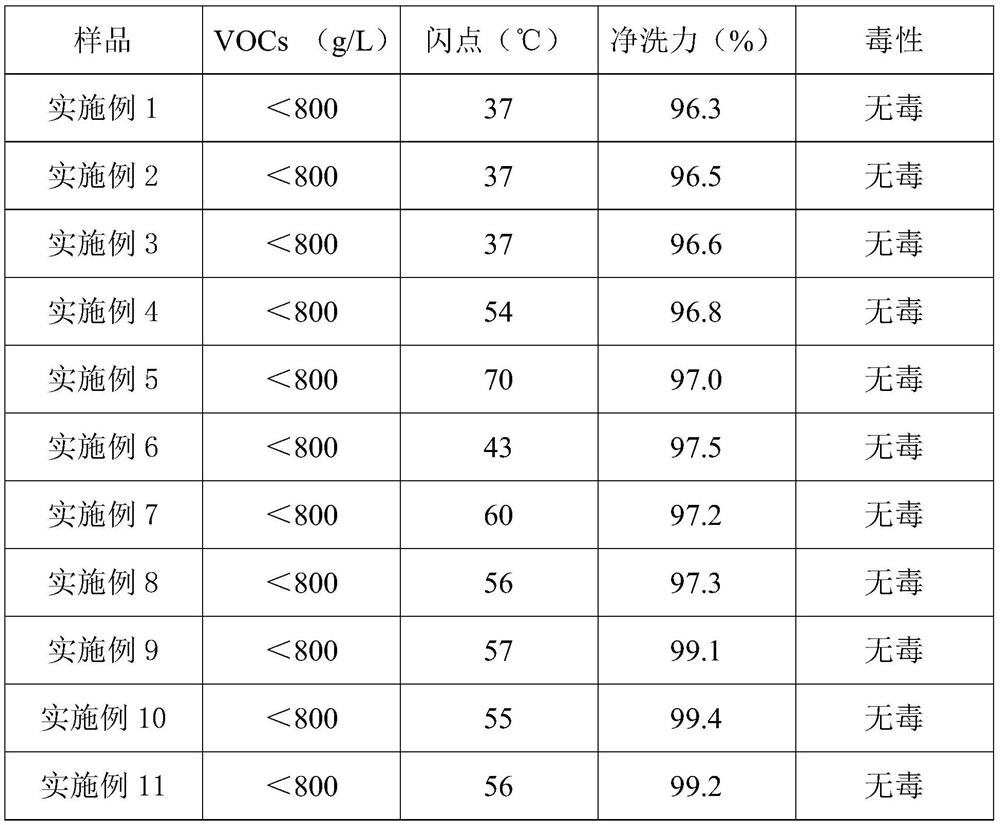

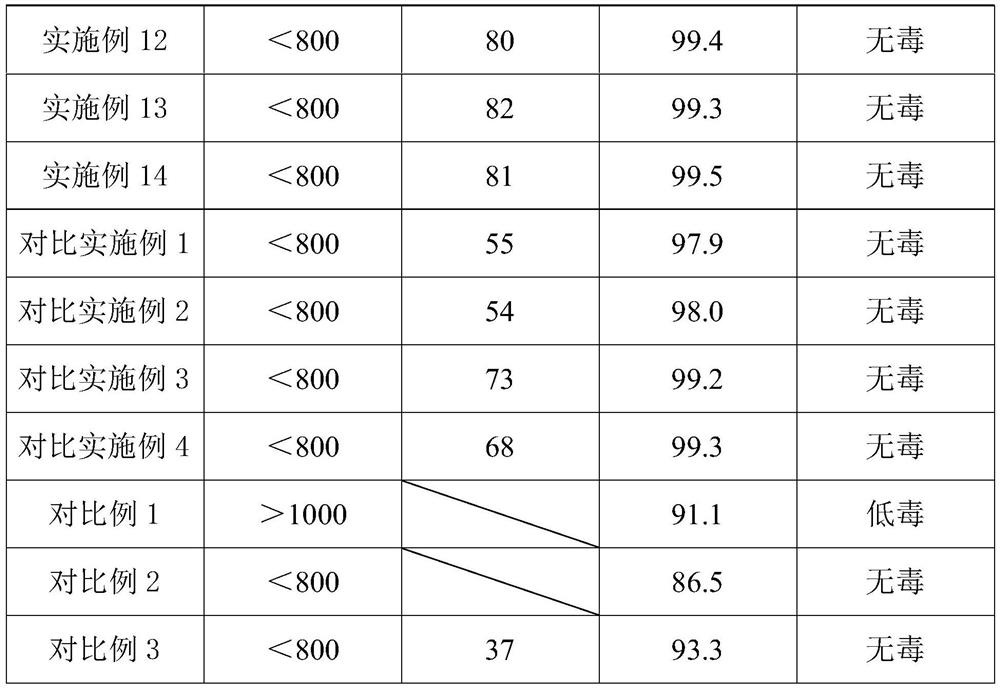

Examples

Embodiment 1

[0043] A hydrocarbon cleaning agent for semiconductors, made from raw materials containing the following parts by weight: nonane 40kg, 3-butoxy-1-propanol 10kg, HFC-4310mee 1kg, 365AZ-M 0.1kg, diethylene glycol 0.5kg of butyl ether and 0.1kg of fatty alcohol polyoxyethylene ether.

[0044] The preparation method of the hydrocarbon cleaning agent of semiconductor, specifically comprises the following steps:

[0045]S1. Weigh 40kg of nonane, 10kg of 3-butoxy-1-propanol, 1kg of HFC-4310mee, 0.1kg of 365AZ-M, 0.5kg of diethylene glycol butyl ether and 0.1kg of fatty alcohol polyoxyethylene ether;

[0046] S2. At room temperature, first mix nonane and 3-butoxy-1-propanol evenly to prepare mixed solution A;

[0047] S3. At room temperature, mix HFC-4310mee, 365AZ-M, diethylene glycol butyl ether and fatty alcohol polyoxyethylene ether evenly to prepare a mixed solution B;

[0048] S4. At room temperature, pour the mixed solution B into the mixed solution A and stir evenly to prepa...

Embodiment 2

[0051] A hydrocarbon cleaning agent for semiconductors, made from raw materials containing the following parts by weight: nonane 60kg, 3-butoxy-1-propanol 35kg, HFC-4310mee 3kg, 365AZ-M 5.2kg, diethylene glycol 2.75kg of butyl ether and 2.55kg of fatty alcohol polyoxyethylene ether.

[0052] The preparation method of the hydrocarbon cleaning agent of semiconductor, specifically comprises the following steps:

[0053] S1. Weigh 60kg of nonane, 35kg of 3-butoxy-1-propanol, 3kg of HFC-4310mee, 5.2kg of 365AZ-M, 2.75kg of diethylene glycol butyl ether and 2.55kg of fatty alcohol polyoxyethylene ether;

[0054] S2. At room temperature, first mix nonane and 3-butoxy-1-propanol evenly to prepare mixed solution A;

[0055] S3. At room temperature, mix HFC-4310mee, 365AZ-M, diethylene glycol butyl ether and fatty alcohol polyoxyethylene ether evenly to prepare a mixed solution B;

[0056] S4. At room temperature, pour the mixed solution B into the mixed solution A and stir evenly to ...

Embodiment 3

[0059] A hydrocarbon cleaning agent for semiconductors, made from raw materials containing the following parts by weight: 80kg of nonane, 60kg of 3-butoxy-1-propanol, 5kg of HFC-4310mee, 10kg of 365AZ-M, butylene glycol Ether 5kg and fatty alcohol polyoxyethylene ether 5kg.

[0060] The preparation method of the hydrocarbon cleaning agent of semiconductor, specifically comprises the following steps:

[0061] S1. Weigh nonane 80kg, 3-butoxy-1-propanol 60kg, HFC-4310mee 5kg, 365AZ-M10kg, diethylene glycol butyl ether 5kg and fatty alcohol polyoxyethylene ether 5kg;

[0062] S2. At room temperature, first mix nonane and 3-butoxy-1-propanol evenly to prepare mixed solution A;

[0063] S3. At room temperature, mix HFC-4310mee, 365AZ-M, diethylene glycol butyl ether and fatty alcohol polyoxyethylene ether evenly to prepare a mixed solution B;

[0064] S4. At room temperature, pour the mixed solution B into the mixed solution A and stir evenly to prepare the mixed solution C;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com