Bacteriostatic laundry detergent and preparation method thereof

A technology of laundry detergent and deionized water, applied in the field of daily chemical products, can solve problems such as the safety of antibacterial laundry detergent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

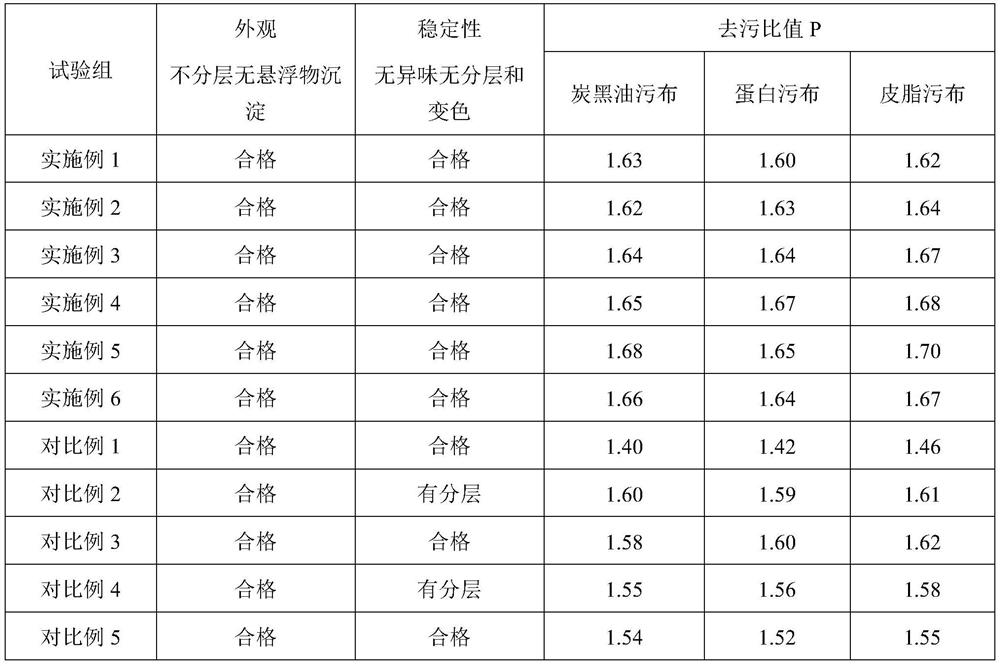

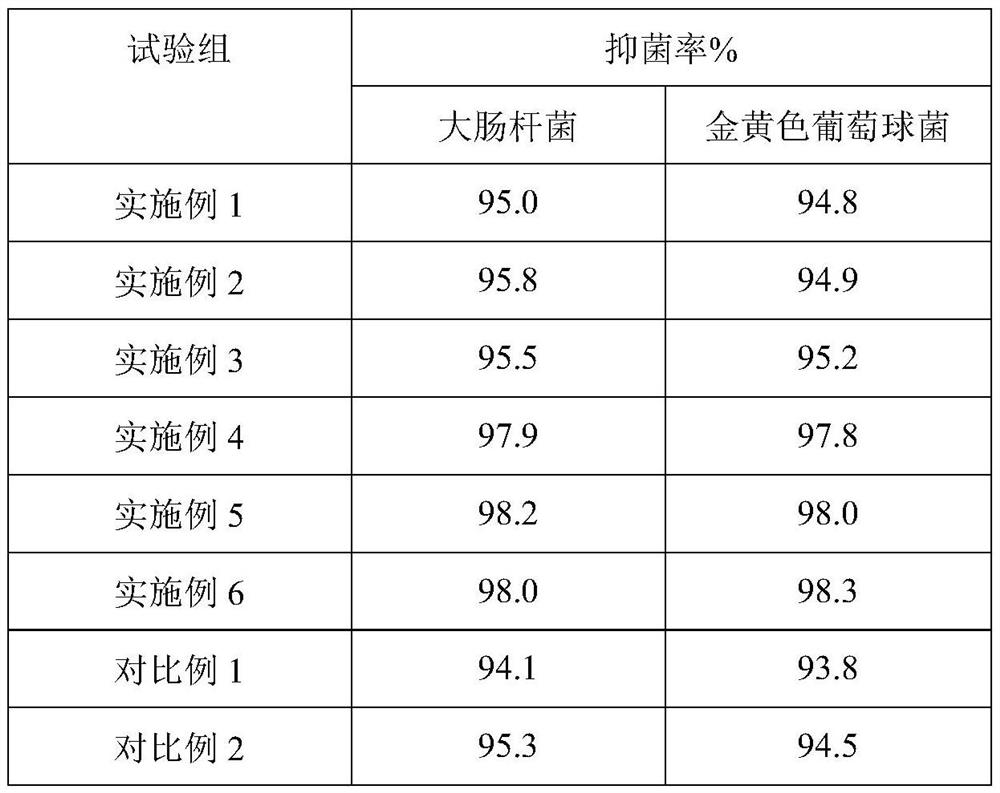

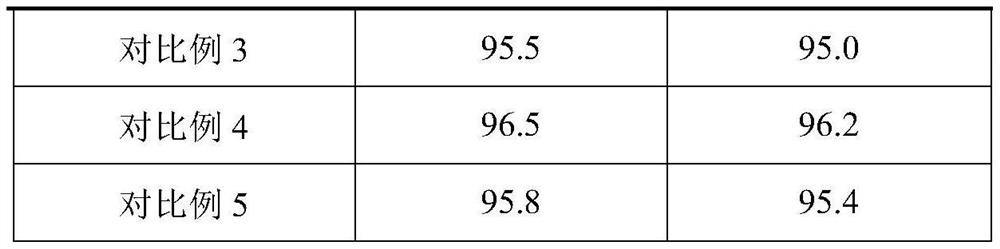

Examples

Embodiment 1

[0023] An antibacterial laundry detergent comprises the following components in parts by weight: 100 parts of deionized water, 0.1 part of disodium edetate, 6 parts of fatty alcohol polyoxyethylene ether, 30 parts of ethoxylated alkyl sodium sulfate, sulfonate 1 part of acid, 8 parts of sodium hydroxide, 5 parts of citric acid, 1 part of tert-butyl hydroquinone, 10 parts of sucrose fatty acid ester, 0.01 part of silver ion antibacterial agent, 0.1 part of Cathone, and 0.1 part of essence.

[0024] S1, adding tert-butyl hydroquinone into sucrose fatty acid ester for emulsification and homogenization to obtain the S1 mixture;

[0025] S2, the S2 mixture of disodium edetate and deionized water are stirred and mixed;

[0026] S3, adding fatty alcohol polyoxyethylene ether, sodium ethoxylated alkyl sulfate, and sodium hydroxide into the S2 mixture and stirring evenly to obtain the S3 mixture;

[0027] S4. Stir the S1 mixture and the S3 mixture evenly, and then add other components...

Embodiment 2

[0029] An antibacterial laundry detergent comprises the following components in parts by weight: 120 parts of deionized water, 0.2 parts of disodium edetate, 8 parts of fatty alcohol polyoxyethylene ether, 35 parts of ethoxylated alkyl sodium sulfate, sulfonate 5 parts of acid, 12 parts of sodium hydroxide, 8 parts of citric acid, 2 parts of tert-butyl hydroquinone, 20 parts of sucrose fatty acid ester, 0.05 part of silver ion bacteriostatic agent, 0.3 part of Cathone, and 0.5 part of essence. The preparation method is the same as in Example 1.

Embodiment 3

[0031] An antibacterial laundry detergent comprises the following components in parts by weight: 110 parts of deionized water, 0.15 parts of disodium edetate, 7 parts of fatty alcohol polyoxyethylene ether, 32 parts of ethoxylated alkyl sodium sulfate, sulfonate 3 parts of acid, 10 parts of sodium hydroxide, 6 parts of citric acid, 1.5 parts of tertiary butyl hydroquinone, 15 parts of sucrose fatty acid ester, 0.03 parts of silver ion antibacterial agent, 0.2 parts of Cathone, and 0.3 parts of essence. The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com