Clean vanadium extraction method and system for vanadium-containing material

A material and clean technology, applied in the field of vanadium extraction system, clean vanadium-containing materials, can solve the problems of ammonium salt waste, poor working environment, low product purity, etc., to improve reaction efficiency, avoid difficult temperature control, and reduce reaction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

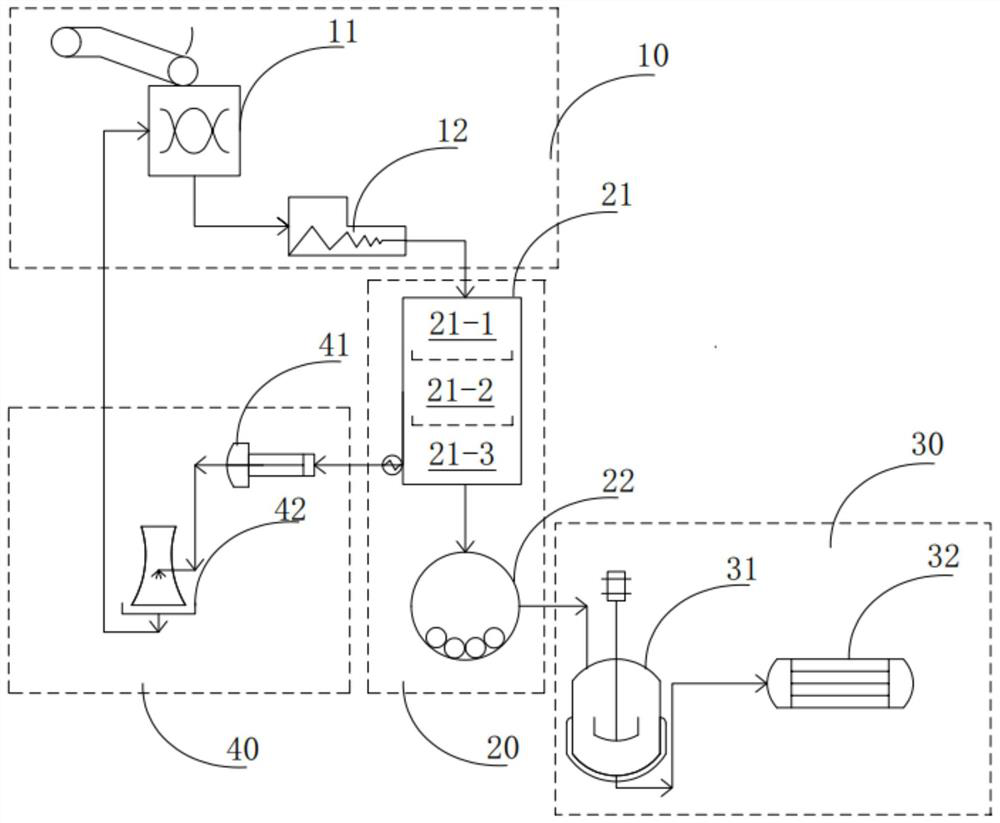

Image

Examples

no. 1 example

[0044] As a first embodiment, it specifically includes the following steps:

[0045] S1: Take vanadium slag and carry out blank roasting under high temperature conditions to obtain V-containing 2 o 5 Vanadium-containing material, the vanadium-containing material obtained after blank roasting, ammonia water and ammonium bicarbonate with a mass concentration of 20% are mixed uniformly in the mixing device at a ratio of 100:15:3.3, and then enter the granulation device for granulation. Control the particle diameter to 13 mm to obtain the ammonification-deammoniation raw material.

[0046] S2: The obtained ammonification-deamination raw material enters the ammonization area of the ammonization-deamination reaction device, reacts in the ammonization area at a constant temperature of 35°C for 70 minutes, then enters the drying area, and dries in the drying area at a constant temperature of 60°C for 48 minutes Then enter the deamination area, react in the deamination area at a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com