Degradable Zn-Li-X series alloy wire and preparation method thereof

An alloy wire and wire technology, which is applied in the field of degradable Zn-Li-X alloy wire and its preparation, can solve the problems of low performance of as-cast zinc alloy and poor comprehensive mechanical properties of pure zinc, and achieve high tensile strength. Strength, excellent plasticity, and the effect of meeting the requirements of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

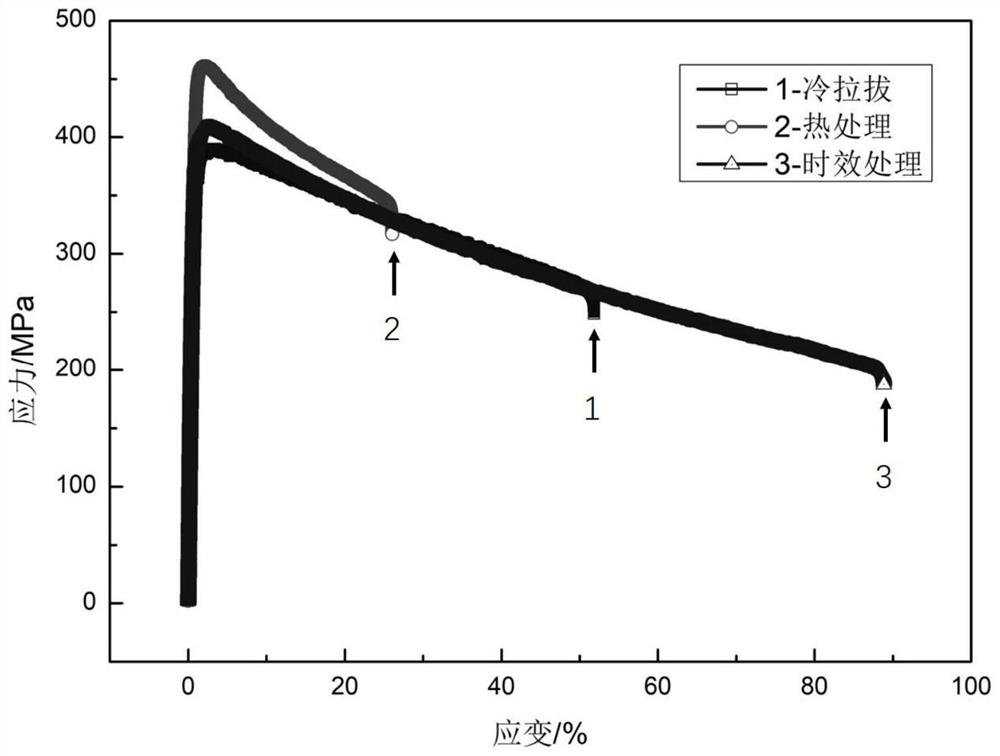

[0024] A degradable Zn-1Li-1Mn alloy wire, Li is 1wt.%, Mn is 1wt.%, and the rest is Zn.

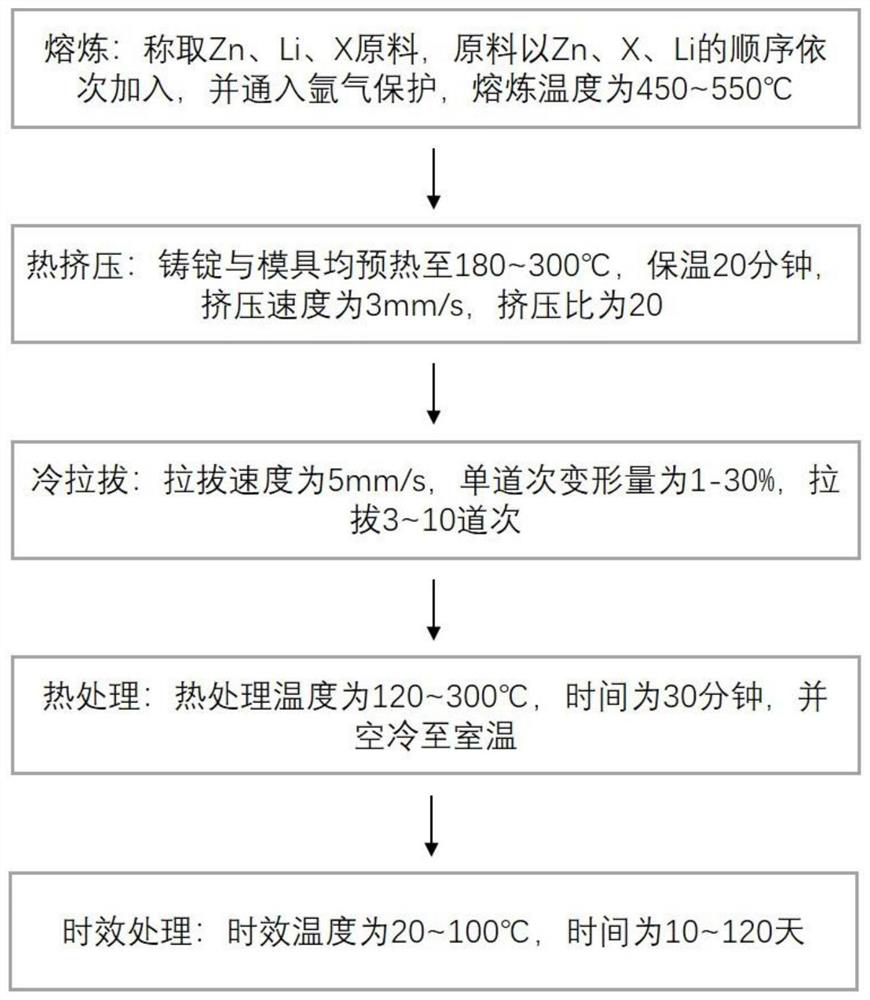

[0025] A preparation method of degradable Zn-1Li-1Mn alloy wire, the specific preparation steps are as follows:

[0026] (1) Take Zn, Li, Mn raw materials according to alloy specific gravity, and carry out atmosphere protection smelting, obtain zinc alloy ingot after casting, cooling;

[0027] (2) hot-extruding the zinc alloy ingot, preheating the ingot and the mold to 200° C., keeping it warm for 20 minutes, the extrusion speed is 3 mm / s, and the extrusion ratio is 20 to obtain a zinc alloy bar;

[0028] (3) The zinc alloy rod is subjected to room temperature cold drawing processing, the drawing speed is 5mm / s, the single-pass deformation is 20%, and the drawing is performed 10 times to obtain the zinc alloy wire;

[0029] (4) Carrying out heat treatment to the zinc alloy wire, the heat treatment temperature is 120° C., the time is 30 minutes, and air-cooled to room temperature;

[00...

Embodiment 2

[0033] A degradable Zn-0.1Li-0.1Mg alloy wire, Li is 0.1wt.%, Mg is 0.1wt.%, and the rest is Zn.

[0034] A preparation method of degradable Zn-0.1Li-0.1Mg alloy wire, the specific preparation steps are as follows:

[0035] (1) Weighing Zn, Li, Mg raw materials according to the specific gravity of the alloy, and carrying out atmosphere protection smelting, casting and cooling to obtain zinc alloy ingots;

[0036] (2) hot-extruding the zinc alloy ingot, preheating the ingot and the mold to 300°C, keeping the temperature for 20 minutes, the extrusion speed is 3mm / s, and the extrusion ratio is 20 to obtain the zinc alloy bar;

[0037] (3) The zinc alloy rod is subjected to room temperature cold drawing processing, the drawing speed is 5mm / s, the single-pass deformation is 1%, and the drawing is 3 passes to obtain the zinc alloy wire;

[0038] (4) Carrying out heat treatment to the zinc alloy wire, the heat treatment temperature is 300° C., the time is 30 minutes, and air-cooled ...

Embodiment 3

[0042] A degradable Zn-0.5Li-5Cu alloy wire, Li is 0.5wt.%, Cu is 5wt.%, and the rest is Zn.

[0043] A preparation method of degradable Zn-0.5Li-5Cu alloy wire, the specific preparation steps are as follows:

[0044] (1) Take Zn, Li, Cu raw material according to alloy specific gravity, and carry out atmosphere protection smelting, obtain zinc alloy ingot after casting, cooling;

[0045] (2) hot-extruding the zinc alloy ingot, preheating the ingot and the mold to 230° C., keeping the temperature for 20 minutes, the extrusion speed is 3 mm / s, and the extrusion ratio is 20 to obtain the zinc alloy bar;

[0046] (3) The zinc alloy bar is subjected to room temperature cold drawing processing, the drawing speed is 5mm / s, the single-pass deformation is 30%, and the drawing is performed 10 times to obtain the zinc alloy wire;

[0047] (4) Carrying out heat treatment to the zinc alloy wire, the heat treatment temperature is 200° C., the time is 30 minutes, and air-cooled to room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com