Shape memory composite material connecting device

A composite material and connecting device technology, applied in the direction of rod connection, connecting components, fixing devices, etc., can solve the problems of reduced structural bearing capacity, poor reliability and stability, and large environmental impact, and achieve simple assembly and disassembly processes. High reliability and good connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

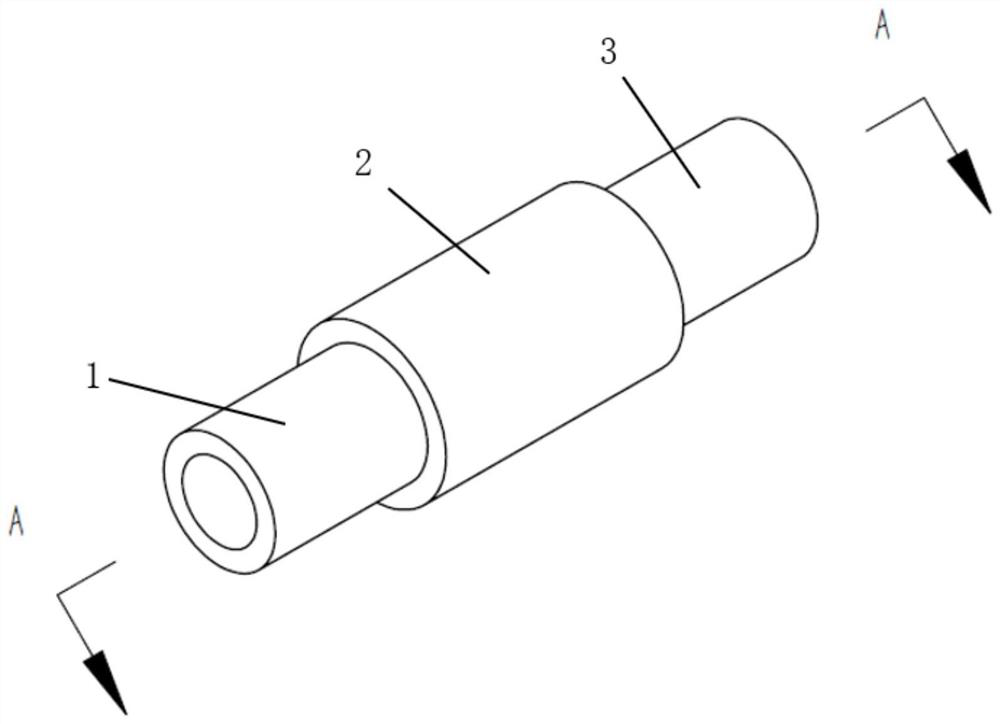

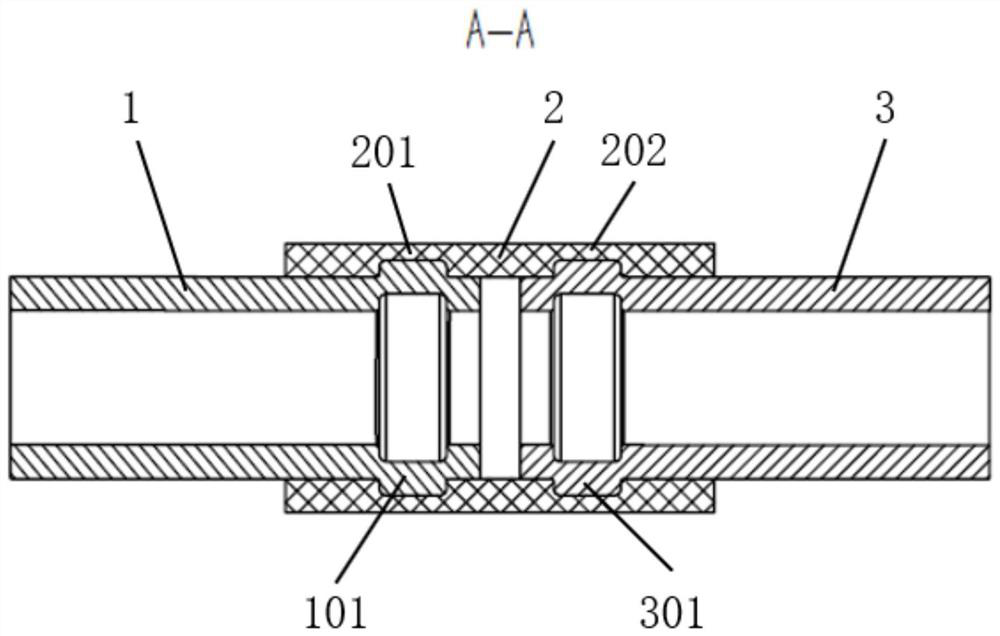

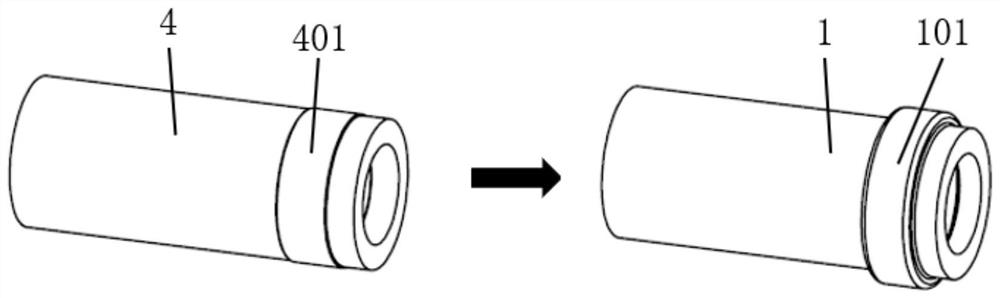

[0027] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in further detail:

[0028] as attached Figure 1-4 As shown, a shape memory composite connecting device of the present invention includes: a first connecting pipe 1, a joint 2, a second connecting pipe 3, a boss 101 of the first connecting pipe, a first groove 201 of the joint, and a first groove 201 of the joint. Two grooves 202, the second connecting pipe boss 301, the heated form 4 of the first connecting pipe, the protruding locking ring 401 of the first connecting pipe, the heated form 5 of the second connecting pipe, the shape of the second connecting pipe Protruding locking ring 501, heating electrode 6; the relationship and working principle between them are: the first connecting pipe boss 101 is located at the end of the first connecting pipe 1, and the second connecting pipe boss 301 is located at the end of the second connecting pipe 3; the first groove 201 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com