Dry-wet alternating ultraviolet irradiation simulation corrosion test device

A dry-wet alternation, corrosion test technology, used in weather resistance/light resistance/corrosion resistance, measuring devices, cleaning hollow objects, etc. The effect of high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

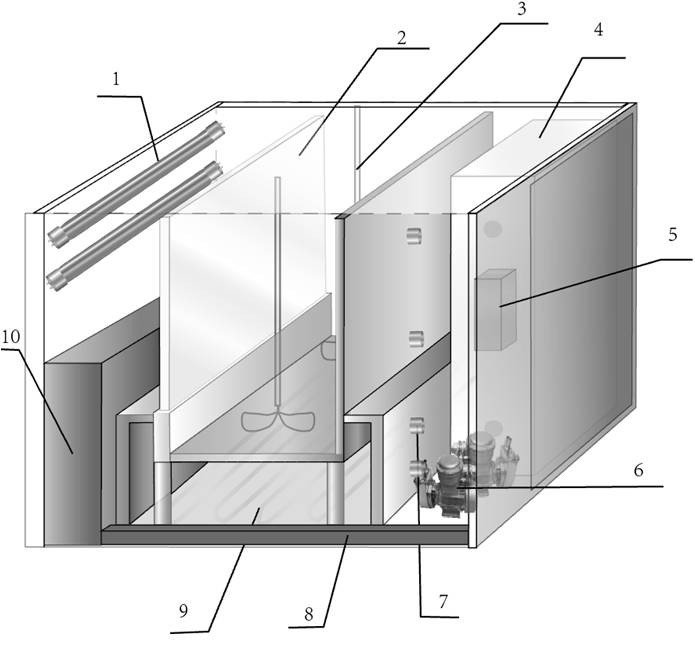

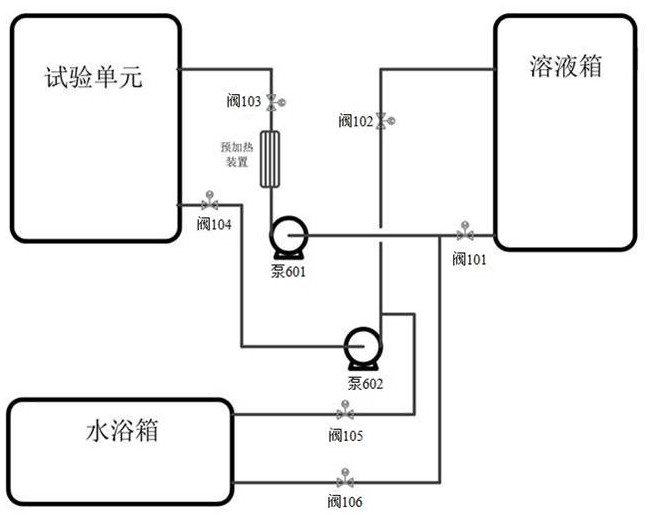

[0026] Combine below figure 1 and figure 2 The following is a detailed description of a dry-wet alternating ultraviolet light simulating corrosion test device of the present invention.

[0027] Such as figure 1 As shown, a dry-wet alternating ultraviolet light simulation corrosion test device of the present invention, its main structure includes a test unit, a solution tank 4, a water bath tank and a water circulation control pipeline system, and one side of the test box in the test unit adopts a transparent The transparent quartz glass 2 with good light is used as the wall plate, which can ensure the required light transmission while isolating the ultraviolet lamp tube 1 from the test environment. The ultraviolet lamp tube 1 and the automatic control system 10 are installed on the glass wall plate outside the test chamber One side; the stirring wave-making device 3 is installed in the test chamber, and the clamping of the test sample is an ordinary detachable sample holder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com