High-temperature-resistant membrane material for vacuum heat insulation plate and vacuum heat insulation composite plate

A technology of vacuum insulation panels and high temperature resistant films, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of long-term exposure to 70 degrees, achieve the expansion of market application fields, good heat resistance , good barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

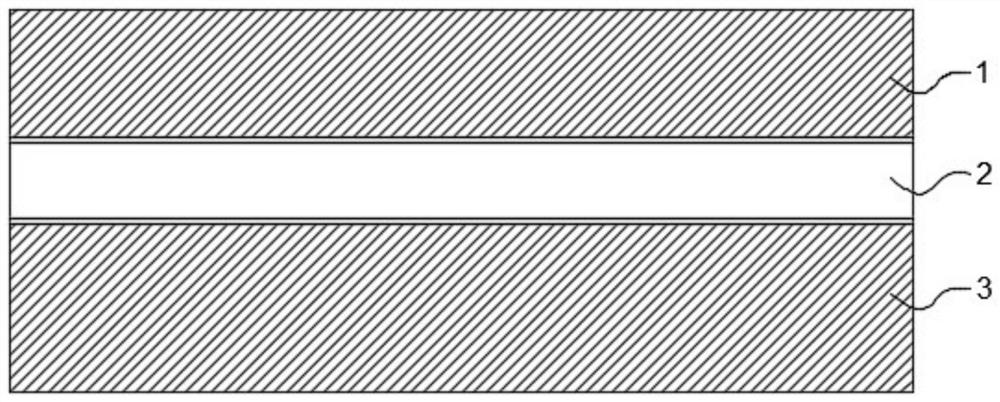

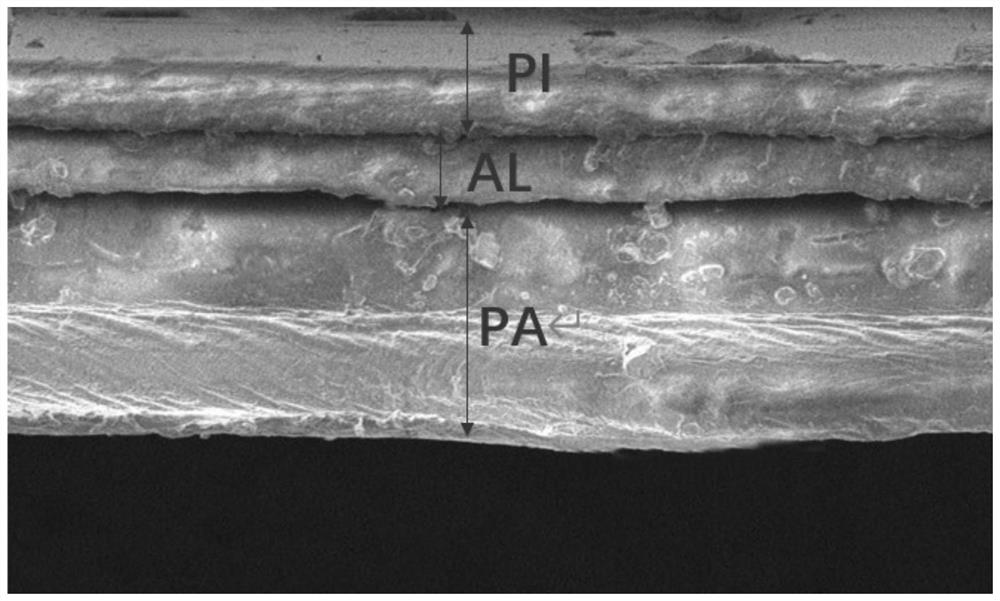

[0028] see figure 1 , In the figure, 1 is a polyimide film layer, 2 is an aluminum foil layer, and 3 is a polyamide film layer. A high-temperature-resistant film material for a vacuum heat-insulation panel is used for wrapping a vacuum heat-insulation panel and used as an outer film of the vacuum heat-insulation panel to improve the high-temperature resistance performance of the vacuum heat-insulation panel. In this embodiment, the high-temperature-resistant film material includes a protective layer, a metal layer and a heat-sealing layer stacked in sequence, forming a multi-layer film structure. The insulation layer is made of polyimide film, and the side away from the metal layer is bright yellow, which plays the role of high temperature and high humidity resistance. In this embodiment, the thickness of the protective layer is 25 μm. The metal layer is made of aluminum foil, and the thickness of the metal layer can be between 7-9 μm. In this embodiment, the thickness of the...

Embodiment 2

[0048] Please combine Figure 5 , this embodiment discloses a vacuum insulation composite panel, including a vacuum insulation panel and a high-temperature-resistant film material wrapped outside the vacuum insulation panel; the high-temperature-resistant film material uses the high-temperature-resistant film for vacuum insulation panels in Example 1 material. In the figure, B is a vacuum insulation panel, and M is a high temperature resistant membrane material.

[0049]In this embodiment, the performance test of the prepared vacuum heat insulation composite board is also carried out, and at the same time, conventional boards on the market are used as a comparison. details as follows.

[0050] c. Thermal conductivity test

[0051] Comparison test under normal temperature conditions, the test results are shown in Table 3.

[0052] Table 3 is the test results of thermal conductivity at room temperature.

[0053]

[0054]

[0055] 200-degree condition comparison test, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com