Down-hole impact high-pressure jet grouting composite pile forming method

A high-pressure rotary grouting pile and high-pressure rotary grouting technology are applied in the direction of sheet pile walls, soil protection, construction, etc., which can solve problems such as delay in construction period, short construction period, and high rate of pile breakage of inclined piles, so as to ensure the depth of rock-socketed, Improve the strength of the soil between the piles and the effect of increasing the bearing capacity of the single pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Select high-quality R42.5# ordinary silicon cement, and calibrate the maximum water level line according to the size of the mixing tank, water-cement ratio, and mud specific gravity. Add cement according to the water-cement ratio of 1:1, and stir thoroughly to determine whether the specific gravity of the mud reaches the trial proportion of 1.47. If it cannot reach the proportion, continue to add cement until it reaches the trial proportion of cement slurry. The mixing time cannot exceed the initial setting time of the cement slurry, and it is filtered through two filters to prevent the nozzle from being blocked.

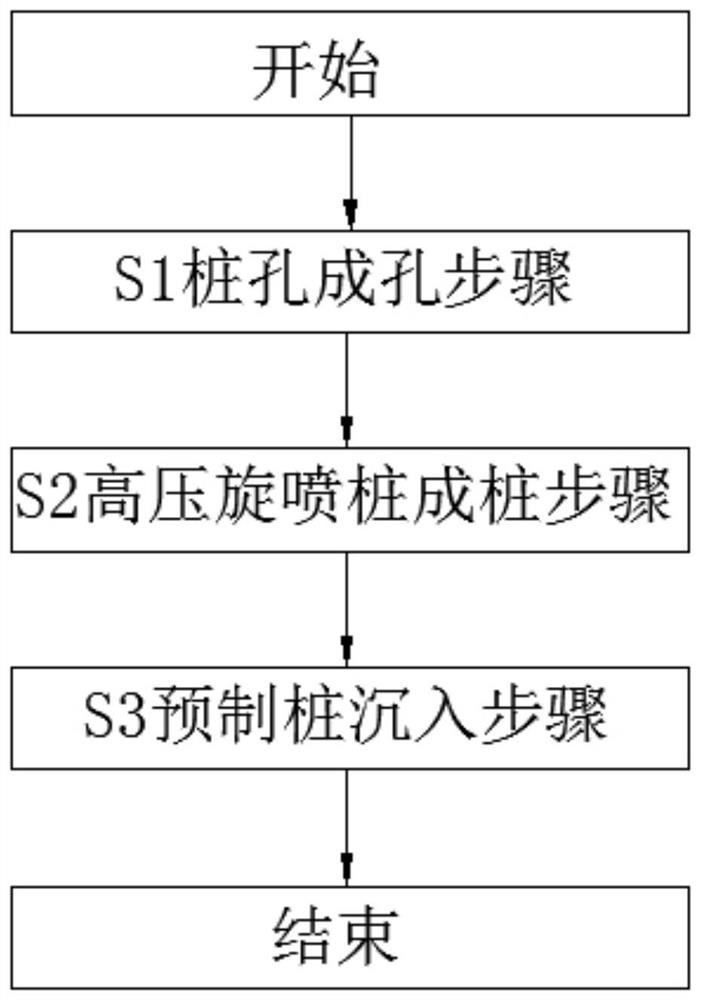

[0029] S1 pile hole forming steps: After the down-the-hole impact high-pressure rotary grouting drilling rig is in place, the deviation of verticality after correction does not exceed ±0.5%, and the down-the-hole hammer is driven by the 20Mpa high-pressure air driven by the impactor at the bottom of the drill pipe. , until the depth reaches the design depth o...

Embodiment 2

[0038] Select high-quality R42.5# ordinary silicon cement, and calibrate the maximum water level line according to the size of the mixing tank, water-cement ratio, and mud specific gravity. Add cement according to the water-cement ratio of 1:1, and stir fully to determine whether the specific gravity of the mud reaches the trial proportion of 1.47. If it cannot reach the proportion, continue to add cement until it reaches the trial proportion of cement slurry. The mixing time cannot exceed the initial setting time of the cement slurry, and it is filtered through two filters to prevent the nozzle from being blocked.

[0039] S1 pile hole forming steps: After the down-the-hole impact high-pressure rotary grouting drilling rig is in place, the deviation of verticality after correction does not exceed ±0.5%, and the down-the-hole hammer is driven by the 20Mpa high-pressure air driven by the impactor at the bottom of the drill pipe. , until the depth reaches the design depth of 10m...

Embodiment 3

[0047] Select high-quality R42.5# ordinary silicon cement, and calibrate the maximum water level line according to the size of the mixing tank, water-cement ratio, and mud specific gravity. Add cement according to the water-cement ratio of 1:1, and stir thoroughly to determine whether the specific gravity of the mud reaches the trial proportion of 1.47. If it cannot reach the proportion, continue to add cement until it reaches the trial proportion of cement slurry. The mixing time cannot exceed the initial setting time of the cement slurry, and it is filtered through two filters to prevent the nozzle from being blocked.

[0048] S1 pile hole forming steps: After the down-the-hole impact high-pressure rotary grouting drilling rig is in place, the deviation of verticality after correction does not exceed ±0.5%, and the down-the-hole hammer is driven by the 25Mpa high-pressure air driven by the impactor at the bottom of the drill pipe. , until the depth reaches the design depth o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com