Method for controlling surface lines of high-end beverage cans

A control method and beverage can technology, applied in the field of steel rolling, to achieve the effect of solving the rough surface texture of high-end beverage cans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

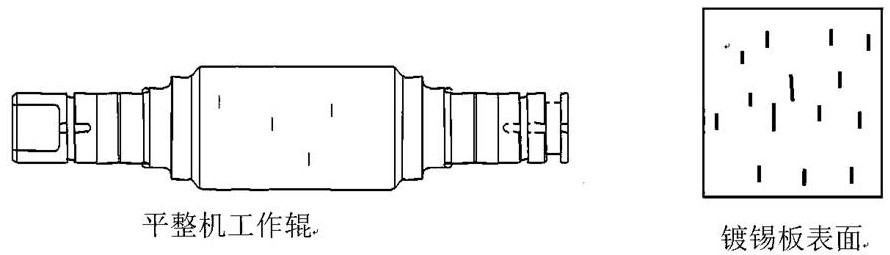

[0016] This embodiment provides a method for controlling the surface texture of a high-end beverage can. The tin-plated plate is poured into a leveling machine, and by using double racks, the two racks use work rolls with different processing methods and roughness to control the The surface texture of the tin-plated plate ensures that the surface of the produced steel coil meets the requirements.

[0017] Adjust the working parameters of the leveling machine during production as follows:

[0018] (1) Technological requirements for work roll matching of levelling machine:

[0019] 1# Frame leveling work roll: EDM texturing roll is adopted, and the roughness Ra is controlled at 1.45±0.05μm;

[0020] 2# Frame leveling work roll: using grinding smooth roll, the roughness Ra is controlled at 0.45±0.04;

[0021] (2) Grinding process requirements for levelling smooth rollers for levelling machines:

[0022] A 120-mesh particle size grinding wheel is used, and the particle size is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com