Intermittent asphalt concrete mixing plant

A technology of asphalt concrete and mixing plant, which is applied in the direction of cement mixing device, clay preparation device, mixing operation control, etc. It can solve the problems of high temperature of hot aggregate, affecting the production quality of asphalt concrete, environmental pollution, etc., and achieve energy saving, The effect of lowering the temperature and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

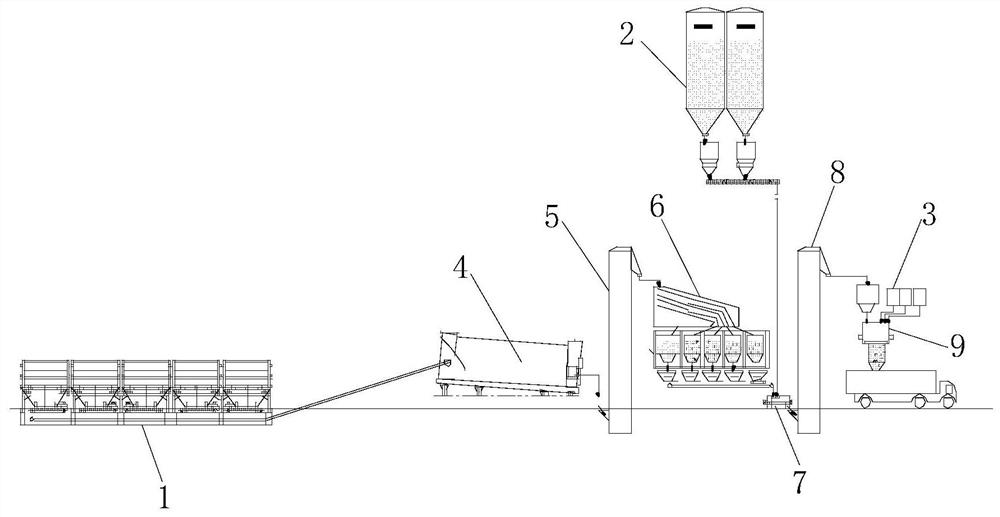

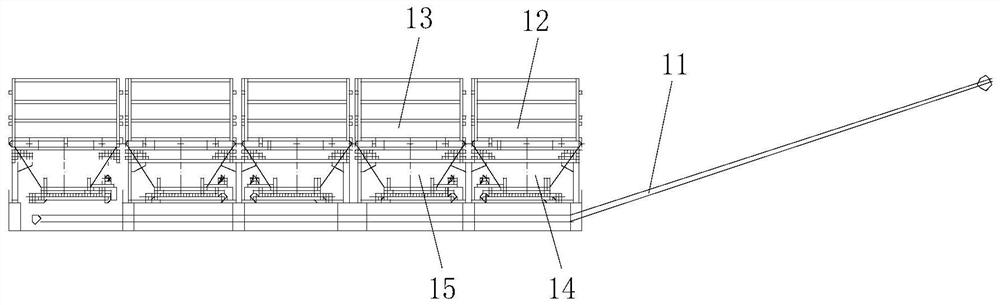

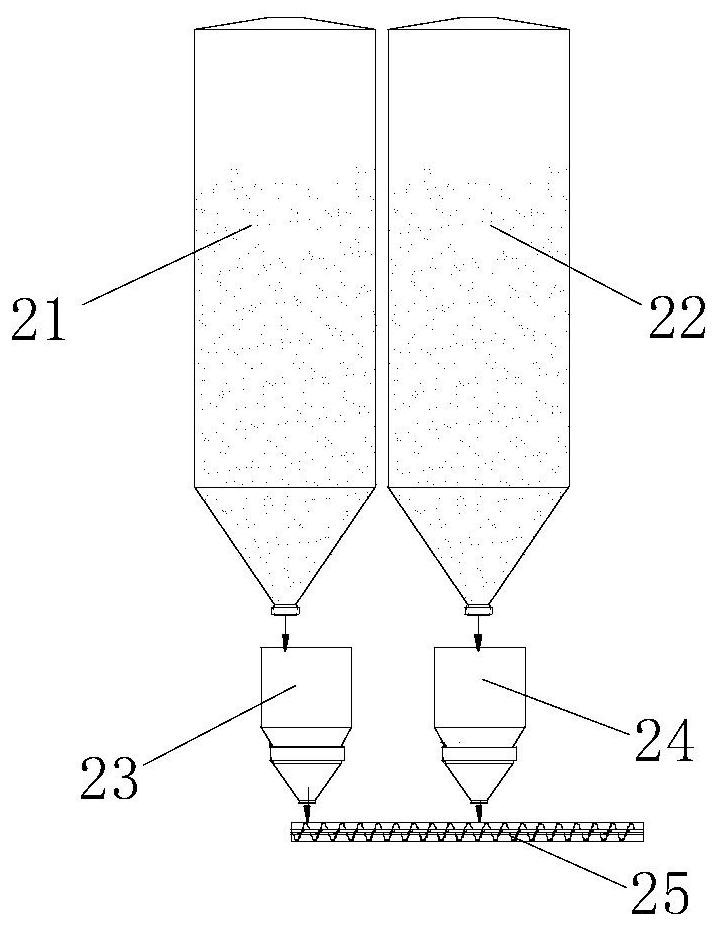

[0028] Such as Figure 1-Figure 5 As shown, this embodiment provides a batch asphalt concrete mixing plant, including but not limited to an aggregate feeding device 1, a powder feeding device 2, an asphalt feeding device 3, a drying device 4, and a first transfer device 5. Screening device 6, premixing device 7, second transfer device 8 and stirring and mixing device 9, the aggregate feeding device 1 is used to provide aggregates for the production of asphalt concrete for the mixing station, and the powder feeding device 2 is used for The powder material for producing asphalt concrete is provided for the mixing station, and the asphalt feeding device 3 is used for providing the asphalt for producing asphalt concrete for the mixing station.

[0029] The aggregate feeding device 1, the drying device 4, the first transfer device 5 and the screening device 6 are sequentially connected, and the aggregate of the aggregate feeding device 1 is dried by the drying device 4, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com