Preparation method of special antirust agent for crawler belt

A technology of anti-rust agent and track, which is applied in the direction of anti-corrosion coatings, coatings, polyurea/polyurethane coatings, etc., and can solve problems such as cracking of the anti-rust agent layer, inability to provide long-term and comprehensive protection, and decline in the protective effect of the anti-rust agent , to achieve the effect of improving film-forming strength, excellent elasticity, and good flex resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

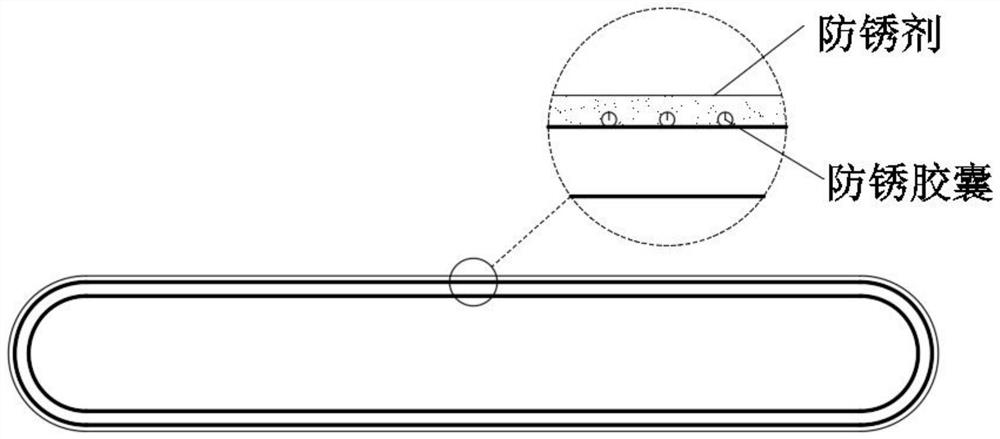

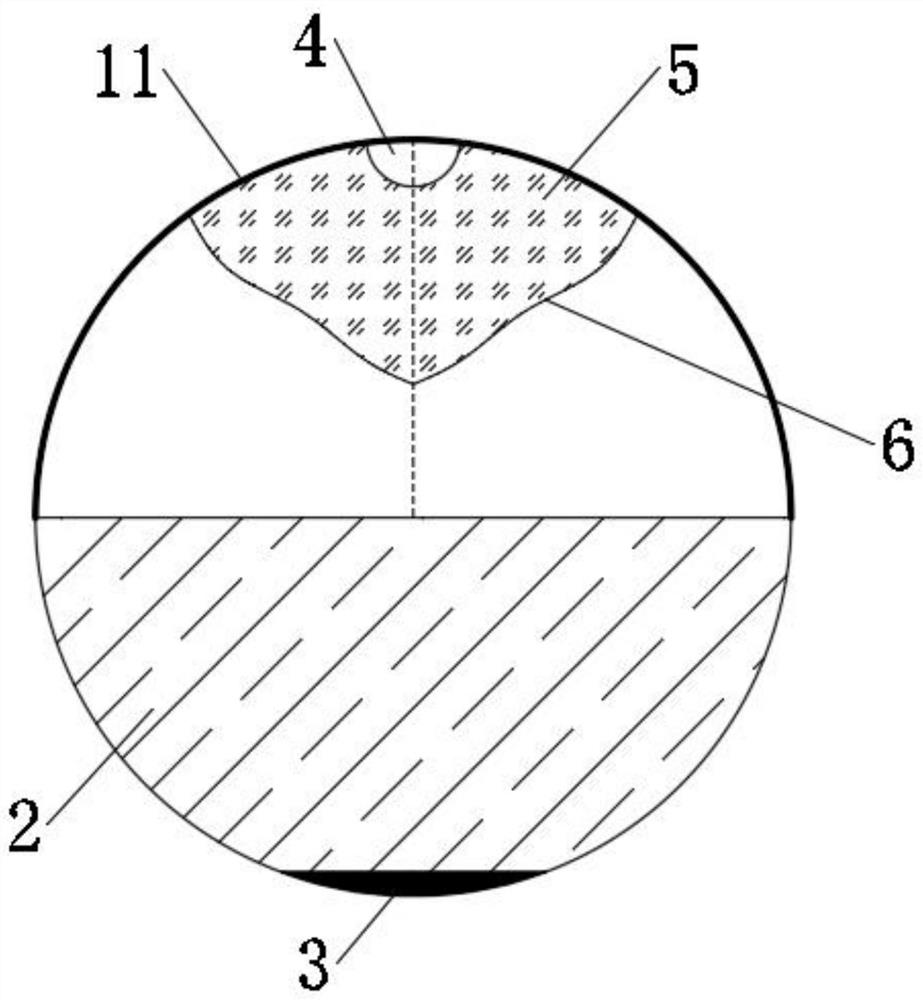

[0044] see figure 1 , a preparation method of special antirust agent for crawler tracks, comprising the following steps:

[0045] S1, the following raw materials are taken in parts by weight: 5 parts of ammonium benzoate, 3 parts of benzotriazole, 8 parts of sodium dodecylsulfonate, 70 parts of butadiene copolymer, 8 parts of calcium stearate and stearic acid 6 parts of aluminum, after high temperature and high humidity mixing, the antirust agent is obtained after mixing in a twin-screw extruder;

[0046] S2. Take 56 parts of solvent-based polyurethane adhesives and 32 parts of solvent oil in parts by weight to obtain a semi-fluid mixture;

[0047] S3. After fully mixing 12 parts of the antirust agent in S1 with 88 parts of the semi-fluid mixture in S2, the finished antirust agent is obtained after filtering the residual solidified particles;

[0048] S4. A plurality of anti-rust capsules are uniformly adsorbed on the track through the magnetic field, and distributed along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com