An impact-resistant and wear-resistant composite liner and its preparation method

A technology of anti-impact and wear-resistant, composite liner, which is applied in the field of wear-resistant materials, can solve the problems of poor impact resistance and poor toughness, and achieve the effects of good combination, improved damage tolerance, and improved wear resistance of the liner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of an impact-resistant and wear-resistant composite liner comprises the following steps:

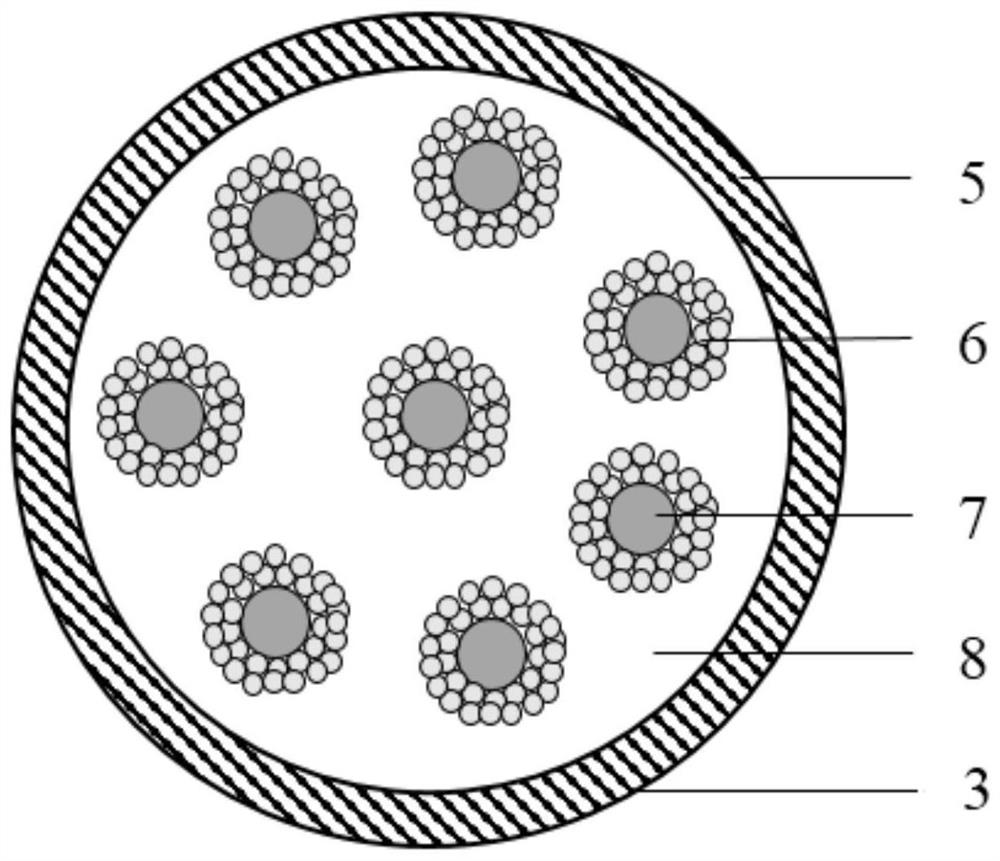

[0034] Step 1, roll the H08A low carbon steel strip with a width of 5mm and a thickness of 0.08mm into a U-shaped steel strip, mix Ta wire, iron powder and graphite powder evenly, then put the mixture into the U-shaped steel strip, and then put the U-shaped steel strip Steel strip encapsulation and rolling to obtain metal fibers with an outer diameter of 1 mm;

[0035] The mass percentage of Ta wire in the mixture is 82.7%, the mass percentage of iron powder is 12%, and the mass percentage of graphite powder is 5.3%; 5μm;

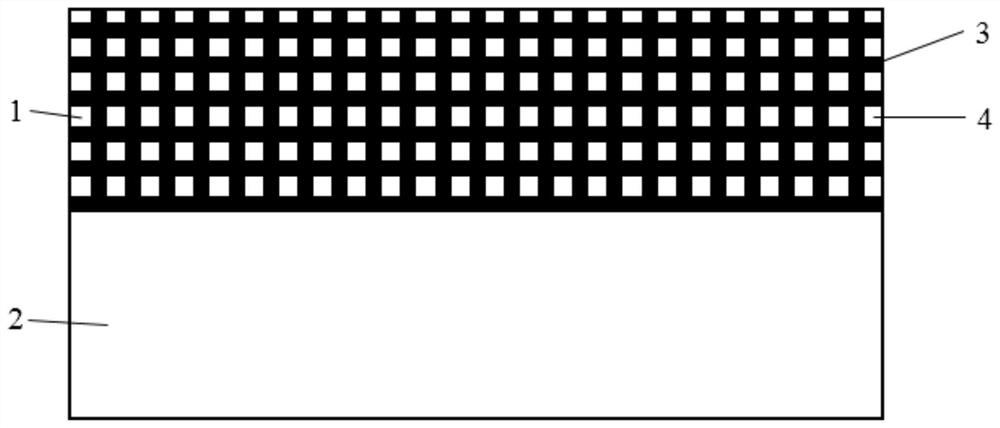

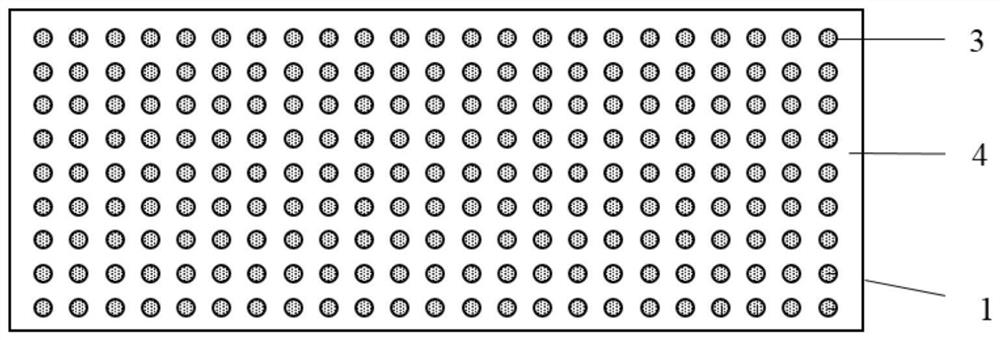

[0036] Step 2, weave the metal fibers prepared in step 1 into a fiber mesh prefabricated body, and the distance between the fibrous reinforcements in the thickness direction d 1 = 3mm, distance d between transverse fibrous reinforcements 2 = 2mm, longitudinal fibrous reinforcement spacing d 3 = 2mm;

[0037] Step 3, using an intermediate fr...

Embodiment 2

[0050] The preparation of an impact-resistant and wear-resistant composite liner comprises the following steps:

[0051] Step 1, roll the H08A low carbon steel strip with a width of 4mm and a thickness of 0.06mm into a U-shaped steel strip, mix Ti wire, iron powder and graphite powder evenly, then put the mixture into the U-shaped steel strip, and then put the U-shaped steel strip Steel strip encapsulation and rolling to obtain metal fibers with an outer diameter of 1.5mm;

[0052] The mass percentage of Ti wire in the mixture is 60.1%, the mass percentage of iron powder is 28.9%, and the mass percentage of graphite powder is 11%; 5μm;

[0053] Step 2, weave the metal fibers prepared in step 1 into a fiber mesh prefabricated body, and the distance between the fibrous reinforcements in the thickness direction d 1 = 3mm, distance d between transverse fibrous reinforcements 2 = 2mm, longitudinal fibrous reinforcement spacing d 3 = 2mm;

[0054] Step 3, using an intermediate ...

Embodiment 3

[0066] The preparation of an impact-resistant and wear-resistant composite liner comprises the following steps:

[0067] Step 1, roll the H08A low carbon steel strip with a width of 6mm and a thickness of 0.1mm into a U-shaped steel strip, mix Nb wire, iron powder and graphite powder evenly, then put the mixture into the U-shaped steel strip, and then put the U-shaped steel strip Steel strip encapsulation and rolling to obtain metal fibers with an outer diameter of 2mm;

[0068] The mass percentage of Nb wire in the mixture is 72.5%, the mass percentage of iron powder is 18.8%, and the mass percentage of graphite powder is 8.7%; 5μm;

[0069] Step 2, weave the metal fibers prepared in step 1 into a fiber mesh prefabricated body, and the distance between the fibrous reinforcements in the thickness direction d 1 = 3mm, distance d between transverse fibrous reinforcements 2 = 3mm, longitudinal fibrous reinforcement spacing d 3 = 3mm;

[0070] Step 3, using an intermediate fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com