Coating of copper-based surface intermetallic compound reinforced gradient high-entropy alloy and preparation method

A high-entropy alloy and surface metal technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of complex and tedious overall process, high brittleness, insufficient coating toughness, etc., to save production cost, strengthen hardness, reduce The effect of ductile-brittle transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

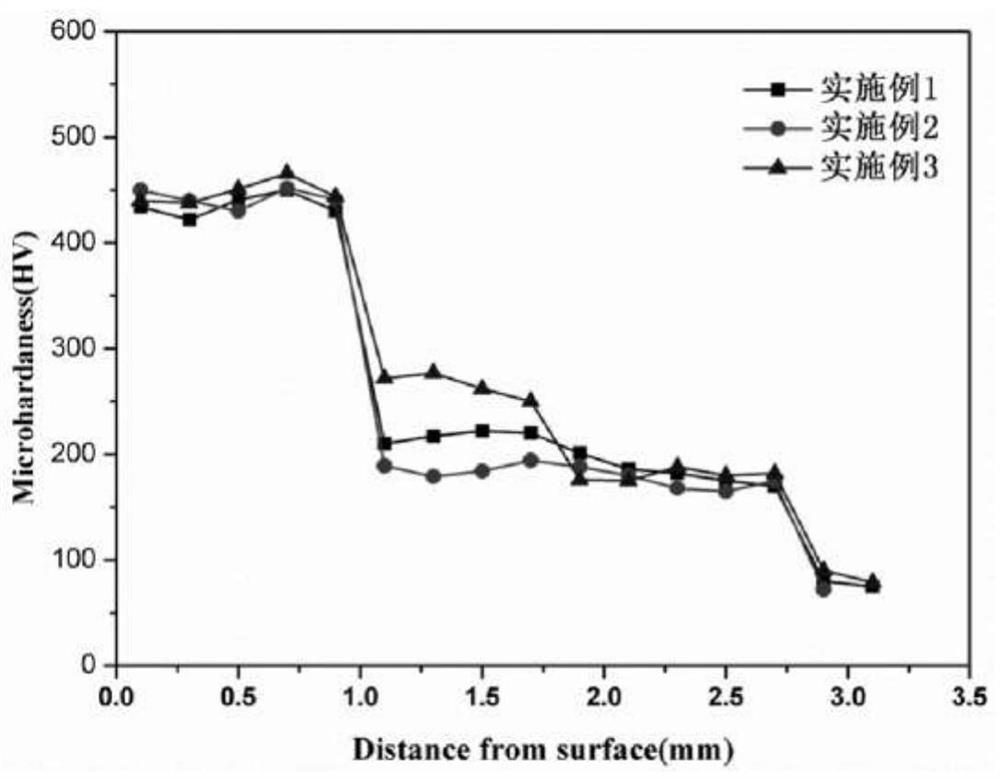

Embodiment 1

[0042] a formulated alloy powder, select CO, Cr, Fe, Ni, Al, Ti element powder to 1: 1: 1: 1: 1: X: Y (0 <x ≤ 1, 0 <y ≤ 1) atom is evenly uniform Mix; the purity of the metal powder is greater than 99.5%, the particle size is 100 ~ 300 mesh;

[0043] The B mixed powder is prepared by low energy ball milling. The specific step is: the powder mixed with powder is added to the ball mill, vacuum, and the ball mass ratio is 5: 1, the rotational speed is 150 r / min, the ball milling time is 2 h, will The powder is mixed; the ball mill is a vacuum stainless steel tank, and the ball is used as a stainless steel ball, and the ball mill is not added.

[0044] C is preprocessed on the surface of the T1 copper base. The specific step includes cleaning, drying, drying or sandblasting with # 400 and # 800, with anhydrous ethanol or acetone to clean the surface impurities and oil;

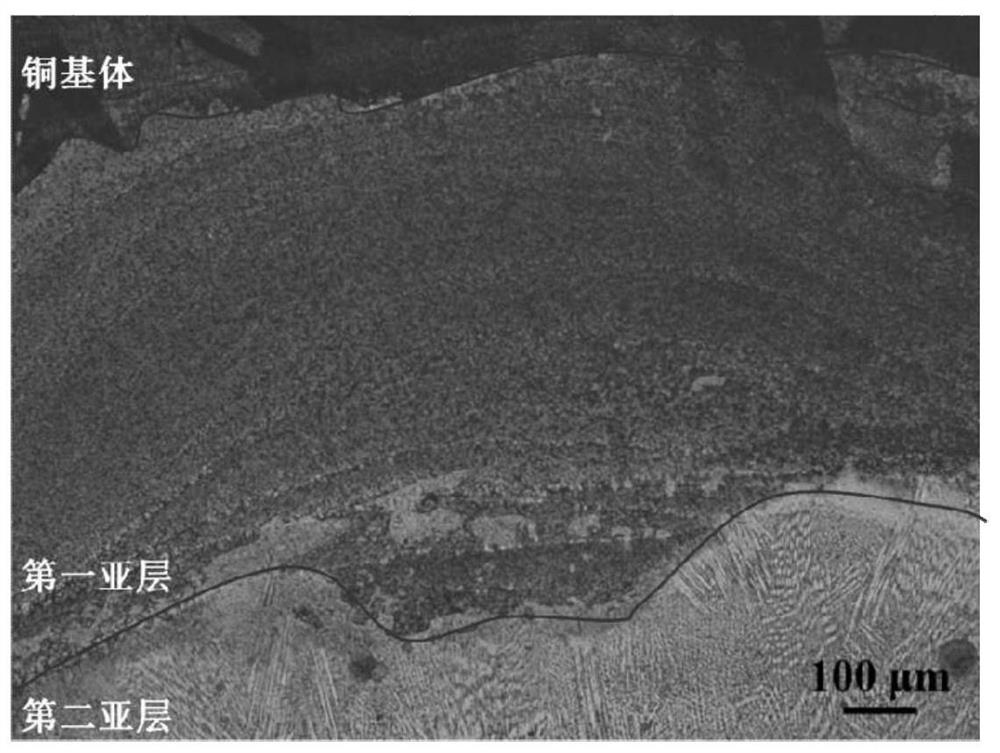

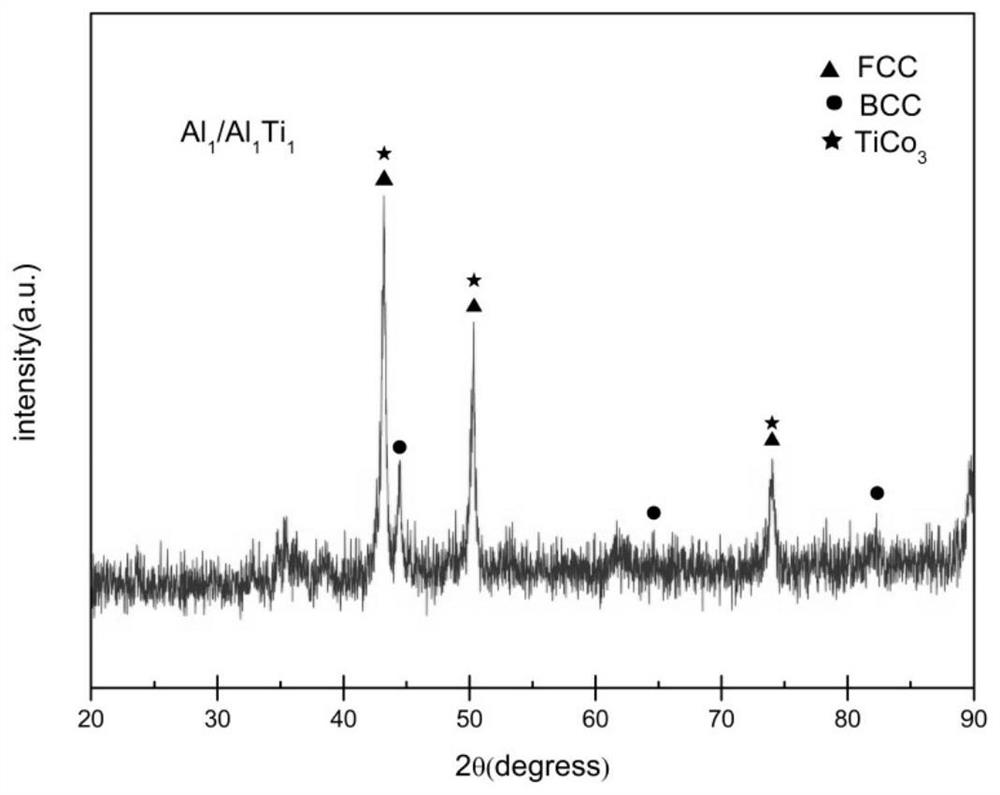

[0045] D From the surface of the matrix, the first sublayer is a CoCrfeni high entropy alloy powder, and the seco...

Embodiment 2

[0051] a formulated alloy powder, use CO, Cr, Fe, Ni, Al, Ti element powder to 1: 1: 1: 1: 1: 0.7: Y (0 <x ≤ 1, 0 <y≤1) atom is evenly uniform Mix; the purity of the metal powder is greater than 99.5%, the particle size is 100 ~ 300 mesh;

[0052] The B mixed powder is prepared by low energy ball milling. The specific step is: the powder mixed with powder is added to the ball mill, vacuum, and the ball mass ratio is 5: 1, the rotational speed is 150 r / min, the ball milling time is 2 h, will The powder is mixed; the ball mill is a vacuum stainless steel tank, and the ball is used as a stainless steel ball, and the ball mill is not added.

[0053] C is preprocessed on the surface of the T1 copper base. The specific step includes cleaning, drying, drying or sandblasting with # 400 and # 800, with anhydrous ethanol or acetone to clean the surface impurities and oil;

[0054] D From the surface of the substrate, the first sublayer is a CoCrfeni high entropy alloy powder, and the seco...

Embodiment 3

[0060] a formulated alloy powder, use CO, Cr, Fe, Ni, Al, Ti element powder to 1: 1: 1: 1: 1: 0.7: Y (0 <x ≤ 1, 0 <y≤1) atom is evenly uniform Mix; the purity of the metal powder is greater than 99.5%, the particle size is 100 ~ 300 mesh;

[0061] The B mixed powder is prepared by low energy ball milling. The specific step is: the powder mixed with powder is added to the ball mill, vacuum, and the ball mass ratio is 5: 1, the rotational speed is 150 r / min, the ball milling time is 2 h, will The powder is mixed; the ball mill is a vacuum stainless steel tank, and the ball is used as a stainless steel ball, and the ball mill is not added.

[0062] C is preprocessed on the surface of the T1 copper base. The specific step includes cleaning, drying, drying or sandblasting with # 400 and # 800, with anhydrous ethanol or acetone to clean the surface impurities and oil;

[0063] D From the surface of the substrate, the first sublayer is a CoCrfeni high entropy alloy powder, and the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com