Layered positive electrode material and preparation method and application thereof

A positive electrode material and layered technology, applied in the field of layered positive electrode materials and their preparation, can solve the problems of increased internal resistance, decreased material performance, and affected material safety performance, etc., and achieves improved conductivity, improved processing performance, and improved electrical Effects of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

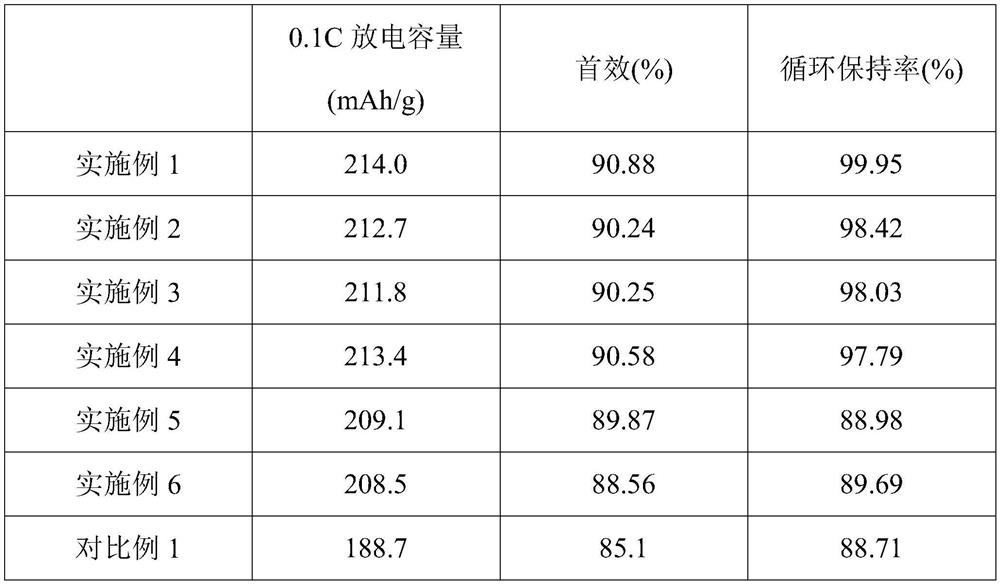

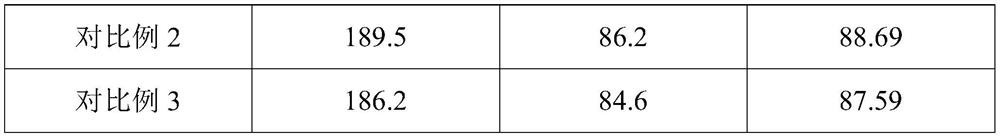

Examples

Embodiment 1

[0042] This embodiment provides a layered positive electrode material, the chemical formula of the layered positive electrode material is Li 1.05 (Ni 0.88 co 0.09 mn 0.03 )O 2 .

[0043] The preparation method of the layered positive electrode material is as follows:

[0044] (1) layered nickel cobalt manganese hydroxide Ni 0.88 co 0.09 mn 0.03 (OH) 2 After mixing evenly with lithium hydroxide at a molar ratio of 1:1.05, sinter once at 900°C for 12 hours in an oxygen atmosphere of 5L / min, cool to room temperature, grind, pulverize and sieve to obtain a sintered product;

[0045] (2) Put the first-fired product described in step (1) into a sagger and put it in an experimental furnace, then feed sulfur dioxide gas with a flow rate of 10 L / min in the experimental furnace, and heat up to 400 °C at a heating rate of 4 ° C / min. °C and then perform secondary sintering for 6 hours to obtain the layered positive electrode material.

Embodiment 2

[0047] The difference between the embodiment and the embodiment 1 is that in the step (1) of the embodiment, the temperature of the primary sintering is 850°C.

[0048] All the other preparation methods and parameters are consistent with Example 1.

Embodiment 3

[0050] This embodiment provides a layered positive electrode material, the chemical formula of the layered positive electrode material is Li 1.02 (Ni 0.5 co 0.2 mn 0.3 )O 2 .

[0051] The preparation method of the layered positive electrode material is as follows:

[0052] (1) layered nickel cobalt manganese hydroxide Ni 0.5 co 0.2 mn 0.3 (OH) 2 After mixing evenly with lithium hydroxide at a molar ratio of 1:1.02, sinter once at 850°C for 18 hours in an oxygen atmosphere of 3L / min, cool to room temperature, grind, pulverize and sieve to obtain a sintered product;

[0053] (2) Put the first-fired product described in step (1) into a sagger and put it in an experimental furnace, then feed sulfur dioxide gas with a flow rate of 5 L / min in the experimental furnace, and heat up to 300 °C at a heating rate of 3 ° C / min. °C and then perform secondary sintering for 8 hours to obtain the layered positive electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com