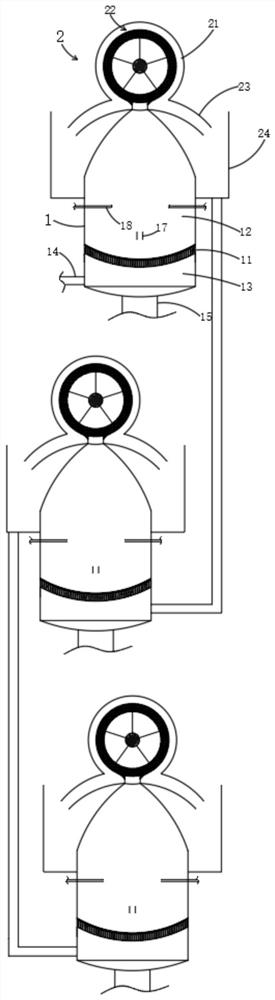

Fluorine-containing industrial wastewater treatment process and final-stage treatment device and process thereof

A technology for industrial wastewater and treatment devices, which is applied in mining wastewater treatment, water/sewage multi-stage treatment, adsorbed water/sewage treatment, etc. problem, to achieve the effect of high utilization rate, improved processing efficiency and effect, and less usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

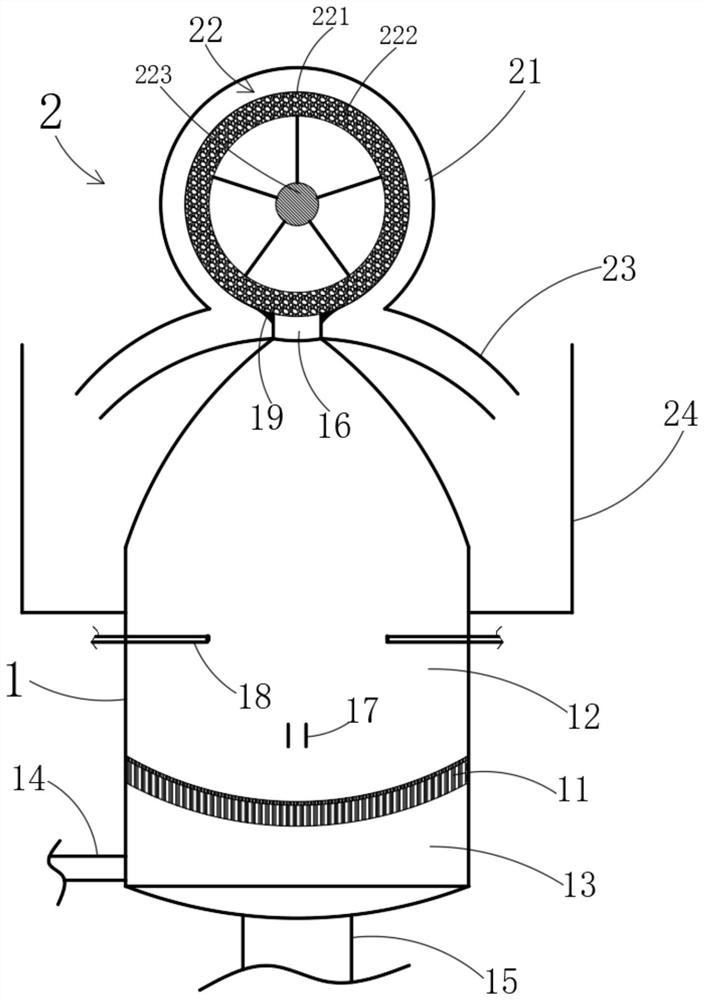

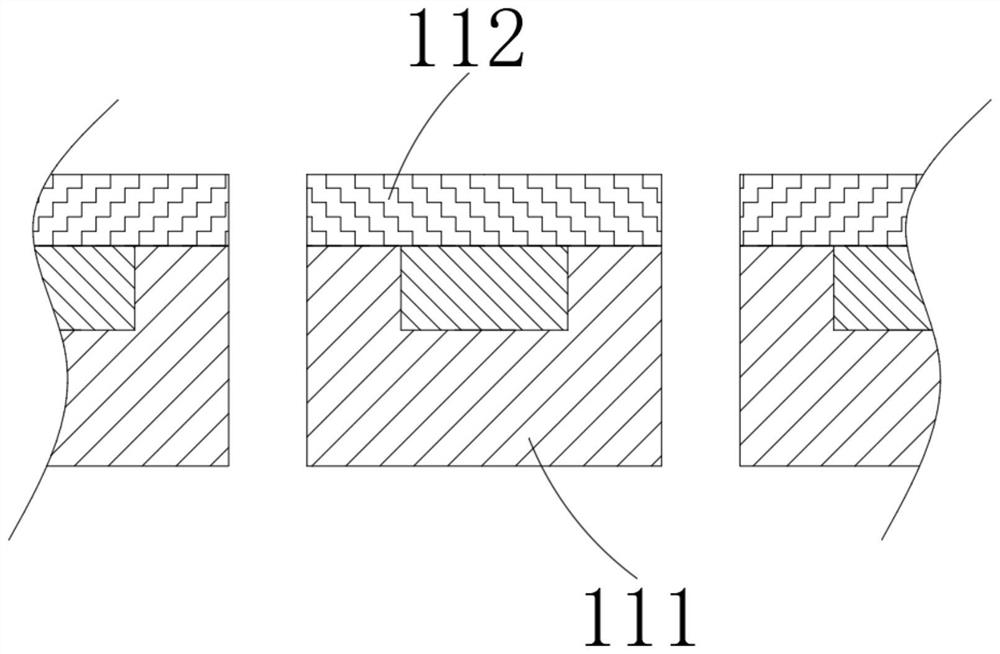

[0040] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0041] A process for treating fluorine-containing industrial wastewater, comprising the following steps:

[0042] ① Adjust the PH value of the sewage to 7-8 through hydrochloric acid or liquid alkali;

[0043] ② Add bleach to oxidize the sewage and reduce the COD value of the sewage;

[0044] ③ Sewage is filtered through lime slurry tank sedimentation to remove fluoride ions and some excess bleaching water;

[0045] ④ Add hydrochloric acid to the filtered sewage liquid to neutralize the precipitate and filter;

[0046] ⑤Pump the re-filtered sewage to the activated carbon adsorption tower, and at the same time inject ozone to start aeration to further reduce the CO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com