System for directionally converting dipeptide through continuous flow membrane enzyme coupling

A directional transformation, flow membrane enzyme technology, applied in the direction of supporting/immobilizing microorganisms, specific-purpose bioreactors/fermenters, biochemical instruments, etc., to increase contact time, increase contact area, and improve conversion rate and yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

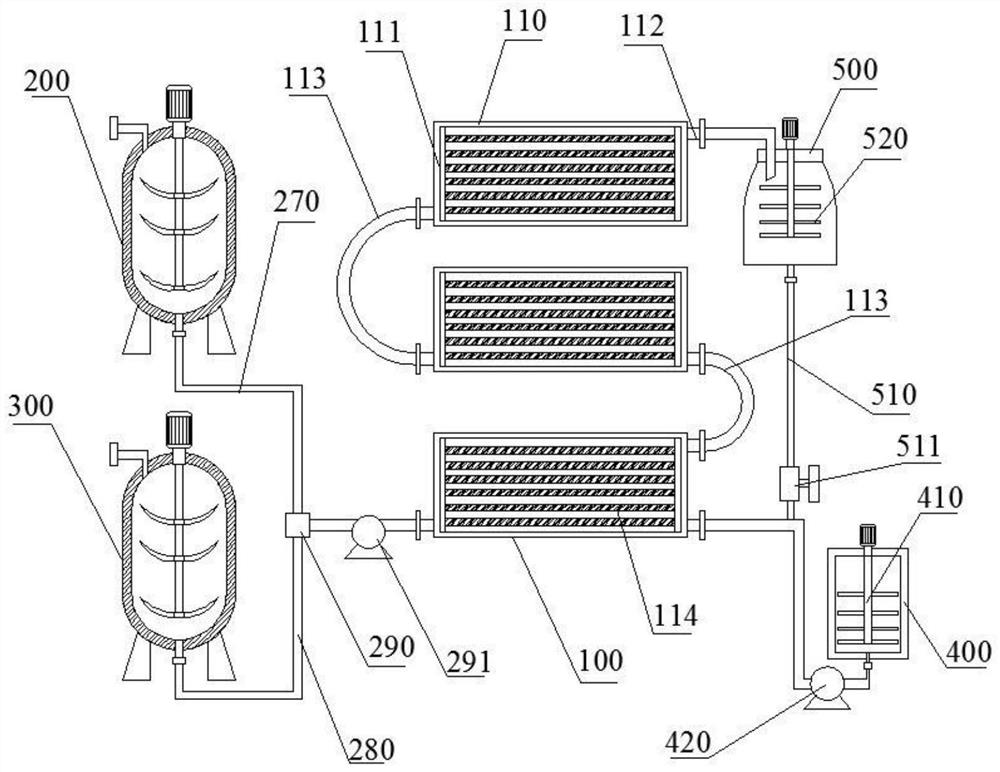

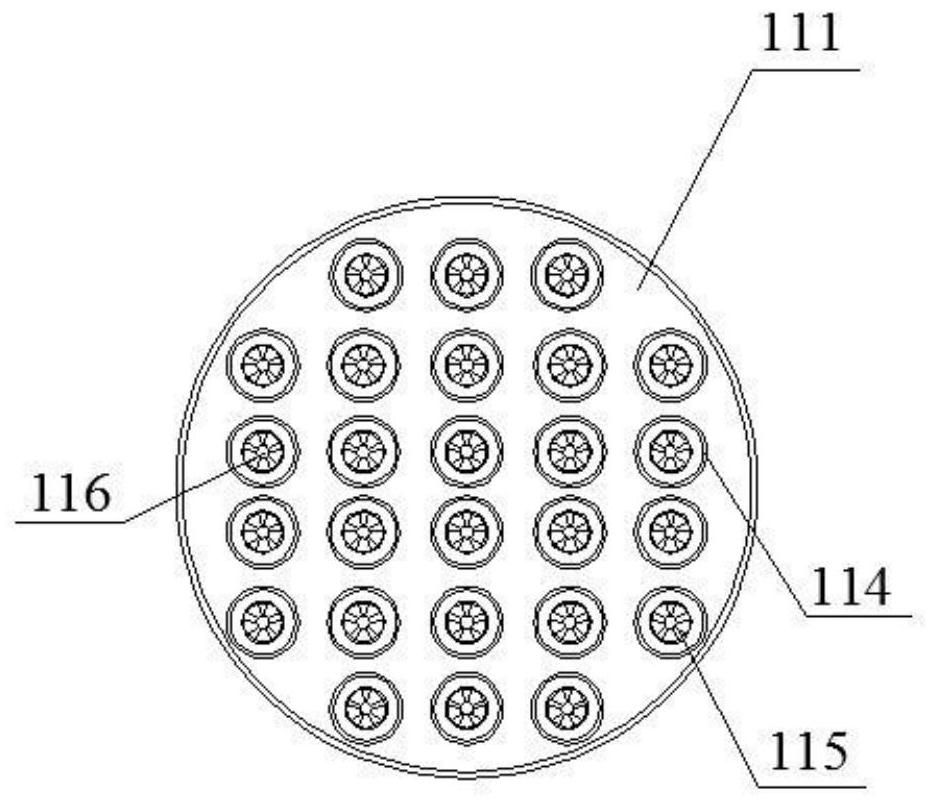

[0023] Such as figure 1 As shown, this embodiment provides a system for continuous flow membrane enzyme coupled directional conversion dipeptide, including membrane enzyme coupled reactor 100, first stirred tank 200, second stirred tank 300, biological enzyme tank 400, membrane enzyme coupled reaction The device 100 is formed by a plurality of membrane-enzyme coupled reaction units 110 equidistantly arranged from top to bottom. The first stirred tank 200 and the second stirred tank 300 are respectively filled with different amino acid raw materials. The first stirred tank 200 and the second stirred tank The amino acid raw materials in the stirring tank 300 enter from one end of the bottommost membrane enzyme coupling reaction unit 110 after being mixed, and the biological enzyme liquid in the biological enzyme tank 400 enters from the other end of the bottommost membrane enzyme coupling reaction unit 110; One end of the enzyme-coupled reaction unit 110 is connected to a liquid...

Embodiment 2

[0037] Such as Figure 1-4 As shown, this embodiment provides a method for continuous flow membrane enzyme-coupled directed conversion of dipeptides, comprising the following steps:

[0038] a. The amino acid raw materials in the first stirring tank 200 and the second stirring tank 300 are mixed through the first feeding pipe 270 and the second feeding pipe 280 respectively, and the flow rate is adjusted by the flow regulator 290 under the peristaltic action of the first peristaltic pump 291 Enter the membrane enzyme coupling reaction unit 110 at the bottom, and the biological enzyme liquid enters the membrane enzyme coupling reaction unit 110 at the bottom under the peristaltic action of the second peristaltic pump 420;

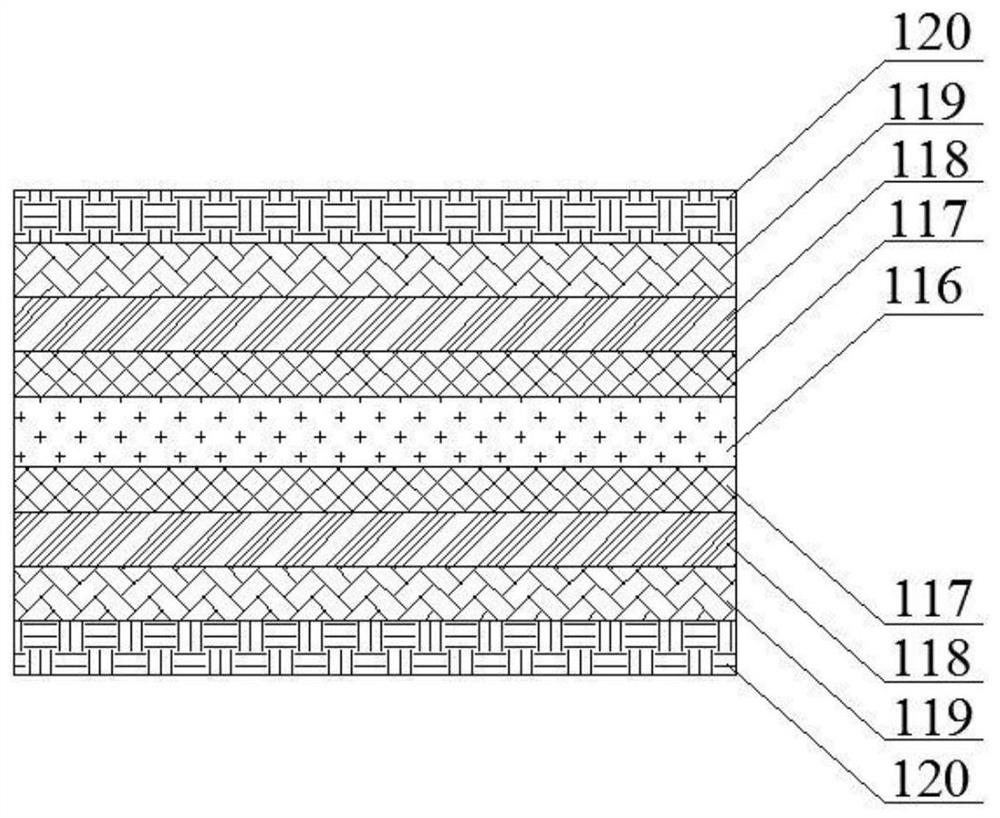

[0039] b. Amino acid raw material and biological enzyme liquid are mixed in the reaction tank body 111, enter the filtration through the diaphragm mesh layer 117 and the nanofiltration membrane layer 118 from the sealing material frame 115, and keep the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com