Cu-containing non-oriented silicon steel and production method thereof

A production method and technology for oriented silicon steel, applied in the production field of non-oriented silicon steel, can solve the problems of aggravating iron oxide scale, surface iron oxide scale, inheritance, etc., and achieve the effect of reducing energy consumption, ensuring the quality of the board surface and high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

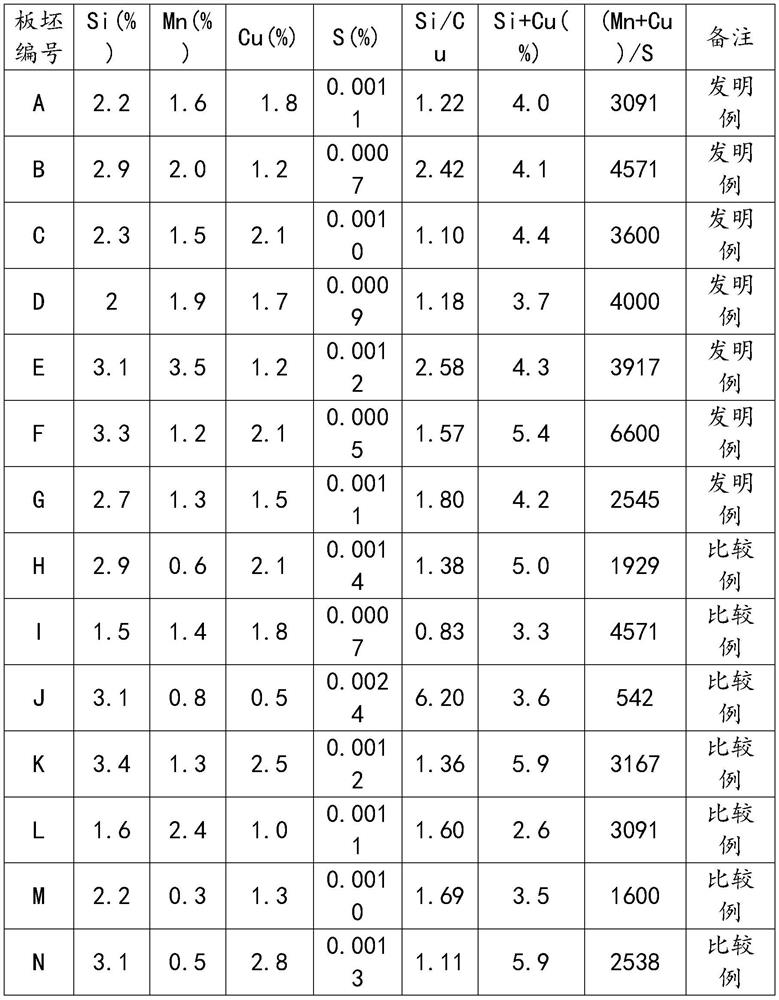

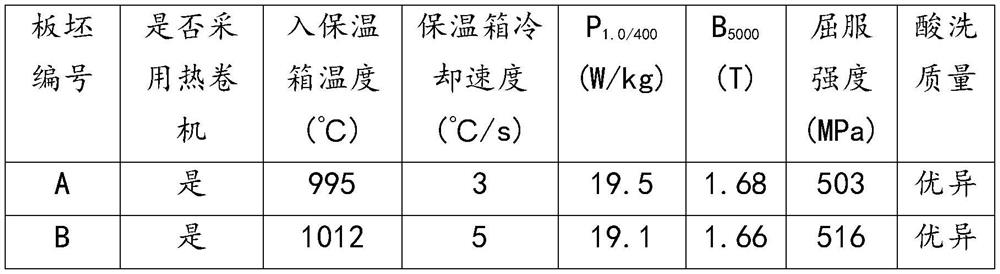

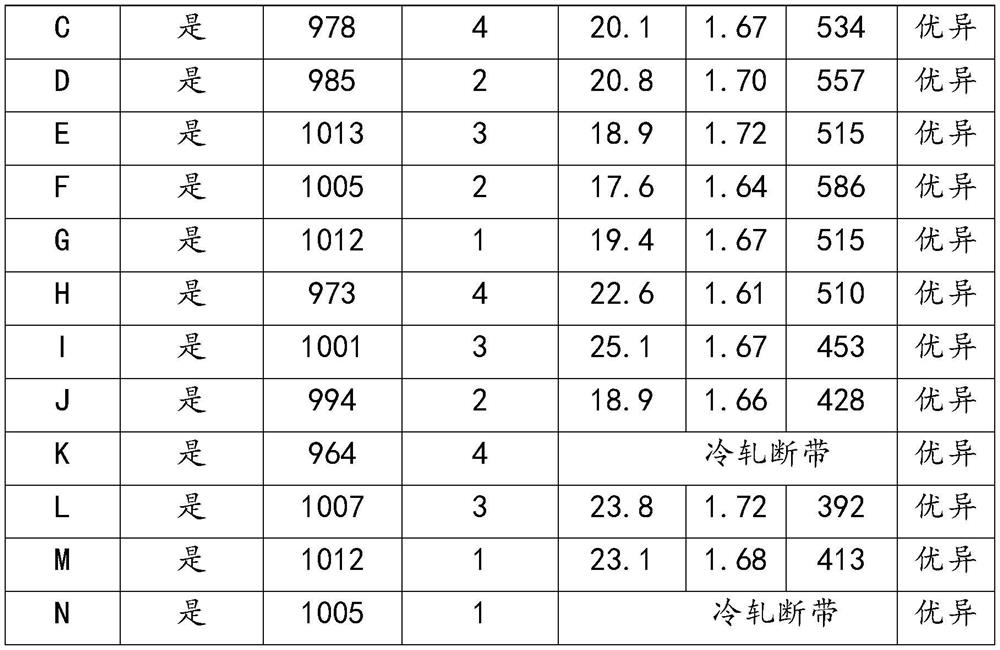

[0056] Converter steelmaking, continuous casting into slabs after vacuum treatment, the main chemical composition of the slabs is shown in Table 1, the rest is Fe, Als and other impurities, the slabs are heated and subjected to hot rolling and rough rolling, and the intermediate slabs are forced to be coiled by a hot coil machine , after uncoiling, the intermediate billet enters the insulation box, after exiting the insulation box, it is descaled under high pressure, finish rolling to 2.1mm, laminar flow cooling, coiling, cold rolling to 0.35mm after pickling, and finally annealing and coating treatment, the finished product is in N 2 The aging heat treatment was carried out at 500°C×1h under a protective atmosphere. The performance after aging and the quality of hot-rolled pickling are shown in Table 2.

[0057] Table 1 Slab Chemical Composition (wt,%)

[0058]

[0059] Table 2 process performance and pickling quality

[0060]

[0061]

Embodiment 2

[0063] The slab A of Example 1 is used for heating, and after heating, hot rolling and rough rolling are carried out. Part of the intermediate billet is forced to be coiled by a hot coil machine, and part of the intermediate billet enters the heat preservation box, followed by high-pressure descaling, and finish rolling to 2.1mm. Laminar cooling, coiling, cold rolling to 0.35mm after pickling, annealing and coating treatment, the final product is in N 2 480°C × 1.5h aging heat treatment was carried out under protective atmosphere. The performance after aging and the quality of hot-rolled pickling are shown in Table 3.

[0064] Table 3 process and finished product performance

[0065]

[0066]

[0067] In Table 3, the invention range of the temperature in the incubator is 960°C to 1060°C, preferably 990°C to 1030°C, and the temperature in the incubator in Invention Examples 4 to 6 adopts the preferred temperature, which takes into account the quality of hot-rolled picklin...

Embodiment 3

[0069] The slab F of Example 1 is used for heating, after heating, hot rolling and rough rolling are carried out, part of the intermediate billet is forced to be coiled by a hot coiler, and part of the intermediate billet enters the heat preservation box, followed by high-pressure descaling, and finish rolling to 2.2 mm. Laminar cooling, coiling, cold rolling to 0.35mm after pickling, and finally annealing and coating treatment, the final properties and surface conditions of the finished product are shown in Table 4.

[0070] Table 4 process and finished product performance

[0071]

[0072]

[0073] In Table 4, the invention range of temperature into the incubator is 946°C to 1046°C, preferably 976°C to 1016°C, and the temperature of the incubator in Invention Examples 4 to 5 adopts the preferred temperature, which takes into account the quality of hot-rolled pickling and the magnetic properties of the finished product; In Comparative Examples 1 and 2, the quality of ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com